Audio TT 2.0 DTi 2009 cambelt change instructions and replacement inteval. Full guide!

Special tools

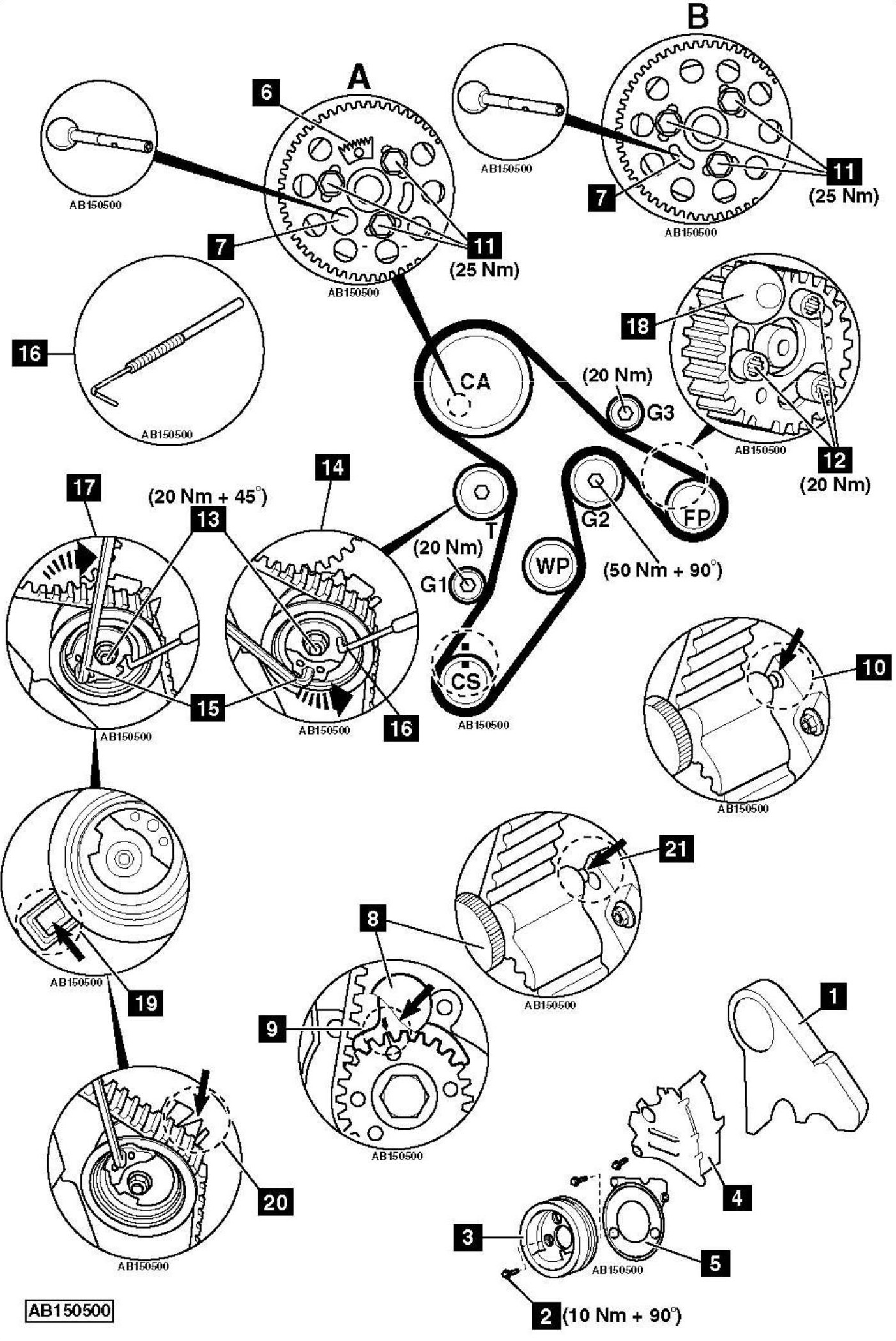

- Auxiliary drive belt tensioner locking pin – No.T10060A.

- Camshaft sprocket/high-pressure fuel pump sprocket holding tool – Nos.T10172/4.

- Camshaft sprocket/high-pressure fuel pump sprocket locking tool – No.3359 (x 2).

- Crankshaft sprocket locking tool – No.T10050.

- Multi-spline socket – No.T10385.

- Tensioner pulley adjusting tool – No.T10264.

