Replacement Interval Guide

- Peugeot recommend:

- 206:

- Replacement every 96,000 miles or 10 years under normal conditions.

- Replacement every 80,000 miles or 10 years under adverse conditions.

- 306:

- Replacement every 96,000 miles or 5 years under normal conditions.

- Replacement every 80,000 miles or 5 years under adverse conditions.

- 307:

- Replacement every 96,000 miles or 10 years under normal conditions.

- Replacement every 72,000 miles or 10 years under adverse conditions.

- 406:

- Replacement every 96,000 miles or 10 years under normal conditions.

- Replacement every 72,000 miles or 5 years under adverse conditions.

- 806:

- Replacement every 72,000 miles or 5 years under normal conditions.

- Replacement every 60,000 miles or 5 years under adverse conditions.

- Expert:

- Replacement every 96,000 miles or 10 years under normal conditions.

- Replacement every 72,000 miles or 5 years under adverse conditions.

- The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston damage in the event of a timing belt failure is MOST LIKELY to occur. A compression check of all cylinders should be performed before removing the cylinder head(s).

Repair Times – hrs

| Remove & install: | |

|---|---|

| 206/307 | 3,30 |

| 306 | 3,80 |

| 406 | 4,40 |

| 806 | 4,50 |

| Expert | 4,50 |

Special Tools

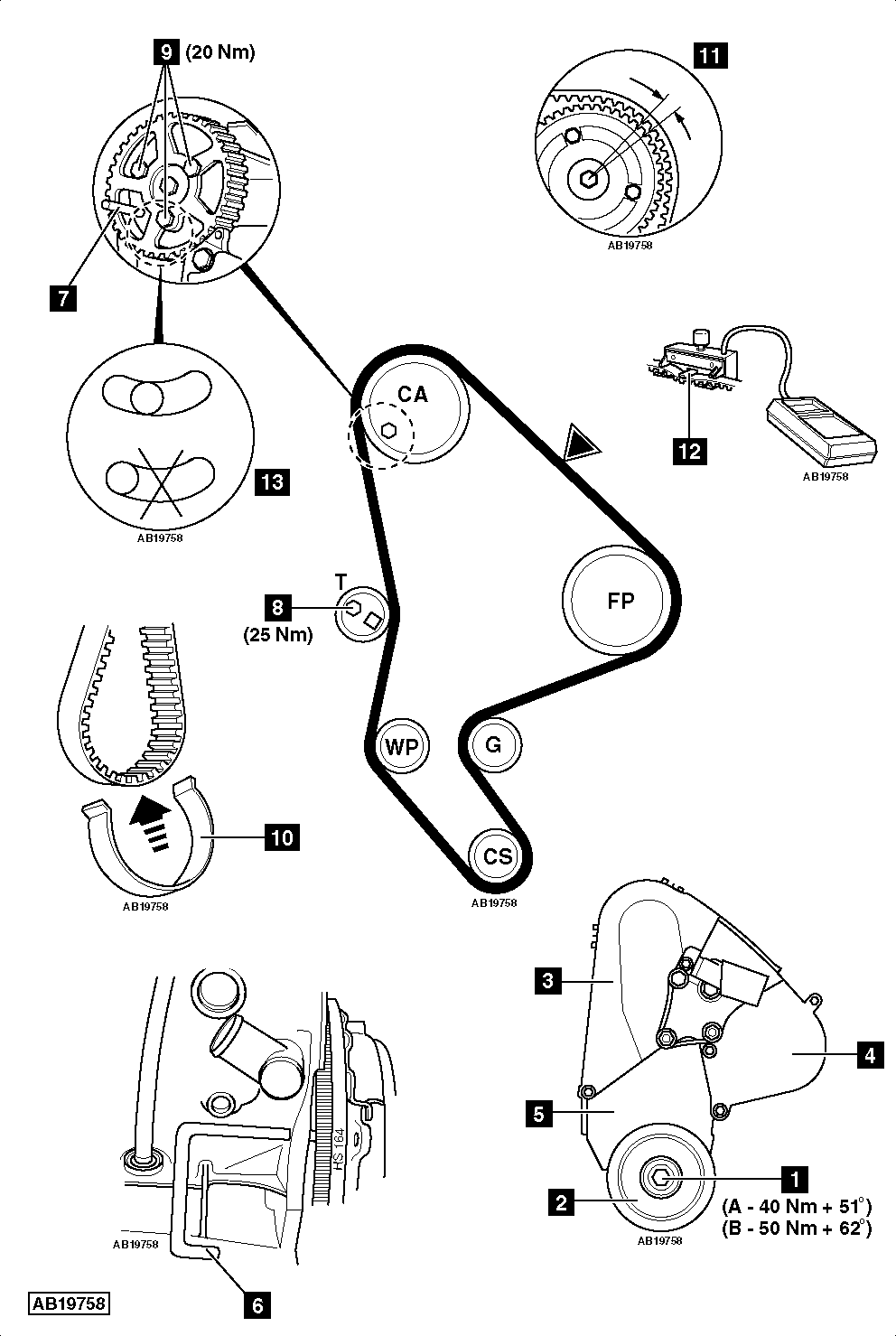

- Flywheel locking tool – Peugeot No.(-).0188-F.

- Crankshaft pulley puller – Peugeot No.(-).0188-P2.

- Flywheel timing pin – Peugeot No.(-).0188-Y.

