Replacement Interval Guide

- Vauxhall recommend replacement as follows:

- →95MY – replacement every 54,000 miles or 6 years, whichever occurs first.

- 96-98MY – replacement every 60,000 miles or 6 years, whichever occurs first.

- 98½MY→ – replacement every 80,000 miles.

- The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston damage in the event of a timing belt failure is MOST LIKELY to occur. A compression check of all cylinders should be performed before removing the cylinder head.

Repair Times – hrs

| Remove & install: | |

|---|---|

| Monterey (→1998) | 2,00 |

| Monterey (1999→) | 1,60 |

| AC | +0,20 |

| Frontera | 1,90 |

Special Tools

- None required.

Special Precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Removal

- Remove:

- Air filter and hose.

- Upper radiator shroud.

- Lower radiator shroud.

- Cooling fan and viscous coupling.

- Auxiliary drive belt(s).

- Cooling fan pulley.

- PAS pump pulley.

- Auxiliary drive belt tensioner.

- Oil cooler hose.

- Crankshaft pulley bolt [1] .

- Crankshaft pulley [2] .

- Timing belt RH upper cover [3] .

- Timing belt LH upper cover [4] .

- Timing belt lower cover [5] .

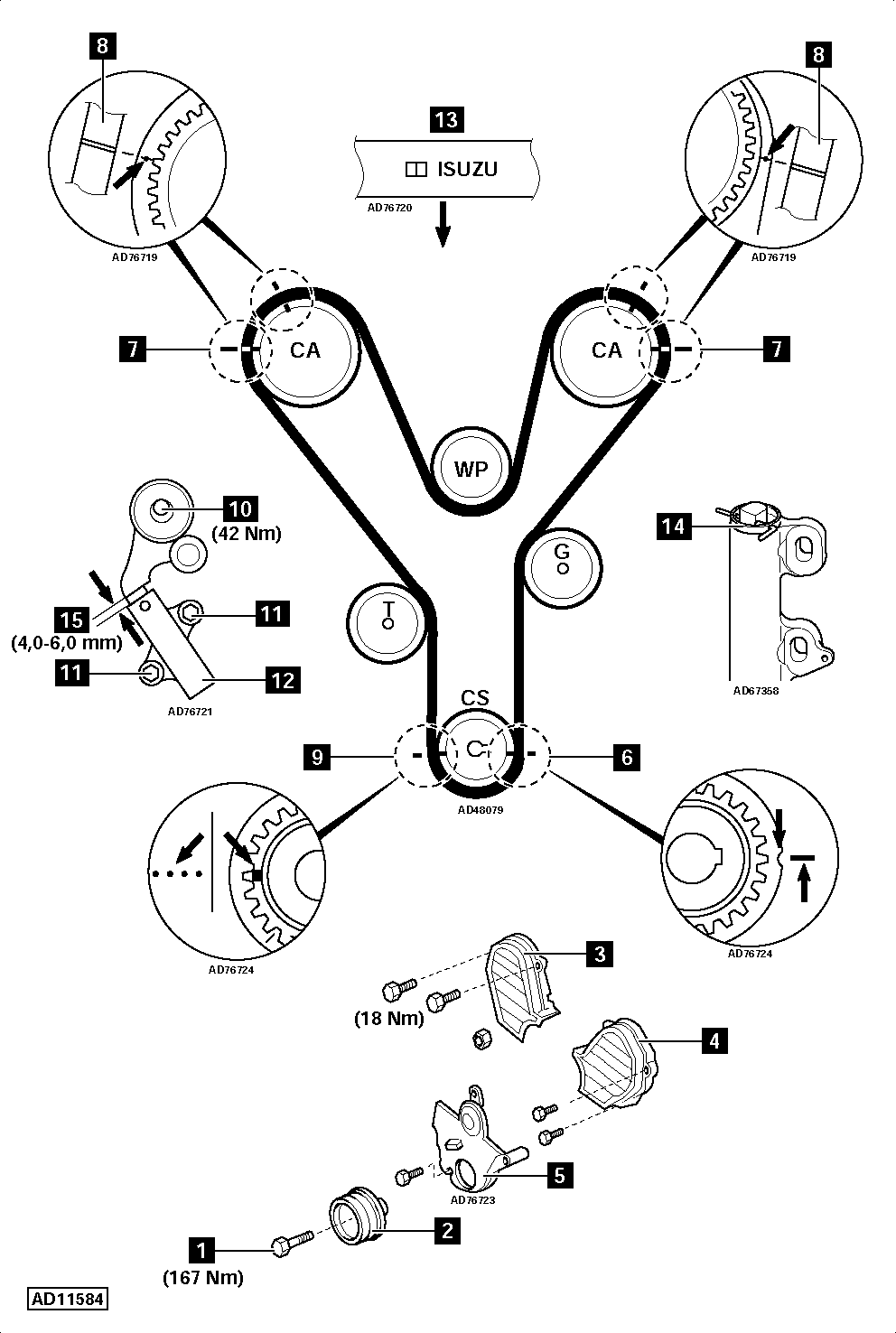

- Temporarily fit crankshaft pulley bolt [1] . Turn crankshaft clockwise until timing marks aligned [6] & [7] .

NOTE: Some engines have alternative location for timing marks of camshaft sprockets [7] .

- Early engines with eccentric tensioner pulley:

- Slacken tensioner pulley bolt [10] .

- Turn tensioner clockwise away from belt.

- Lightly tighten bolt.

- Remove:

- Automatic tensioner unit bolts [11] .

- Automatic tensioner unit [12] .

- Timing belt.

Installation

- Ensure timing marks aligned [6] & [7] .

NOTE: DOHC: Due to uneven gear ratio between camshafts and sprocket idler shafts, correct camshaft alignment may have been lost if engine has been overhauled or timing belt was broken.

