Manufacturer: Dacia

Engine code: K9K 892

Tuned for:

Model: Duster (10-) 1,5D dCi Output: 66 (90) 3750 Year: 2010-14

| Remove & install: | |

| Duster | 2,00 |

| Logan/Sandero | 2,00 |

| AC | +0,10 |

| PAS_ | +0,10 |

Special Tools

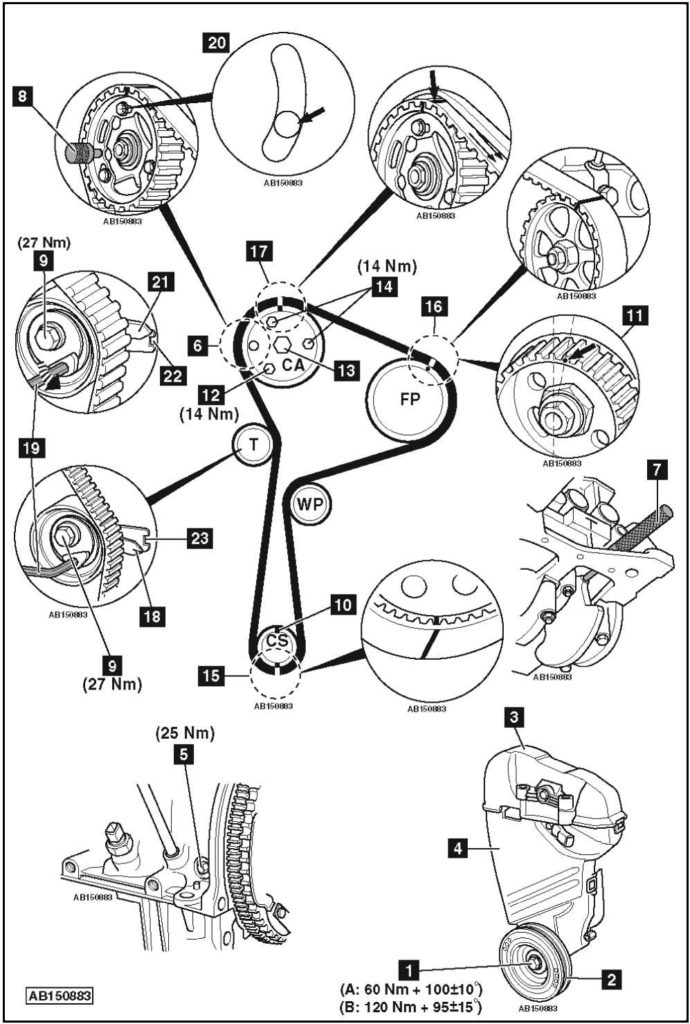

• Camshaft timing pin – No.Mot.1430.

• Crankshaft timing pin – No.Mot.1489.

Special Precautions

• Disconnect battery earth lead.

• DO NOT turn crankshaft or camshaft when timing belt removed.

• Remove glow plugs to ease turning engine.

• Turn engine in normal direction of rotation (unless otherwise stated).

• DO NOT turn engine via camshaft or other sprockets.

• Observe all tightening torques.

Removal

1. Raise and support front of vehicle.

2. Remove:

- Camshaft position (CMP) sensor.

- RH front wheel.

- RH wheel arch liner.

- Engine undershield.

- Auxiliary drive belt.

NOTE: Auxiliary drive belt(s), tensioner pulley and guide pulley(s) MUST be replaced.

3. Lock flywheel with large screwdriver. Slacken crankshaft pulley bolt [1] .

4. Remove:

- Crankshaft pulley bolt [1] .

- Crankshaft pulley [2] .

5. Disconnect and seal off fuel pipes.

6. Support engine.

7. Remove RH engine mounting.

NOTE: Mark position of RH engine mounting before removal.

8. Remove:

- Timing belt upper cover [3] .

- Timing belt lower cover [4] .

- RH engine mounting bracket.

- Blanking plug from cylinder block [5] .

9. Refit crankshaft pulley bolt with spacer [1] .

10. Turn crankshaft clockwise until camshaft sprocket timing pin locating hole almost aligned with hole in cylinder head [6] .

11. Insert crankshaft timing pin [7] . Tool No.Mot.1489.

12. Turn crankshaft slightly until crankshaft web stops against timing pin [7] .

13. Insert camshaft timing pin [8] . Tool No.Mot.1430.

14. Slacken tensioner pulley bolt [9] . Move tensioner away from belt.

15. Remove:

- Timing belt.