- Camshaft timing pin – Peugeot No.(-).0188-M.

- Timing belt retaining clip – Peugeot No.(-).0188-K.

- Tensioning tool – Peugeot No.(-).0188-J2.

- Tension gauge – SEEM C.Tronic 105.5.

- Set of blanking plugs – Peugeot No.(-).0188-T.

Special Precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Removal

NOTE: The high-pressure fuel pump fitted to this engine does not require timing.

- Raise and support front of vehicle.

- Disconnect exhaust front pipe from manifold.

- Remove:

- RH front wheel.

- RH splash guard.

- Engine upper cover.

- Auxiliary drive belt.

- Turbocharger air hoses.

- Flywheel housing lower cover.

- Lock flywheel. Use tool No.(-).0188-F.

- Remove:

- Emission filter from pre-catalytic converter (if fitted).

- Crankshaft pulley bolt [1] .

- Crankshaft pulley [2] . Use tool No.(-).0188-P2.

- Flywheel locking tool.

- Lower torque reaction link.

- Reposition:

- Except 307/Expert: Coolant expansion tank. DO NOT disconnect hoses.

- Except 307/Expert: Engine control module (ECM) and tray (leave harness multi-plug connected).

- Expert: Wiring harness and PAS reservoir.

- Disconnect and seal off fuel pipes. Use tool No.(-).0188-T.

- Support engine.

- Remove:

- RH engine mounting and bracket.

- Timing belt covers [3] , [4] & [5] .

- Turn crankshaft clockwise to setting position.

- Insert timing pin in flywheel [6] . Tool No.(-).0188-Y.

- Insert timing pin in camshaft sprocket [7] . Tool No.(-).0188-M.

- Slacken tensioner bolt [8] .

- Turn tensioner pulley clockwise away from belt. Use tool No.(-).0188-J2.

- Lightly tighten tensioner bolt [8] .

- Remove timing belt.

Installation

- Check tensioner pulley and guide pulley for smooth operation.

- Ensure timing pins located correctly [6] & [7] .

- Slacken camshaft sprocket bolts [9] . Tighten bolts finger tight, then slacken 1/6 turn.

- Turn camshaft sprocket fully clockwise in slotted holes.

NOTE: Sprocket should turn with slight resistance.

- Fit timing belt to crankshaft sprocket.

- Secure belt to crankshaft sprocket with retaining clip. Tool No.(-).0188-K [10] .

- Fit timing belt in anti-clockwise direction. Ensure belt is taut between sprockets.

- Lay belt on camshaft sprocket teeth. Engage belt teeth by turning sprocket slightly anti-clockwise.

NOTE: Angular movement of sprocket must not be more than one tooth space [11] .

- Fit timing belt to water pump sprocket and tensioner pulley.

- Slacken tensioner bolt [8] .

- Turn tensioner pulley anti-clockwise to temporarily tension belt. Use tool No.(-).0188-J2.

- Lightly tighten tensioner bolt [8] . Tightening torque: 10 Nm.

- Remove retaining clip [10] .

- Attach tension gauge to belt at

[12] . Tool No.SEEM C-Tronic 105.5.

[12] . Tool No.SEEM C-Tronic 105.5. - Turn tensioner pulley anti-clockwise until tension gauge indicates 98±2 SEEM units.

- Tighten tensioner bolt [8] . Tightening torque: 25 Nm.

- Remove tension gauge [12] .

- Ensure sprocket bolts not at end of slotted holes [13] .

- If necessary: Repeat installation procedure.

- Tighten camshaft sprocket bolts [9] . Tightening torque: 20 Nm.

- Remove timing pins [6] & [7] .

- Turn crankshaft eight turns clockwise to setting position.

NOTE: DO NOT allow crankshaft to turn anti-clockwise.

- Insert timing pins [6] & [7] .

- Slacken camshaft sprocket bolts [9] . Tighten bolts finger tight, then slacken 1/6 turn.

- Slacken tensioner bolt to release tension on belt [8] .

- Attach tension gauge to belt at

[12] .

[12] . - Turn tensioner pulley anti-clockwise until tension gauge indicates 54±2 SEEM units.

- Hold tensioner pulley in position. Tighten tensioner bolt [8] . Tightening torque: 25 Nm.

- Tighten camshaft sprocket bolts [9] . Tightening torque: 20 Nm.

- Remove tension gauge [12] .

- Check belt tension. Attach tension gauge to belt at

[12] . Tension gauge should indicate 51-57 SEEM units.

[12] . Tension gauge should indicate 51-57 SEEM units. - If not: Repeat tensioning procedure.

- Remove tension gauge [12] .

- Remove timing pins [6] & [7] .

- Turn crankshaft two turns clockwise to setting position.

- Insert timing pins [6] & [7] .

NOTE: Ensure timing pins can be inserted easily.

- Remove timing pins [6] & [7] .

- Install components in reverse order of removal.

- Clean crankshaft pulley bolt and crankshaft threads.

- Coat crankshaft pulley bolt with suitable thread locking compound.

- Tighten crankshaft pulley bolt [1] :

- 206/306/307 DW10TD: Tightening torque: 40 Nm + 51°. Check torque setting of crankshaft pulley bolt is 195 Nm.

- 307 DW10ATED/406/806/Expert: Tightening torque: 50 Nm + 62°. Check torque setting of crankshaft pulley bolt is 145 Nm.