Replacement Interval Guide

- Peugeot recommend:

- 2007:

- Replacement every 160,000 miles or 10 years under normal conditions.

- Replacement every 108,000 miles or 10 years under adverse conditions.

- 2008→:

- Replacement every 160,000 miles or 10 years under normal conditions.

- Replacement every 112,500 miles or 10 years under adverse conditions.

- The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston damage in the event of a timing belt failure is MOST LIKELY to occur. A compression check of all cylinders should be performed before removing the cylinder head.

Repair Times – hrs

| Remove & install | 3,20 |

| AC | +1,00 |

Special Tools

- Auxiliary drive belt tensioner tool – Peugeot Nos.(-).0188.Z/Q1.

- Camshaft sprocket locking tool – Peugeot No.(-).0188.M.

- Crankshaft sprocket centralizing tool – Peugeot No.(-).0188.AH.

- Flywheel timing pin – Peugeot No.(-).0188.Y.

- Flywheel locking tool – Peugeot No.(-).0188.F.

- Timing belt clamp – Peugeot No.(-).0188.AD.

Special Precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Removal

- Raise and support front of vehicle.

- Remove:

- Scuttle panel.

- RH front wheel.

- RH splash guard.

- Engine undershield.

- Engine top cover (if fitted).

- Auxiliary drive belt. Use tool Nos.(-).0188.Z/Q1.NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

- Turbocharger/intercooler lower air hose(s).

- Air resonator and air intake pipe.

- LH subframe support bracket.

- Disconnect crankshaft position (CKP) sensor.

- Unclip wiring harness from timing belt upper cover.

- Disconnect fuel pipes from timing belt upper cover.

