Special tools

- Camshaft alignment tools – No.303-1445.

- Camshaft turning tools – No.303-1452.

- Crankshaft pulley bolt socket – No.303-1438.

- Crankshaft pulley holding tool – No.303-1437.

- Crankshaft pulley removal/installation tool 1 – No.303-1439.

- Crankshaft pulley removal/installation tool 2 – No.303-1440.

- Crankshaft pulley removal/installation tool 3 – No.303-1441.

- Crankshaft timing pin (crankshaft position (CKP) sensor aperture) – No.303-1447.

- Flywheel/drive plate locking tool (starter motor aperture) – No.303-1448

- Timing chain pre-tensioning tool – No.303-1482.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

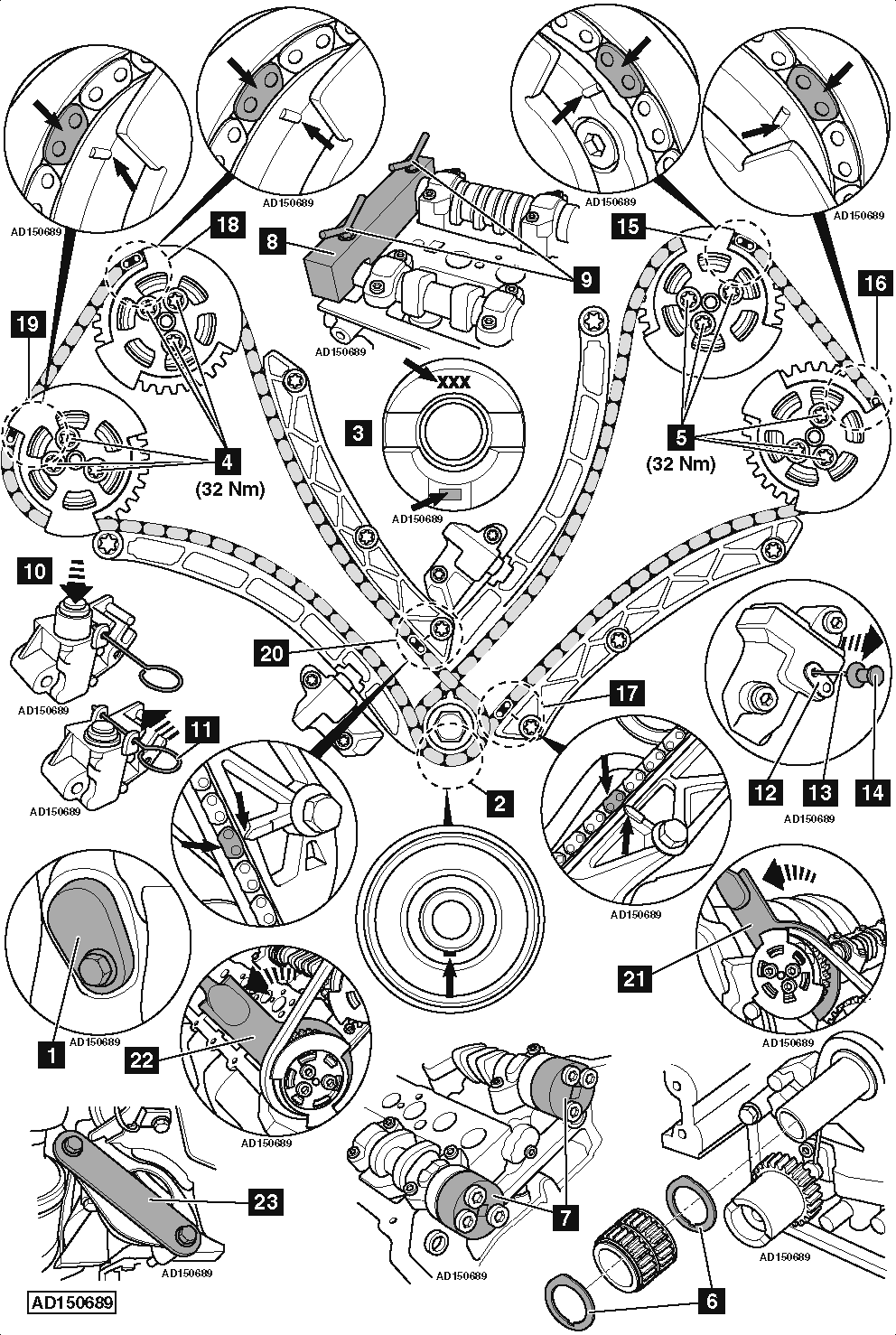

Removal

- Remove crankshaft position (CKP) sensor.

- Turn crankshaft in direction of engine rotation until crankshaft timing pin can be installed [1] .