Installation

NOTE: Timing belt and tensioner pulley MUST be replaced.

1. Fit new tensioner pulley. Finger tighten bolt [9] . Use new bolt. Ensure tensioner pulley retaining lug located correctly in cylinder head.

2. Ensure crankshaft keyway pointing vertically upwards [10] .

3. Ensure high-pressure fuel pump sprocket timing mark aligned as shown [11] .

4. Remove one camshaft sprocket bolt [12] .

NOTE: DO NOT slacken camshaft sprocket hub nut [13] .

5. Slacken two camshaft sprocket bolts one turn [14] .

6. Fit timing belt, starting at crankshaft sprocket. Ensure marks on belt aligned with marks on sprockets [15] , [16] & [17] . Ensure belt is taut on non-tensioned side.

NOTE: There should be 19 troughs between camshaft sprocket and high-pressure fuel pump sprocket timing marks [17] & [16] and 51 troughs between high-pressure fuel pump sprocket and crankshaft sprocket timing marks [16] & [15] .

7. Turn tensioner pulley anti-clockwise until pointer at lower position [18] . Use 6 mm Allen key [19] . Tighten tensioner pulley bolt [9] . Tightening torque: 27 Nm.

8. Ensure camshaft sprocket bolts not at end of slotted holes [20] . If not: Repeat installation procedure.

9. Fit camshaft sprocket bolt [12] .

10. Tighten camshaft sprocket bolts [12] & [14] . Tightening torque: 14 Nm.

11. Remove timing pins [7] & [8] .

12. Turn crankshaft two turns clockwise until camshaft sprocket timing pin locating hole almost aligned with hole in cylinder head [6] .

13. Insert crankshaft timing pin [7] .

14. Turn crankshaft slightly until crankshaft web stops against timing pin [7] .

15. Insert camshaft timing pin [8] .

16. Slacken camshaft sprocket bolts one turn [12] & [14] .

17. If timing pin cannot be inserted:

■ Slacken camshaft sprocket bolts one turn [12] & [14] .

■ Turn camshaft sprocket hub nut [13] until timing pin [8] can be inserted.

■ DO NOT tighten bolts [12] & [14] .

18. Ensure crankshaft sprocket keyway at 12 o’clock position [10] .

19. Ensure high-pressure fuel pump sprocket timing mark aligned as shown [11] .

NOTE: There should be 19 troughs between camshaft sprocket and high-pressure fuel pump sprocket timing marks [17] & [16] and 51 troughs between high-pressure fuel pump sprocket and crankshaft sprocket timing marks [16] & [15] .

NOTE: Tensioner pulley pointer can be in two positions.

20. Tensioner pulley pointer at position shown [21] :

■ Hold tensioner pulley. Use 6 mm Allen key [19] .

■ Slacken tensioner pulley bolt [9] .

■ Turn tensioner pulley anti-clockwise until pointer aligned with notch [21] & [22] . Use 6 mm Allen key [19] .

21. Tensioner pulley pointer at position shown [18] :

■ Hold tensioner pulley. Use 6 mm Allen key [19] .

■ Slacken tensioner pulley bolt [9] .

■ Turn tensioner pulley clockwise until pointer aligned with notch [18] & [23] . Use 6 mm Allen key [19] .

22. Tighten tensioner pulley bolt [9] . Tightening torque: 27 Nm.

23. Tighten camshaft sprocket bolts [12] & [14] . Tightening torque: 14 Nm.

24. Remove timing pins [7] & [8] .

25. Turn crankshaft two turns clockwise until camshaft sprocket timing pin locating hole almost aligned with hole in cylinder head [6] .

26. Insert crankshaft timing pin [7] .

27. Turn crankshaft slightly until crankshaft web stops against timing pin [7] .

28. Insert camshaft timing pin [8] .

29. If timing pin cannot be inserted: Repeat installation procedure.

30. Remove old crankshaft pulley bolt and spacer [1] .

NOTE: DO NOT start engine without auxiliary drive belt fitted as damage may occur to crankshaft pulley.

31. Fit crankshaft pulley [2] .

32. Fit new crankshaft pulley bolt [1] . Tightening torque:

■ A: K9K 790/794 – 60 Nm + 100±10°.

■ B: Except K9K 790/794 – 120 Nm + 95±15°.

33. Remove timing pins [7] & [8] .

34. Apply locking compound to blanking plug [5] .

35. Fit blanking plug [5] . Tightening torque: 25 Nm.