Renault Clio II 2.0 2001 cambelt change instructions and replacement inteval. Full guide!

Special tools

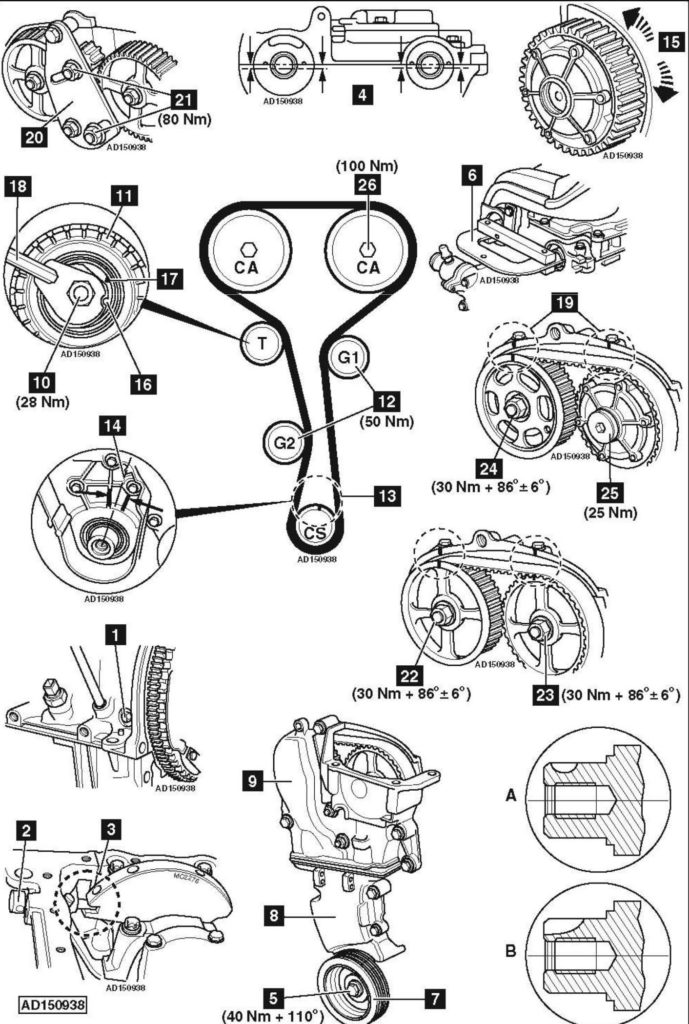

- Crankshaft timing pin – Renault No.Mot.1054.

- Camshaft setting bar – Renault No.Mot.1496.

- Camshaft adjusting wrench – Renault No.Mot.799-01.

- Camshaft locking tool – Renault No.Mot.1509/01.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 5,20 |

Valve timing procedures

Removal

NOTE: If timing belt is excessively noisy between idle and 2000 rpm a modified timing belt, tensioner pulley and guide pulleys should be fitted. Refer to a Renault dealer.

WARNING: Engines with variable valve timing: Mark camshaft sprockets and camshaft adjusters with chalk or paint prior to timing belt removal to assist alignment on installation.

-

- Raise and support front of vehicle.

- Remove:

- Engine top cover.

- RH front wheel.

- RH splash guard.

- Auxiliary drive belt.

NOTE: Auxiliary drive belt(s), tensioner pulley and guide pulley(s) MUST be replaced.

- Support engine.

- Remove:

- RH engine mounting.

- Blanking plugs from rear of camshafts.

- Blanking plug from cylinder block [1] .

- Turn crankshaft clockwise until grooves in rear of camshafts are just before horizontally aligned position.

NOTE: Grooves located below cylinder head upper face. - Insert timing pin through hole in cylinder block and into crankshaft [2] . Tool No.Mot.1054.

- Turn crankshaft slightly clockwise until timing pin locates in crankshaft [3] . Tool No.Mot.1054.

NOTE: Ensure timing pin not inserted into crankshaft web balance hole [3] . - Ensure grooves in rear of camshafts horizontally aligned [4] .

- Lock flywheel with large screwdriver. Slacken crankshaft pulley bolt [5] .

- Fit setting bar to rear of camshafts [6] . Tool No.Mot.1496.

- Remove:

- Crankshaft pulley bolt [5] .

- Crankshaft pulley [7] .

- Timing belt covers [8] & [9] .

- Slacken tensioner nut [10] .

- Allow tensioner pulley to move away from belt.

- Remove:

- Tensioner nut [10] .

- Tensioner pulley [11] .

- Guide pulleys (G1 & G2) [12] .

- Timing belt.

NOTE: DO NOT allow crankshaft sprocket to fall off crankshaft.

Installation

NOTE: Timing belt, tensioner pulley and guide pulleys MUST be replaced.

NOTE: There are two types of crankshaft fitted, type A and type B.

- Ensure timing pin located correctly in crankshaft [3] .

- Ensure grooves in rear of camshafts horizontally aligned [4] . If not: Turn camshafts. Use tool No.Mot.799-01.

- Ensure setting bar fitted correctly [6] .

- Ensure crankshaft keyway [13] located centrally between lugs on engine front housing [14] .

- Fit new guide pulleys (G1 & G2) [12] . Tighten bolts to 50 Nm.

- Fit new tensioner pulley [11] . Temporarily tighten nut to 7 Nm [10] .

NOTE: Ensure lug on rear of tensioner pulley located in groove in cylinder head. - Crankshaft type A:

- Remove crankshaft sprocket. Degrease sprocket. Degrease end of crankshaft. Refit crankshaft sprocket.

