Honda Accord 2.2 1993-98 cambelt change instructions and replacement inteval. Full guide!

Special tools

- Balancer shaft locking pin – Honda No.07LAG-PT20100.

- Crankshaft pulley holding tool – Honda Nos.07JAB-0010200 & 07MAB-PY30100.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 2,30 |

Valve timing procedures

Removal

NOTE: Normal direction of crankshaft rotation is anti-clockwise. Balancer shaft belt must be removed before removing timing belt.

- Support engine.

- Remove:

- Lower splash guard.

- Auxiliary drive belts.

- PAS pump. DO NOT disconnect hoses.

- Cylinder head cover.

- Timing belt upper cover [3] .

- LH engine mounting.

- Dipstick and tube.

- Rubber seal for adjusting nut [6] . DO NOT slacken nut.

- Crankshaft pulley [5] . Use tool Nos.07JAB-0010200 & 07MAB-PY30100.

- Timing belt lower cover [4] .

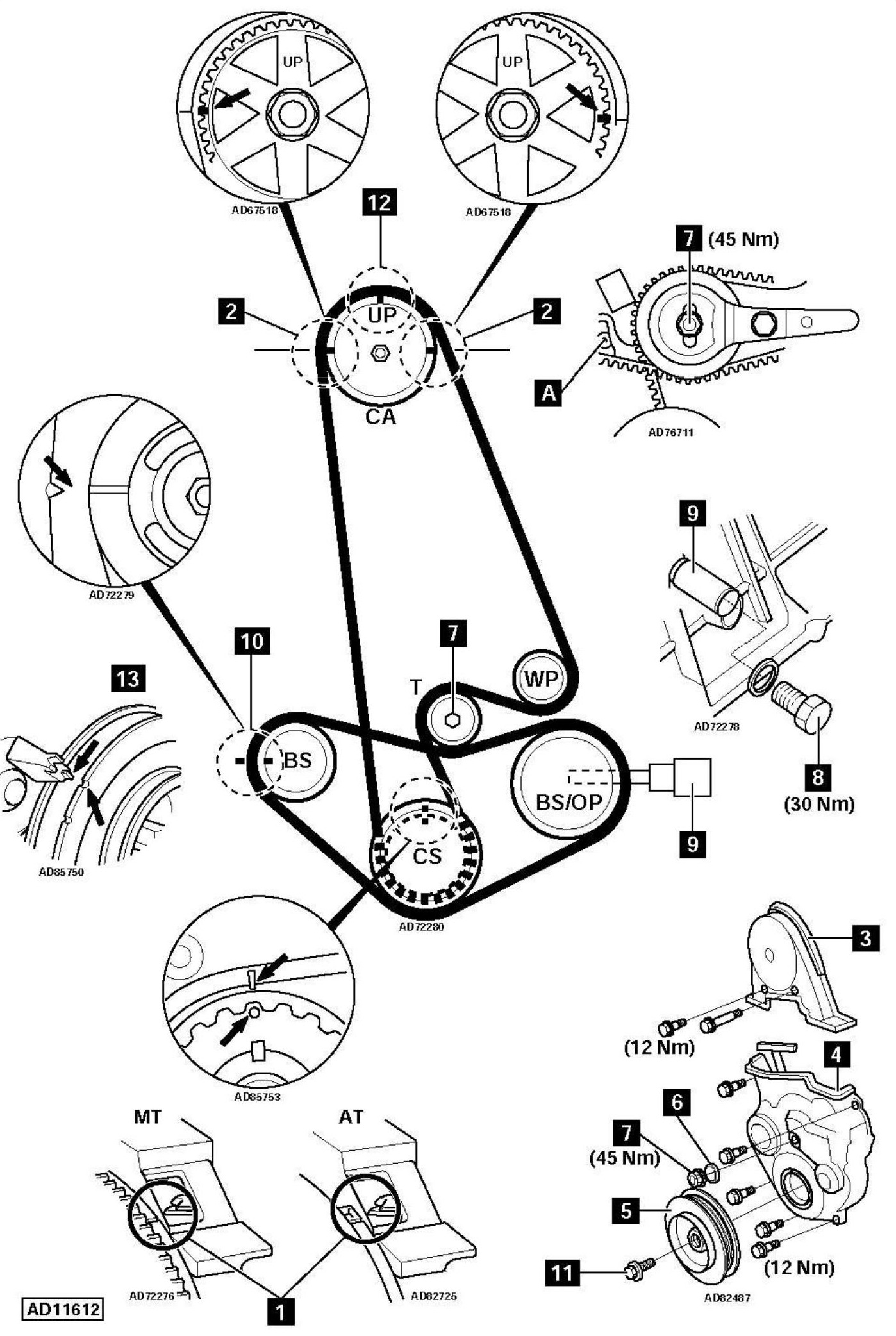

- Temporarily fit crankshaft pulley. Turn crankshaft to TDC on No.1 cylinder. Ensure white flywheel timing mark and camshaft timing marks aligned [1] & [2] . Ensure ‘UP’ mark on camshaft sprocket at top [12] .

NOTE: F22Z2 engines have TDC marks on crankshaft pulley and timing belt lower cover [13] . - Fit 6 mm bolt at [A] to lock tensioner arm.

- Slacken tensioner nut [7] . Move tensioner away from belt. Lightly tighten nut.

- Remove balancer shaft belt.

- Slacken 6 mm bolt [A] . Slacken tensioner nut [7] . Move tensioner away from belt and lightly tighten nut.

- Remove:

- Crankshaft pulley [5] .

- Timing belt.

Installation

- Ensure timing marks aligned [1], [2] & [13] .

- Fit timing belt in anti-clockwise direction, starting at crankshaft sprocket. Ensure belt is taut between sprockets.

- Ensure 6 mm bolt is slack [A] .

- Slacken tensioner nut and tighten to 45 Nm [7] .

- Temporarily fit crankshaft pulley. Turn crankshaft slowly six turns anti-clockwise to settle belt. Ensure timing marks aligned.

- Turn crankshaft slowly anti-clockwise until three teeth of camshaft sprocket have passed timing marks [2] .

- Slacken tensioner nut and tighten to 45 Nm [7] .

- Turn crankshaft to TDC on No.1 cylinder. Ensure timing marks aligned.

- Tighten 6 mm bolt [A] to lock tensioner arm.

- Remove blanking plug [8] . Insert balancer shaft locking pin. Tool No.07LAG-PT20100 [9] . Turn rear balancer shaft sprocket until locking pin locates in hole in shaft.

- Align front balancer shaft timing marks [10] .

- Remove crankshaft pulley [5] .

- Fit balancer shaft belt.

- Slacken tensioner nut [7] .

- Remove balancer shaft locking pin [9] . Fit blanking plug and tighten to 30 Nm.

- Fit crankshaft pulley [5] . Turn crankshaft one turn anti-clockwise.

- Tighten tensioner nut [7] . Tightening torque: 45 Nm.

- Remove 6 mm bolt [A] .

- Install components in reverse order of removal.

- Tighten crankshaft pulley bolt [11] . Tightening torque: F18A3/F20Z1/2/3: 220 Nm. Except F18A3/F20Z1/2/3: 245-250 Nm.