Special tools

- Camshaft alignment tool – No.T10171A.

- Camshaft sprocket holding tool – No.T10172.

- Crankshaft pulley holding tool 1 – No.3415.

- Crankshaft pulley holding tool 2 – No.3415/1.

- Crankshaft timing pin – No.T10340.

- Dial gauge – No.VAS 6079.

- Dial gauge holder – No.T10170.

- Tensioner locking tool – No.T40011.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

- Removal/installation of timing chain requires:

- Timing chain cover removal.

- Sump removal.

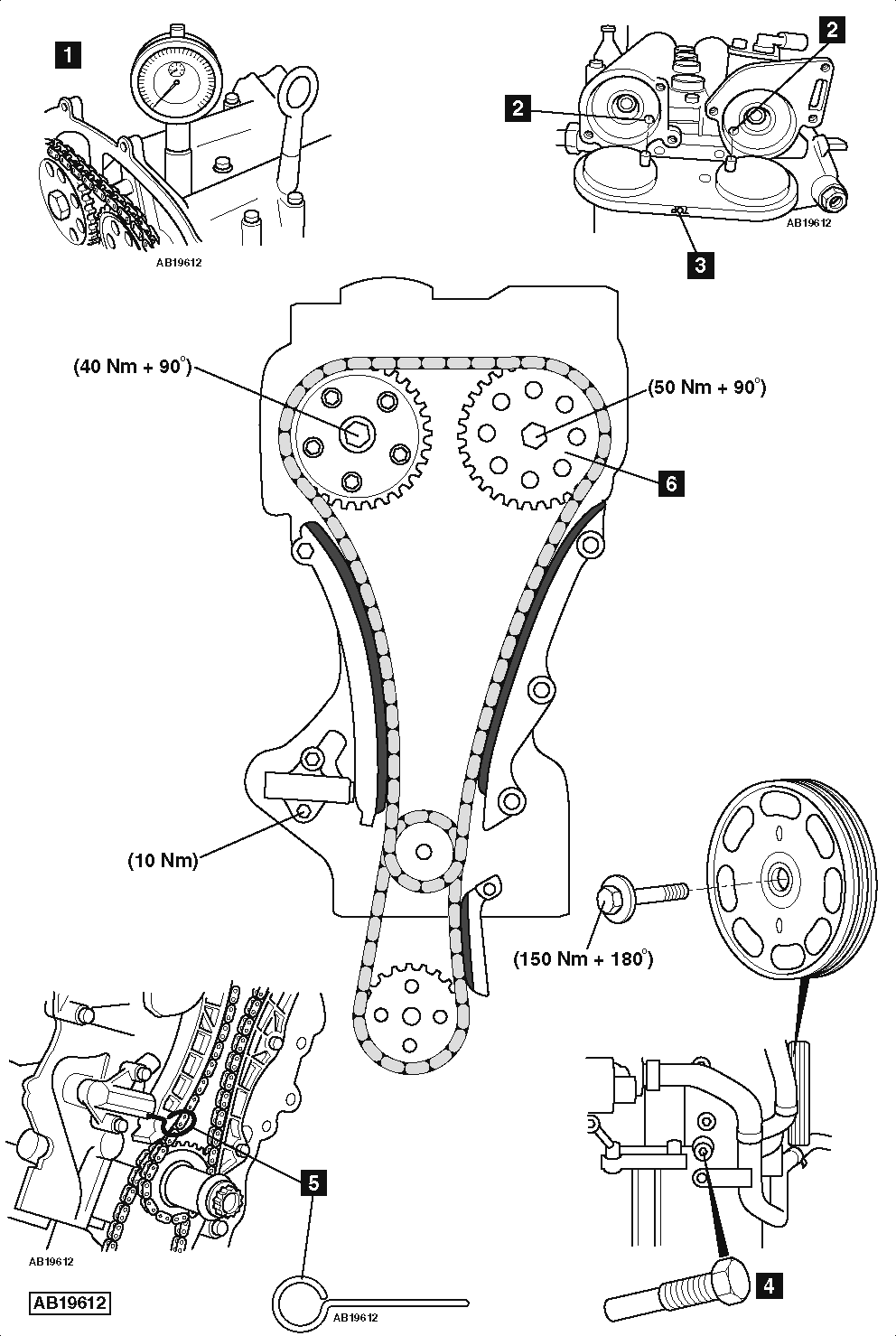

- Install dial gauge and holder in No.1 cylinder plug hole. Ensure engine at TDC on No.1 cylinder [1] .

- Ensure timing marks on camshafts aligned as shown [2] . If not, turn crankshaft 360°.

- Fit camshaft alignment tool [3] .

NOTE: If camshaft alignment tool cannot be inserted valve timing is incorrect.

- Install crankshaft timing pin [4] .

- Refit crankshaft pulley bolt with spacer. Finger tighten bolt.

- Push tensioner rail against chain tensioner.

- Fit tensioner locking tool [5] .

NOTE: If reusing timing chain: Mark direction of rotation on chains.

- Remove camshaft alignment tool [3] .

- Slacken bolt of each camshaft sprocket.

NOTE: Inlet camshaft sprocket bolt has LH thread.

- Remove exhaust camshaft sprocket [6] and timing chain.

- Align camshafts. Use special tool [3] .

- Ensure crankshaft at TDC on No.1 cylinder:

- Turn crankshaft slowly clockwise until it stops against timing pin [4] .

- Install exhaust camshaft sprocket [6] with timing chain.

- Renew bolt of each camshaft sprocket and re-tighten by hand.

- Ensure camshaft sprockets turn freely but do not tilt.

- Remove tensioner locking tool [5] .

- Ensure crankshaft at TDC on No.1 cylinder:

- Turn crankshaft slowly clockwise until it stops against timing pin.

- Ensure camshaft alignment tool correctly located [3] .

- Temporarily tighten camshaft sprocket bolts to:

- Inlet camshaft sprocket bolt. Tightening torque: 40 Nm.

- Exhaust camshaft sprocket bolt. Tightening torque: 50 Nm.

- Remove camshaft alignment tool [3] .

- Remove crankshaft timing pin [4] .

- Turn crankshaft two turns clockwise.

- Check engine at TDC on No.1 cylinder. Use dial gauge [1] .

- Fit crankshaft timing pin [4] .

- Ensure camshaft alignment tool can be fitted [3] .

- If camshaft alignment tool cannot be fitted valve timing is incorrect. Repeat installation procedures.

- Remove camshaft alignment tool [3] .

- Remove crankshaft timing pin [4] .

- Tighten camshaft sprocket bolts a further 90°.

- Turn crankshaft two turns clockwise.

- Check valve timing.

- Tighten crankshaft pulley bolt. Tightening torque: 150 Nm + 180°.

NOTE: Crankshaft pulley bolt and bolt on each camshaft sprocket MUST only be used once.