-Crankshaft pulley with centre bolt.

Replacement Interval Guide

- Peugeot recommend:

- 206/CC/GTi/406/806:

- Replacement every 80,000 miles or 10 years under normal conditions.

- Replacement every 48,000 miles or 5 years under adverse conditions.

- 206 180/RC:

- Replacement every 72,000 miles or 10 years under normal conditions.

- Replacement every 60,000 miles or 10 years under adverse conditions.

- The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston damage in the event of a timing belt failure is MOST LIKELY to occur. A compression check of all cylinders should be performed before removing the cylinder head(s).

Repair Times – hrs

| Remove & install: | |

|---|---|

| 206/CC/GTi | 3,90 |

| 206 180/RC | 4,40 |

| 406 | 2,20 |

| 806 | 2,10 |

| AC | +0,10 |

Special Tools

- Camshaft timing pins – No.(-).0189-A.

- Flywheel/drive plate locking tool – No.(-).0189-R.

- Timing belt retaining clip – No.(-).0189-K.

- Tensioner pulley adjusting tool – No.(-).0189-S1.

- Tensioner pulley locking tool – No.(-).0189-S2.

Special Precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Removal

- Raise and support front of vehicle.

- Remove:

-

- RH front wheel.

-

- RH splash guard.

-

- 806: Upper torque reaction link (if necessary).

-

- Auxiliary drive belt.

-

- 206: Battery and battery tray.

-

- Disconnect lower torque reaction link.

- 206/406: Remove engine control module (ECM) and bracket.

- 206: Support engine.

- 206: Remove RH engine mounting.

- 206: Disconnect gearbox upper mounting.

- 206: Move engine to the left.

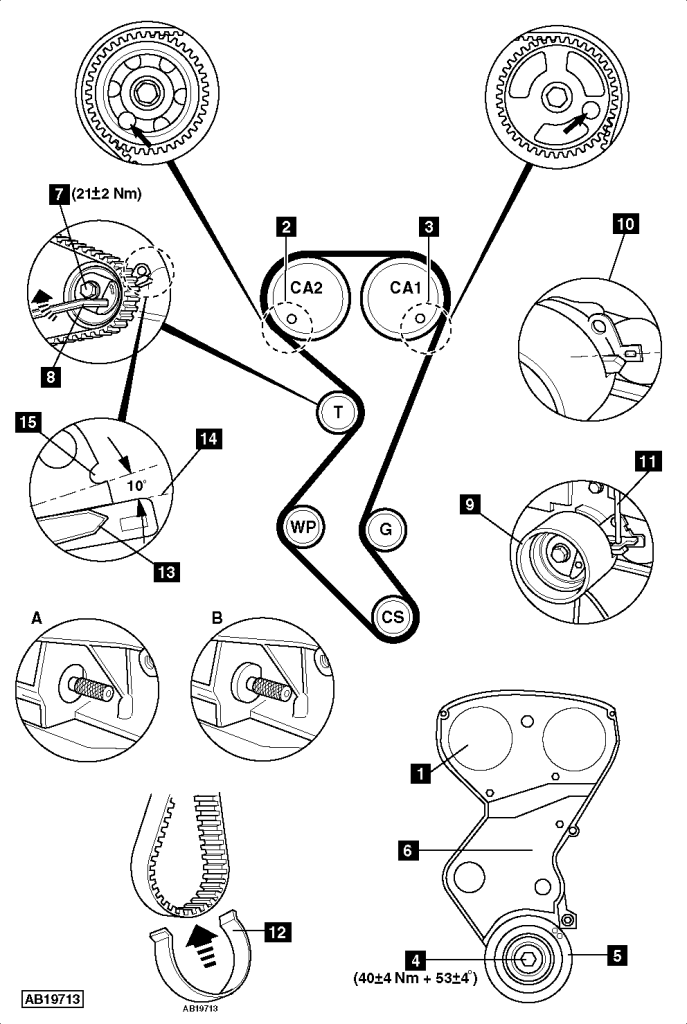

- Remove timing belt upper cover [1] .

- Turn crankshaft clockwise to setting position.

- Insert flywheel/drive plate locking tool. Tool No.(-).0189-R:

-

- [A] : MT.

-

- [B] : AT.

NOTE: Vehicles with AT: Drive plate locking tool will not fit flush in housing.

-

- Insert timing pins in camshaft sprockets [2] & [3] . Tool No.(-).0189-A.

- Remove:

-

- Crankshaft pulley bolt [4] .

-

- Crankshaft pulley [5] .

-

- Timing belt lower cover [6] .

NOTE: Always have tools [A] or [B] , [2] & [3] inserted before removing crankshaft pulley [5] .

-

- Slacken tensioner pulley bolt [7] .

- Turn tensioner pulley clockwise. Use Allen key [8] .

- Remove timing belt.NOTE: Timing belt must always be renewed once it has been removed.

Installation

NOTE: Belt adjustment must be carried out when engine is cold.

- Check tensioner pulley, water pump sprocket and guide pulley for smooth operation. Replace if necessary.

- Ensure flywheel/drive plate locking tool located correctly [A] or [B] .

- Ensure timing pins located correctly [2] & [3] .

- Fit adjusting tool to tensioner pulley [9] . Tool No.(-).0189-S1.

- Turn tensioner pulley clockwise until pointer past notch [10] .

- Fit locking tool to tensioner pulley [11] . Tool No.(-).0189-S2.

- Remove adjusting tool from tensioner pulley [9] .

- Fit timing belt to crankshaft sprocket.

- Secure belt to crankshaft sprocket with retaining clip. Tool No.(-).0189-K [12] .

- Fit timing belt in following order:

-

- Guide pulley.

-

- Inlet camshaft sprocket (CA1).

-

- Exhaust camshaft sprocket (CA2).

-

- Water pump sprocket.

-

- Tensioner pulley.

NOTE: Ensure timing belt is fitted flush with sprockets and pulleys.

-

- Remove tools [12] , [2] & [11] .

- Fit timing belt lower cover [6] .

- Fit crankshaft pulley [5] .

- Tighten crankshaft pulley bolt [4] .

-

- Tightening torque: 40±4 Nm.

-

- Angular tightening torque: 53±4°.

-

- Turn tensioner pulley anti-clockwise until pointer [13] at position [14] . Use Allen key [8] .NOTE: The arrow should pass notch [15] by at least 10°. If not, replace tensioner pulley.

- Turn tensioner pulley clockwise until pointer and notch aligned [13] & [15] .NOTE: If pointer passes notch [15] , repeat tensioning procedure.

- Tighten tensioner pulley bolt to 21±2 Nm [7] .WARNING: Hold tensioner pulley during tightening to prevent it from turning. Allen key socket must be approximately 15° below cylinder head gasket level. If not, replace tensioner pulley.

- Remove tools [A] or [B] & [3] .

- Turn crankshaft 10 turns clockwise to setting position.

- Insert timing pin in inlet camshaft sprocket [3] .

- Ensure tensioner pointer and notch aligned [13] & [15] .NOTE: If pointer passes notch [15] , repeat tensioning procedure.

- Remove timing pin from inlet camshaft sprocket [3] .

- Install components in reverse order of removal.