Opel Meriva 1.7 CDTi 2014 cambelt change instructions and replacement inteval. Full guide!

Special tools

- Except Astra-J/Mokka: Auxiliary drive belt tensioner locking tool – Kent Moore No.KM-6130.

- Astra-J/Mokka: Auxiliary drive belt tensioner adjusting tool – No.EN-913-A.

- Astra-J/Mokka: Auxiliary drive belt tensioner locking tool – No.EN-48952.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – C & A | 1,40 |

| Camshaft drive belt/chain – R & I | 1,50 |

Valve timing procedures

Removal

- Raise and support vehicle.

- Remove:

- Engine top cover.

- Air filter housing and air intake hose.

- Engine undershield.

- RH front wheel.

- RH inner wing panel.

- Turn auxiliary drive belt tensioner to release tension on belt. Use ring spanner or tool No.EN-913-A.

- Lock auxiliary drive belt tensioner. Use tool No.EN-48952 or No.KM-6130.

- Remove:

- Auxiliary drive belt.

- NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

- Crankshaft pulley bolts [1] .

- Crankshaft pulley [2] .

- Support engine.

- Remove:

- RH engine mounting.

- RH engine mounting bracket.

- Camshaft position (CMP) sensor.

- Timing belt upper cover [3] .

- Timing belt lower cover [4] .

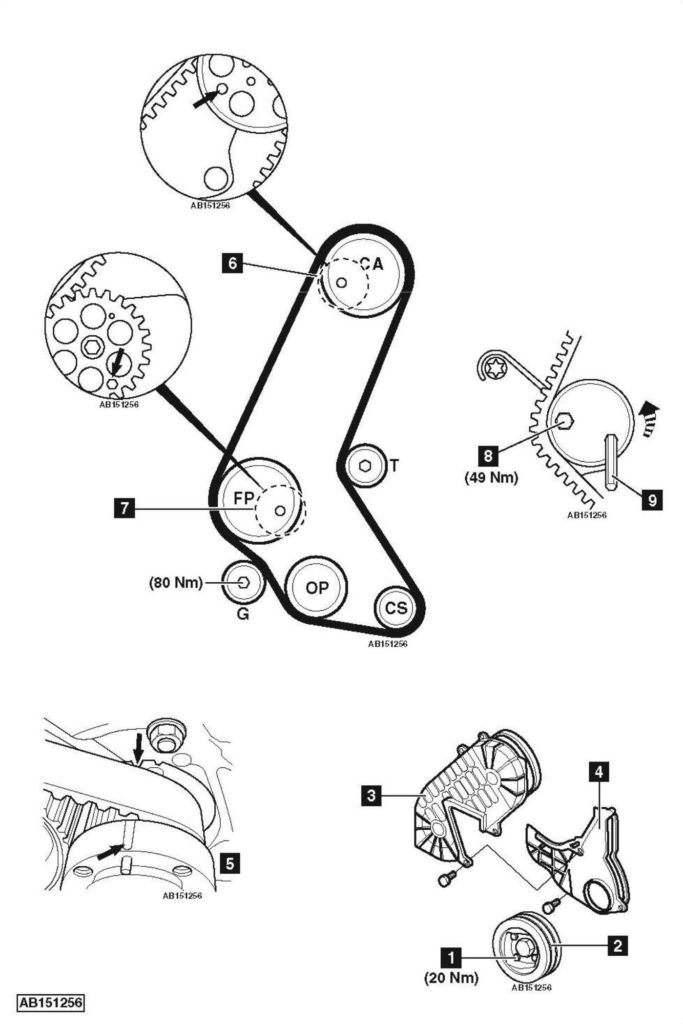

- Turn crankshaft to TDC on No.1 cylinder. Ensure timing marks aligned [5] .

- Ensure camshaft sprocket aligning hole at 8 o’clock position.

- If not: Turn crankshaft one turn clockwise.

- Screw suitable locking bolts into camshaft sprocket and high-pressure fuel pump sprocket [6] & [7]

- Slacken tensioner bolt [8] .

- Turn tensioner pulley 90° anti-clockwise. Use Allen key [9] . Lightly tighten bolt [8] .

- Remove timing belt.

NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

Installation

- Ensure locking bolts located correctly [6] & [7] .

- Ensure crankshaft sprocket mark aligned with notch [5] .

- Check tensioner pulley and guide pulley for smooth operation.

- Fit timing belt in clockwise direction, starting at crankshaft sprocket. Ensure belt is taut between sprockets.

NOTE: Ensure directional arrows point in direction of rotation. - Slacken tensioner bolt [8] .

- Allow tensioner to tension belt.

- Tighten tensioner bolt [8] . Tightening torque: 49 Nm.

- Remove locking bolts from sprockets [6] & [7] .

- Turn crankshaft 2 turns clockwise to TDC on No.1 cylinder.

- Ensure crankshaft sprocket mark aligned with notch [5] .

- Ensure locking bolts can be installed [6] & [7] .

- If not: Repeat installation procedure.

- Remove locking bolts [6] & [7] .

- Install components in reverse order of removal.

- Tighten crankshaft pulley bolts [1] . Tightening torque: 20 Nm.

NOTE: Observe direction of rotation marks on auxiliary drive belt.

NOTE: If battery has been disconnected, re-initialization of window and sunroof motors and steering position sensor may be required.