- Fit timing belt in anti-clockwise direction, starting at crankshaft sprocket. Ensure belt is taut between sprockets on non-tensioned side.

- Ensure marks on belt [8] & [9] aligned with marks on sprockets [6] & [7] .

NOTE: Letters on belt should be readable from front of engine [13] .

- Slowly compress pushrod into tensioner body [12] with a force of approximately 100 kg until holes aligned.

- Retain pushrod with 1,4 mm diameter pin through hole in tensioner body [14] .

- Install automatic tensioner unit to cylinder block. Tighten bolts [11] . Monterey →1998: 19 Nm. Monterey 1999→/Frontera: 25 Nm.

- Early engines with eccentric tensioner pulley:

- Slacken tensioner pulley bolt [10] .

- Turn tensioner anti-clockwise to tension belt.

- Tighten bolt to 42 Nm.

- Remove pin from tensioner body to release pushrod.

- Temporarily fit crankshaft pulley [2] .

- Turn crankshaft slowly two turns clockwise. Ensure timing marks aligned [6] & [7] .

- Check extended length of pushrod is 4,0-6,0 mm [15] .

- If not:

- Slowly compress pushrod into tensioner body [12] with a force of approximately 100 kg until holes aligned.

- Retain pushrod with 1,4 mm diameter pin through hole in tensioner body [14] .

- Install automatic tensioner unit to cylinder block. Tighten bolts [11] . Monterey →1998: 19 Nm. Monterey 1999→/Frontera: 25 Nm.

- Early engines with eccentric tensioner pulley:

- Slacken tensioner pulley bolt [10] .

- Turn tensioner anti-clockwise to tension belt.

- Tighten bolt to 42 Nm.

- Remove pin from tensioner body to release pushrod.

- Temporarily fit crankshaft pulley [2] .

- Turn crankshaft slowly two turns clockwise.

- Check extended length of pushrod is 4,0-6,0 mm [15] .

- Install components in reverse order of removal.

- Tighten crankshaft pulley bolt [1] . Tightening torque: 167 Nm.