- Ensure crankshaft sprocket keyway at 6 o’clock position [2] .

NOTE: If crankshaft sprocket keyway at 9 o’clock position, replace drive plate.

- Ensure groove in rear of camshafts positioned as shown [3] .

- Remove RH bank timing chain tensioner and tensioner blade.

- Slacken bolts of each RH bank camshaft adjuster [4] .

- Remove RH bank camshaft adjusters and timing chain.

- Remove LH bank timing chain tensioner and tensioner blade.

- Slacken bolts of each LH bank camshaft adjuster [5] .

- Remove LH bank camshaft adjusters and timing chain.

NOTE: Crankshaft sprocket friction washers MUST be replaced [6] .

Installation

- Ensure crankshaft timing pin correctly fitted [1] .

- Ensure crankshaft sprocket keyway at 6 o’clock position [2] .

- Ensure groove in rear of camshafts positioned as shown [3] .

- Install camshaft turning tools to front of LH bank camshafts [7] .

- Install camshaft alignment tool to rear of LH bank camshafts [8] .

- Ensure camshaft alignment tool engages in end of camshafts. Secure tool with bolts [9] . Finger tighten bolts.

- Rock camshafts slightly to ensure camshaft alignment tool located correctly.

- Remove camshaft turning tools [7] .

- Install camshaft turning tools to front of RH bank camshafts [7] .

- Install camshaft alignment tool to rear of RH bank camshafts [8] .

- Ensure camshaft alignment tool engages in end of camshafts. Secure tool with bolts [9] . Finger tighten bolts.

- Rock camshafts slightly to ensure camshaft alignment tool located correctly.

- Lock LH and RH bank timing chain tensioners in retracted position:

NOTE: There are two types of tensioner.

- Tensioner – type A:

- Push plunger into tensioner body in direction of arrow [10] .

- Insert a suitable pin into tensioner body to lock tensioner plunger in position [11] .

- Tensioner – type B:

- Turn tensioner pawl fully clockwise [12] .

- Push plunger into tensioner body in direction of arrow [13] .

- Turn tensioner pawl fully anti-clockwise [12] .

- Insert a suitable pin into tensioner body to lock tensioner plunger in position [14] .

- Install LH bank camshaft adjusters and timing chain as an assembly. Finger tighten bolts.

- Ensure coloured or painted chain links aligned with timing marks on each camshaft adjuster and chain guide [15] , [16] & [17] .

- Install LH bank timing chain tensioner and tensioner blade.

- Install RH bank camshaft adjusters and timing chain as an assembly. Finger tighten bolts.

- Ensure coloured or painted chain links aligned with timing marks on each camshaft adjuster and chain guide [18] , [19] & [20] .

- Install RH bank timing chain tensioner and tensioner blade.

- Remove pin to release timing chain tensioner plunger [11] & [14] .

- Install timing chain pre-tensioning tool to LH bank inlet camshaft adjuster [21] .

- Apply a pre-tensioning torque of 35 Nm.

- Tighten LH bank exhaust camshaft adjuster bolts. Tightening torque: 32 Nm.

- Tighten LH bank inlet camshaft adjuster bolts. Tightening torque: 32 Nm.

- Remove timing chain pre-tensioning tool [21] .

- Install timing chain pre-tensioning tool to RH bank exhaust camshaft adjuster [22] .

- Apply a pre-tensioning torque of 35 Nm.

- Tighten RH bank inlet camshaft adjuster bolts. Tightening torque: 32 Nm.

- Tighten RH bank exhaust camshaft adjuster bolts. Tightening torque: 32 Nm.

- Remove timing chain pre-tensioning tool [22] .

- Remove camshaft alignment tools [8] .

- Remove crankshaft timing pin [1] .

- Fit flywheel/drive plate locking tool [23] .

- Temporarily fit crankshaft pulley bolt with M16 washer. Tightening torque: 50 Nm.

- Remove flywheel/drive plate locking tool [23] .

- Turn crankshaft two turns clockwise.

- Fit flywheel/drive plate locking tool [23] .

- Remove crankshaft pulley bolt.

- Remove flywheel/drive plate locking tool [23] .

- Turn crankshaft in direction of engine rotation until crankshaft timing pin can be installed [1] .

- Ensure camshaft alignment tools can be fitted [8] . If not, repeat timing chain installation.

- Remove camshaft alignment tools [8] .

- Remove crankshaft timing pin [1] .

- There are two types of crankshaft pulley bolt:

- Bolt classification – 10.9 (RH thread).

- Bolt classification – 12.9 (LH thread).

- Tighten crankshaft pulley bolt. Use new bolt. Tightening torque: 200 Nm + 270°.