Citroen Jumper 2.2HDi 2003 cambelt change instructions and replacement inteval. Full guide!

Special tools

- Crankshaft timing pin – Renault No.Mot.1489.

- Camshaft timing pin – Renault No.Mot.1430.

- Engine support tool – Renault No.Mot.1453.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 2,70 |

Valve timing procedures

Removal

NOTE: If timing belt has failed, it is possible that the camshaft sprocket key has been damaged which would cause incorrect valve timing.

- Raise and support front of vehicle.

- Remove:

- RH front wheel.

- RH splash guard.

- Engine undershield.

- Auxiliary drive belt.

NOTE: Auxiliary drive belt(s), tensioner pulley and guide pulley(s) MUST be replaced.

- Support engine. Use tool No.1453.

- Remove:

- RH engine mounting.

- RH engine mounting bracket.

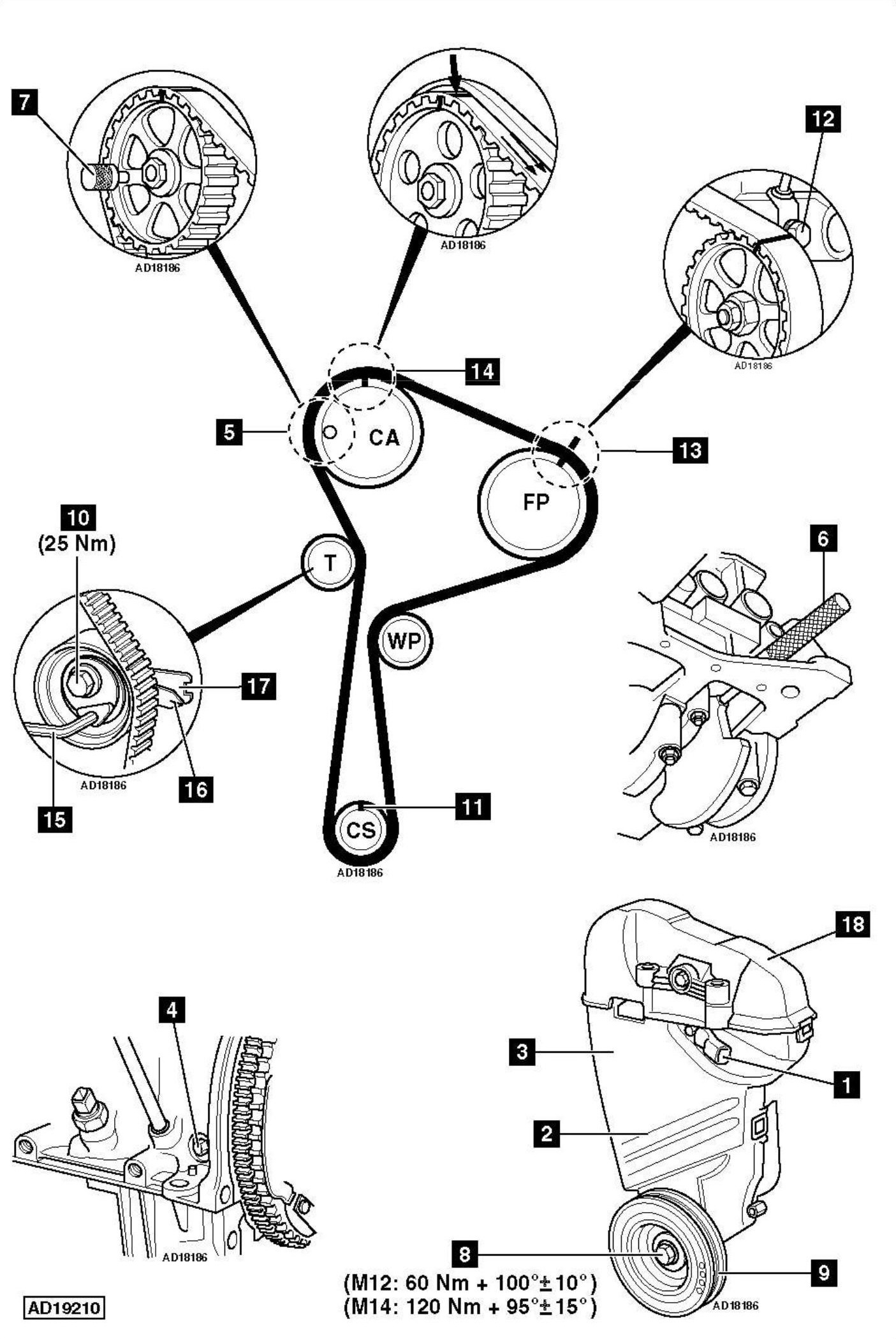

- Timing belt upper cover [18] .

- Camshaft position (CMP) sensor [1] .

- Unclip fuel pipes from timing belt lower cover [2] . Move to one side.

- Remove:

- Timing belt lower cover [3] .

- Blanking plug from cylinder block [4] .

- Turn crankshaft clockwise until camshaft sprocket timing pin locating hole almost aligned with hole in cylinder head [5] .

- Insert crankshaft timing pin [6] . Tool No.Mot.1489.

- Turn crankshaft slightly until crankshaft web stops against timing pin [6] .

- Insert camshaft timing pin [7] . Tool No.1430.

- Remove timing pins [6] & [7] .

- Lock flywheel with large screwdriver. Slacken crankshaft pulley bolt [8] .

- Remove:

- Crankshaft pulley bolt [8] .

- Crankshaft pulley [9] .

- Slacken tensioner bolt [10] . Move tensioner away from belt.

Installation

NOTE: Timing belt and tensioner pulley MUST be replaced.

- Insert timing pins [6] & [7] .

- Ensure crankshaft keyway pointing vertically upwards [11] .

- Ensure high-pressure fuel pump sprocket timing mark aligned with bolt head [12] .

- Fit timing belt. Ensure marks on belt aligned with marks on sprockets [13] & [14] . Ensure belt is taut on non-tensioned side.

- Turn tensioner anti-clockwise until pointer at lower position [16] . Use 6 mm Allen key [15] . Tighten tensioner bolt [10] . Tightening torque: 25 Nm.

- Fit crankshaft pulley [9] .

- Lock flywheel with large screwdriver.

- Tighten crankshaft pulley bolt [8] .

- M12: Tightening torque: 60 Nm + 100±10°. Use new bolt.

- M14: Tightening torque: 120 Nm + 95±15°. Use new bolt.

- Remove timing pins [6] & [7] .

- Turn crankshaft two turns clockwise until camshaft sprocket locating hole aligned [5] .

- Insert timing pin [6] . Rock crankshaft slightly to ensure timing pin located correctly.

- Insert camshaft timing pin [7] .

- Remove timing pins [6] & [7] .

- Slacken tensioner bolt [10] by a maximum of one turn whilst holding 6 mm Allen key [15] .

- Turn Allen key clockwise until pointer [16] aligns with notch [17] . Tighten tensioner bolt [10] . Tightening torque: 25 Nm.

NOTE: DO NOT start engine without auxiliary drive belt fitted as damage may occur to crankshaft pulley. - Install components in reverse order of removal.