NOTE: F4R engines with variable valve timing: Ensure inlet camshaft VVT unit is locked within inlet camshaft sprocket (it should not be possible to rotate VVT unit to the left or right [15] ). If not: Replace VVT unit.

- Fit timing belt in anti-clockwise direction, starting at crankshaft sprocket. Ensure belt is taut on non-tensioned side.

- Fit new crankshaft pulley [7] .

- Fit new crankshaft pulley bolt [5] .

- Temporarily tighten crankshaft pulley bolt [5] . Leave 2-3 mm clearance between bolt contact face and crankshaft pulley [7] .

- Slacken tensioner nut [10] . Turn tensioner pulley clockwise until tensioner marks aligned [16] & [17] . Use 6 mm Allen key [18] .

- Temporarily tighten tensioner nut [10] . Tightening torque: 7 Nm.

- Mark camshaft sprockets and cylinder head with paint or chalk where indicated [19] .

- Lock flywheel with large screwdriver. Temporarily tighten crankshaft pulley bolt [5] . Tightening torque: 20 Nm.

- Remove timing pin [2] .

- Remove setting bar [6] .

- Lock flywheel with large screwdriver. Tighten crankshaft pulley bolt [5] . Tightening torque: 40 Nm + 110°.

- Crankshaft type B:

- Remove crankshaft sprocket. Degrease sprocket. Degrease end of crankshaft.

NOTE: F4R engines with variable valve timing: Ensure inlet camshaft VVT unit is locked within inlet camshaft sprocket (it should not be possible to rotate VVT unit to the left or right [15] ). If not: Replace VVT unit.

- Fit camshaft locking tool [20] . Tool No.Mot.1509/01.

- Tighten camshaft locking tool nuts [21] . Tightening torque: 80 Nm.

- F4P: Remove nut of each camshaft sprocket [22] & [23] .

- F4R: Remove exhaust camshaft sprocket nut [24] .

NOTE: Replace camshaft stud if loosened when removing nut.

- F4R: Remove blanking plug from inlet camshaft sprocket [25] .

- F4R: Remove inlet camshaft sprocket bolt [26] .

- Remove locking tool [20] .

- Remove camshaft sprockets.

- Degrease ends of camshafts and camshaft sprockets.

- F4P: Install camshaft sprockets. Finger tighten nut of each camshaft sprocket [22] & [23] .

- F4R: Install camshaft sprockets. Finger tighten nut and bolt of each camshaft sprocket [24] & [26] .

- Fit crankshaft sprocket.

- Fit timing belt.

- Slacken tensioner nut [10] . Turn tensioner pulley clockwise until tensioner marks aligned [16] & [17] . Use 6 mm Allen key [18] .

- Temporarily tighten tensioner nut [10] . Tightening torque: 7 Nm.

- Fit camshaft locking tool [20] .

- Tighten camshaft locking tool nuts [21] . Tightening torque: 80 Nm.

- F4P: Temporarily tighten nuts of each camshaft sprocket [22] & [23] . Tightening torque: 30 Nm.

- F4R: Temporarily tighten nut and bolt of each camshaft sprocket [24] & [26] . Tightening torque: 30 Nm.

- Remove locking tool [20] .

- Remove setting bar [6] .

- Remove timing pin [2] .

- Mark camshaft sprockets and cylinder head with paint or chalk where indicated [19] .

- Turn crankshaft two turns clockwise until just before setting position [19] .

- Insert timing pin through hole in cylinder block and into crankshaft [2] .

- Turn crankshaft slightly clockwise. Ensure timing pin located correctly in crankshaft [3] .

NOTE: Ensure timing pin not inserted into crankshaft web balance hole.

- Ensure setting position marks aligned [19] .

- Ensure tensioner pulley marks aligned [16] & [17] . If not: Repeat tensioning procedure.

- Tighten tensioner nut [10] . Tightening torque: 28 Nm.

- Fit setting bar [6] .

- Fit locking tool [20] .

- Tighten camshaft locking tool nuts [21] . Tightening torque: 80 Nm.

- F4P: Fit new nuts to camshaft sprockets [22] & [23] . Tightening torque: 30 Nm + 86°±6°.

- F4R: Fit new nut to exhaust camshaft sprocket [24] . Tightening torque: 30 Nm + 86°±6°.

- F4R: Fit new bolt to inlet camshaft sprocket [26] . Tightening torque: 100 Nm.

- F4R: Fit blanking plug to inlet camshaft sprocket [25] . Tightening torque: 25 Nm.

- Remove locking tool [20] .

- Remove setting bar [6] .

- Remove timing pin [2] .

- Fit new crankshaft pulley [7] .

- Fit new crankshaft pulley bolt [5] .

- Lock flywheel with large screwdriver. Tighten crankshaft pulley bolt [5] . Tightening torque: 40 Nm + 110°.

- All engines:

- Turn crankshaft two turns clockwise until just before setting position [19] .

- Insert timing pin through hole in cylinder block and into crankshaft [2] .

- Turn crankshaft slightly clockwise. Ensure timing pin located correctly in crankshaft [3] .

- NOTE: Ensure timing pin not inserted into crankshaft web balance hole.

- Ensure camshaft setting bar can be fitted easily [6] .

- Ensure tensioner pulley marks aligned [16] & [17] . If not: Repeat tensioning procedure.

- Tighten tensioner nut [10] . Tightening torque: 28 Nm.

- Remove:

- Timing pin [2] .

- Setting bar [6] .

- Refit blanking plug [1] .

- Fit new blanking plugs to rear of camshafts.

NOTE: DO NOT start engine without auxiliary drive belt fitted as damage may occur to crankshaft pulley. - Install components in reverse order of removal.