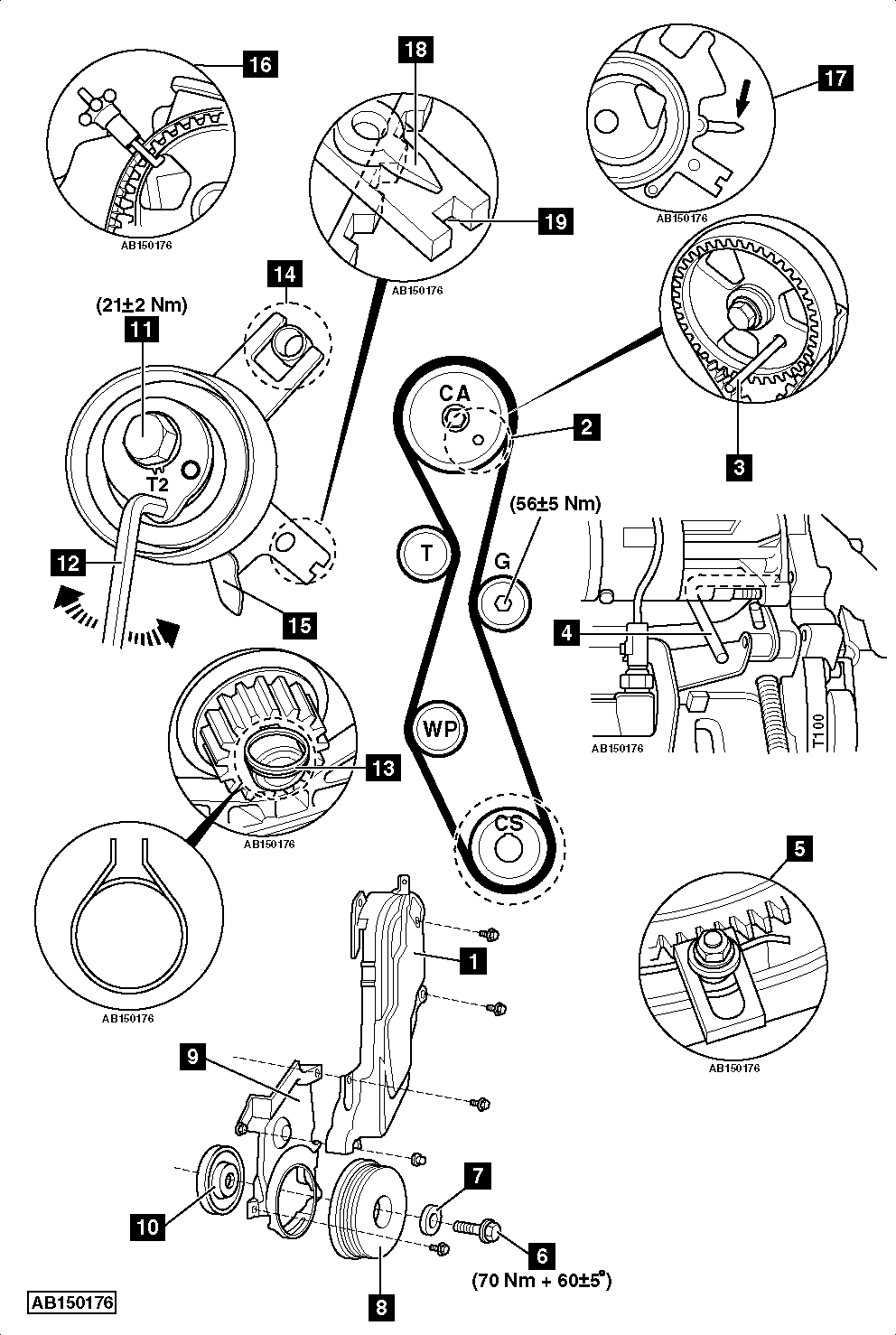

- Remove timing belt upper cover [1] .

- Turn crankshaft clockwise to setting position. Ensure camshaft sprocket timing hole at 4 o’clock position [2] .

- Insert:

- Camshaft sprocket locking tool [3] . Tool No.(-).0188.M.

- Flywheel timing pin behind starter motor [4] . Tool No.(-).0188.Y.

- Fit flywheel locking tool [5] . Tool No.(-).0188.F.

- Remove:

- Crankshaft pulley centre cap.

- Crankshaft pulley bolt [6] .

- Crankshaft pulley spacer [7] .

- Crankshaft pulley [8] .

- Timing belt lower cover [9] .

- Reluctor [10] .NOTE: Ensure reluctor is not damaged.

- Crankshaft position (CKP) sensor.

- Slacken tensioner pulley bolt [11] .

- Turn tensioner clockwise to release tension on belt. Use Allen key [12] .

- Remove timing belt.

Installation

NOTE: DO NOT refit used belt.

- Check tensioner pulley and guide pulley for smooth operation.

- Check water pump sprocket for smooth operation.

- Check crankshaft sprocket has free movement on keyway.

- Ensure flywheel locking tool located correctly [5] .

- Ensure flywheel timing pin located correctly [4] .

- Ensure camshaft sprocket locking tool located correctly [3] .

- Centralise crankshaft sprocket. Use tool No.(-).0188.AH [13] .

- Ensure tensioner retaining lug is properly engaged [14] .

- Ensure tensioner pulley pointer at position shown [15] .

- Secure timing belt to camshaft sprocket with clamp [16] . Use tool No.(-).0188.AD.

- Fit timing belt in following order:

- Guide pulley.

- Crankshaft sprocket.

- Water pump sprocket.

- Tensioner pulley.

- Ensure belt is taut between camshaft sprocket and guide pulley.

- Remove timing belt clamp [16] .

- Turn tensioner pulley anti-clockwise until pointer in position as shown [17] . Use Allen key [12] .

- Tighten tensioner pulley bolt [11] . Tightening torque: 21±2 Nm.

- Remove tool [13] .

- Install:

- Reluctor [10] .NOTE: Ensure reluctor is not damaged.

- Crankshaft pulley [8] .

- Crankshaft pulley spacer [7] .

- Crankshaft pulley bolt [6] .

- Temporarily tighten crankshaft pulley bolt [6] . Tightening torque: 50±10 Nm.

- Remove tools [3] , [4] & [5] .

- Turn crankshaft four turns clockwise.

- Install:

- Camshaft sprocket locking tool [3] .

- Flywheel timing pin [4] .

- Flywheel locking tool [5] .

- Remove:

- Crankshaft pulley bolt [6] .

- Crankshaft pulley spacer [7] .

- Crankshaft pulley [8] .

- Reluctor [10] .

NOTE: Ensure reluctor is not damaged.

- Hold tensioner pulley in position. Use Allen key [12] .

- Slacken tensioner pulley bolt [11] .

- Turn tensioner pulley clockwise until pointer aligned with notch [18] & [19] . Use Allen key [12] .NOTE: If pointer passes notch [18] , repeat tensioning procedure.

- Tighten tensioner pulley bolt [11] . Tightening torque: 21±2 Nm.

- Install:

- Reluctor [10] .

- Timing belt lower cover [9] .

- Crankshaft position (CKP) sensor.

- Crankshaft pulley [8] .

- Crankshaft pulley spacer [7] .

- Coat new crankshaft pulley bolt with suitable thread locking compound.

- Fit new crankshaft pulley bolt [6] .

- Tighten crankshaft pulley bolt [6] . Tightening torque: 70 Nm + 60±5°.

- Remove tools [3] , [4] & [5] .

- Turn crankshaft four turns clockwise.

- Install:

- Camshaft sprocket locking tool [3] .

- Flywheel timing pin [4] .

- Ensure tensioner pulley pointer aligned with notch [18] & [19] .

- Remove tools [3] & [4] .

- Install components in reverse order of removal.