Skip to content

Special tools

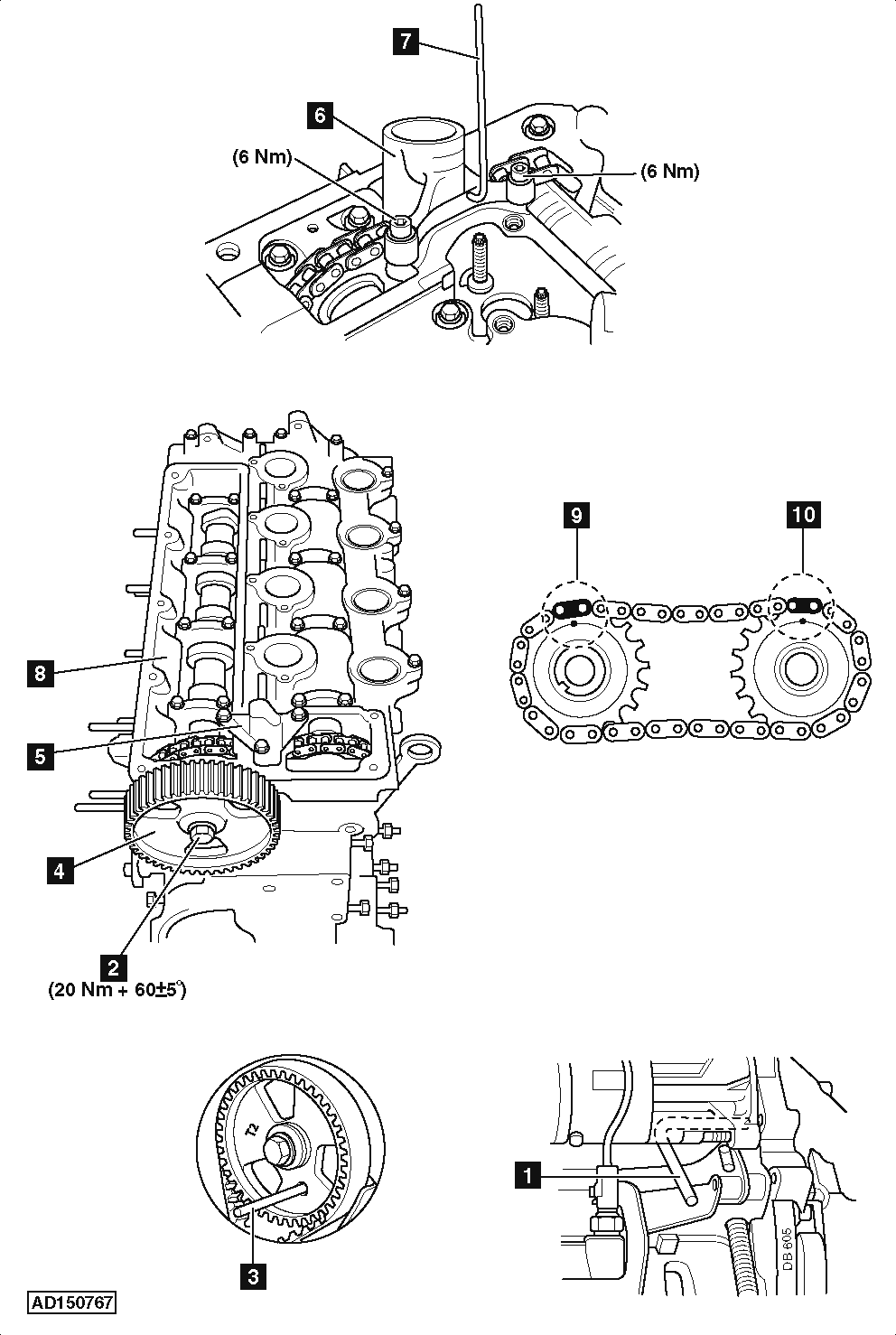

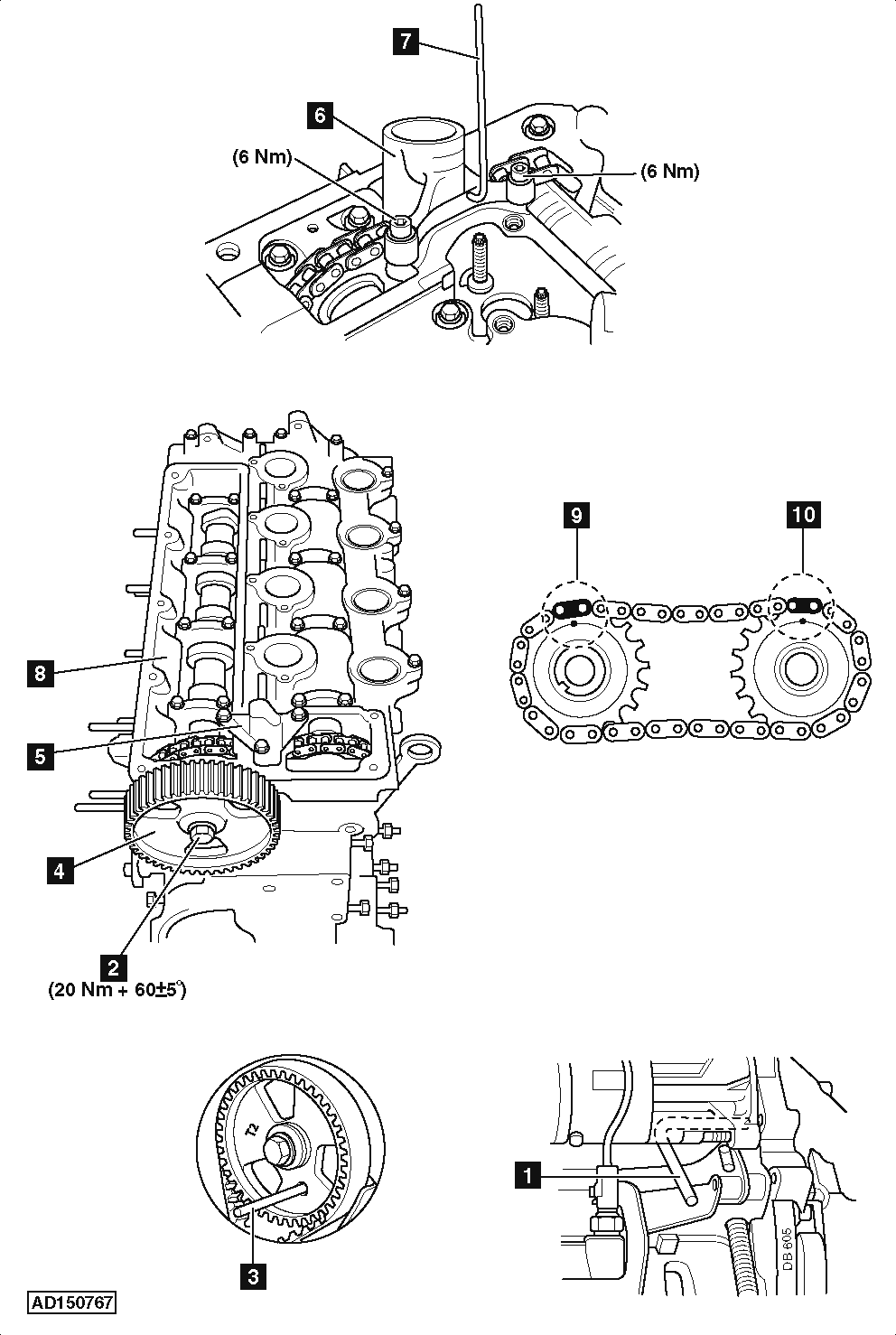

- Camshaft sprocket holding tool – No.(-).0132.AA.

- Camshaft timing pin – No.(-).0188.M.

- Flywheel locking tool – No.(-).0188.F.

- Flywheel timing pin – No.(-).0188.X/Y.

- Tensioner locking tool – No.(-).0188.Q2.

General precautions

- Disconnect battery earth lead.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

Removal

- Removal/installation of timing chain requires:

- Ensure flywheel timing pin located correctly [1] .

- Slacken camshaft sprocket bolt [2] . Hold camshaft sprocket with holding tool.

- Remove camshaft timing pin [3] .

- Remove camshaft sprocket [4] .

- Lock timing chain tensioner in retracted position [5] :

- Push plunger into tensioner housing [6] .

- Insert 2,0 mm pin to lock tensioner plunger [7] .

- Remove timing chain tensioner [5] .

- Remove camshaft housing [8] .

- Remove timing chain and camshafts as an assembly.

Installation

- Remove flywheel timing pin [1] .

- Turn crankshaft anti-clockwise 90° until crankshaft keyway at 9 o’clock position.

- Align coloured chain links with timing mark on each sprocket [9] & [10] .

- Install timing chain and camshafts as an assembly.

- Install camshaft housing [8] .

- Install timing chain tensioner [5] .

- Remove pin to release timing chain tensioner plunger [6] .

- Install camshaft sprocket [4] .

- Fit camshaft timing pin [3] .

- Turn crankshaft clockwise 90° until crankshaft keyway at 12 o’clock position.

- Fit flywheel timing pin [1] .

- Install timing belt.