Vauxhall/Opel Zafira 2,0d DTi cambelt change instructionts and replacement inteval. Full guide!

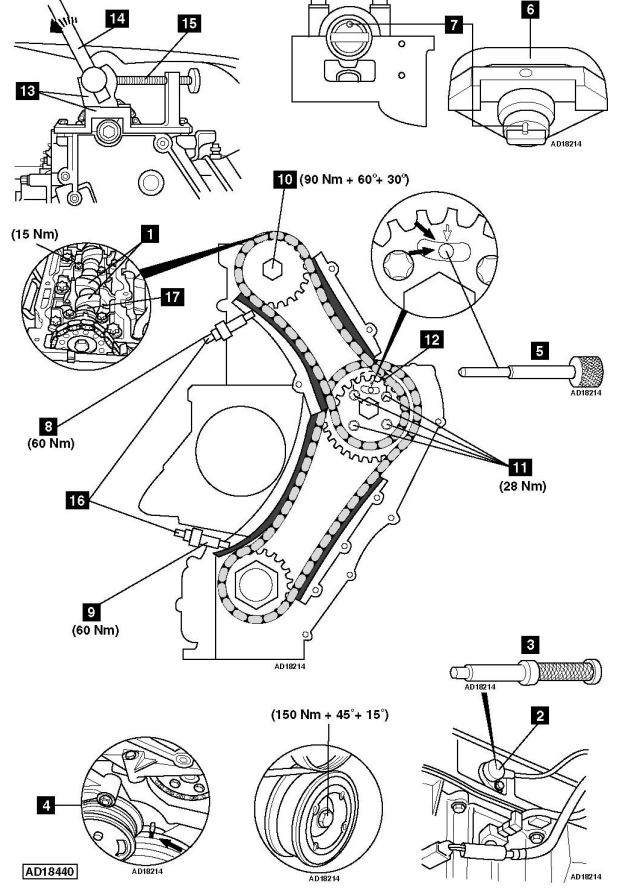

Special tools

- Camshaft locking tool – No.KM-932.

- Camshaft sprocket holding tool – No.KM-933.

- Crankshaft locking pin – No.KM-929.

- Crankshaft pulley holding tool – No.KM-930 or KM-977-1/956-1.

- Injection pump locking pin – No.KM-927.

General precautions

- Disconnect battery earth lead.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT use special tools listed above to lock engine when slackening sprocket bolts.

- Observe tightening torques.

- Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

- Check diesel injection pump timing after resetting valve timing.

Valve timing procedures

- Turn crankshaft until just before crankshaft pulley timing marks aligned.

- Ensure No.1 cylinder camshaft lobes are facing upwards [1] .

- Remove crankshaft position (CKP) sensor [2] .

- Slowly turn crankshaft clockwise until locking pin can be inserted in crankshaft [3] . Tool No.KM-92

- Engine at TDC on No.1 cylinder.

- Ensure crankshaft pulley timing marks aligned [4] .

- Insert locking pin in hole in injection pump [5] . Tool No.KM-927.

- Fit locking tool to rear of camshaft [6] . Tool No.KM-932.

- Ensure peg locates in camshaft [7] .

- Injection pump timing adjustment:

- Ensure crankshaft locking pin inserted [3] . Tool No.KM-929.

- Remove timing chain tensioners [8] & [9] . Note installation positions.

- Remove camshaft sprocket bolt [10] . Fit new bolt.

- Tighten bolt until camshaft sprocket turns freely but does not tilt.

- Remove injection pump sprocket bolts [11] . Fit new bolts (bolt classification – 10.9).

NOTE: Injection pump sprocket may have 5 bolts.

- Turn injection pump sprocket until arrow and hole aligned [12] .

- Insert locking pin in hole in injection pump [5] . Tool No.KM-927.

- Install lower timing chain tensioner [9] . Tightening torque: 60 Nm.

- Remove injection pump locking pin [5] .

- Tighten injection pump sprocket bolts [11] . Tightening torque: 28 Nm.

- Adjust valve timing.

Valve timing procedures:

- Ensure crankshaft locking pin inserted [3] . Tool No.KM-929.

- Ensure injection pump locking pin inserted [5] . Tool No.KM-927.

- Ensure upper timing chain tensioner removed [8] .

- Ensure new camshaft sprocket bolt tightened until camshaft sprocket turns freely but does not tilt.

- Ensure arrow on injection pump sprocket and hole aligned [12] .

- Fit locking tool to rear of camshaft [6] . Tool No.KM-932.

- Ensure peg locates in camshaft [7] .

- Install camshaft sprocket holding tool [13] . Tool No.KM-933.

- Apply slight anti-clockwise pressure on camshaft sprocket using lever [14] . Retain lever in position using locking bolt

- [15] .

- Ensure injection pump locking pin can be removed and inserted easily [5] .

- Tighten camshaft sprocket bolt [10] . Tightening torque: 90 Nm + 60° + 30°.

- Install upper timing chain tensioner [8] . Tightening torque: 60 Nm.

- Turn crankshaft 2 turns clockwise to TDC on No.1 cylinder.

- Install special tools and check valve timing and injection pump timing.

- Timing chain tensioner with release pin [16] :

- After installation, release timing chain tensioner by pressing pin until click is heard.

- Ensure pin can be pushed in fully with thumb pressure and returns to original position.

NOTE: Engine oil pressure will prevent release pin from being pushed in.

- Camshaft rotation can be prevented using spanner at position shown [17] .

- Auxiliary drive belt tensioner:

- Store in upright position.

- Bleed incorrectly stored tensioner by repeated compression in upright position.

NOTE: Crankshaft pulley central bolt MUST only be used once.