- Tensioner pulley locking tool – No.T10265.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 2,20 |

Valve timing procedures

Removal

- Raise and support front of vehicle.

- Remove:

- Engine upper cover.

- RH front wheel.

- Engine undershield.

- RH splash guard.

- A3 Cabrio/TT: Engine undershield mounting bracket.

- Disconnect diesel particulate filter (DPF) pressure sensor multi-plug.

- Reposition:

- A1/A3: Diesel particulate filter (DPF) pressure sensor bracket.

- A3: Windscreen washer reservoir filler neck.

- A3/Q3/TT: Unclip fuel hose from fuel hose support bracket.

- A3/Q3/TT: Reposition fuel hose support bracket.

- A3/Q3/TT: Disconnect fuel lift pump multi-plug.

- A3/Q3/TT: Reposition fuel lift pump support bracket.

- A3/Q3/TT: Reposition fuel filter. DO NOT disconnect fuel pipes.

- Disconnect engine coolant temperature (ECT) sensor multi-plug.

- A1: Move coolant expansion tank to one side. DO NOT disconnect hoses.

- A3/Q3/TT: Reposition coolant hose from timing belt upper cover. DO NOT disconnect hose.

- Support engine.

- Remove:

- RH engine mounting and bracket.

- Timing belt upper cover [1] .

- Auxiliary drive belt. Use tool No.T10060A.

NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

- Crankshaft pulley bolts [2] .

- Crankshaft pulley [3] .

- Timing belt centre cover [4] .

- Timing belt lower cover [5] .

- Turn crankshaft clockwise to TDC on No.1 cylinder.

- Camshaft sprocket – type A: Ensure camshaft sprocket window at approximately 12 o’clock position [6] . If not: Turn crankshaft one turn clockwise.

- Camshaft sprocket – type B: Ensure camshaft sprocket timing hole at 7 o’clock position [7] . If not: Turn crankshaft one turn clockwise.

- Lock camshaft sprocket [7] . Use tool No.3359.

- Lock crankshaft sprocket [8] . Use tool No.T10050.

- Ensure timing marks aligned [9] .

- Ensure lug of crankshaft sprocket locking tool located in oil seal housing [10] .

- Slacken camshaft sprocket bolts [11] .

- Slacken high-pressure fuel pump sprocket bolts [12] . Use tool No.T10385.

NOTE: Sprockets should turn freely but not tilt. - Slacken tensioner pulley nut [13] .

- Turn tensioner pulley anti-clockwise until locking tool can be inserted [14] . Use tool No.T10264 [15] .

- Insert locking tool in tensioner pulley [16] . Tool No.T10265.

- Turn tensioner pulley fully clockwise until it reaches stop [17] . Use tool No.T10264 [15] .

- Tighten tensioner pulley nut finger tight [13] .

- Remove timing belt, starting at guide pulley (G3).

NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

Installation

NOTE: Engine must be COLD.

- Fit new high-pressure fuel pump sprocket bolts [12] . Tighten bolts finger tight.

- Ensure tensioner pulley locking tool inserted [16] .

- Ensure camshaft sprocket locking tool located correctly [7] .

- Ensure crankshaft sprocket locking tool located correctly [10] .

- Ensure timing marks aligned [9] .

- Lock high-pressure fuel pump sprocket [18] . Use tool No.3359.

- If locking tool cannot be inserted [18] : Turn high-pressure fuel pump sprocket as required.

- Turn camshaft sprocket and high-pressure fuel pump sprocket fully clockwise in slotted holes.

- Fit timing belt in following order:

- Crankshaft sprocket.

- Guide pulley (G1).

- Tensioner pulley.

- Camshaft sprocket.

- Water pump sprocket.

- Guide pulley (G3).

- High-pressure fuel pump sprocket.

- Guide pulley (G2).

- Slacken tensioner pulley nut [13] .

- Remove locking tool from tensioner pulley [16] .

- Ensure tensioner pulley retaining lug is properly engaged [19] .

- Turn camshaft sprocket anti-clockwise to remove slack from belt between camshaft sprocket and high-pressure fuel pump sprocket. Use tool Nos.T10172/4.

- Hold camshaft sprocket. Use tool Nos.T10172/4.

- Tighten camshaft sprocket and high-pressure fuel pump sprocket bolts [11] & [12] . Tightening torque: 20 Nm.

- Turn tensioner pulley slowly clockwise until pointer aligned with notch [20] .

NOTE: Ensure tensioner pulley nut does not turn [13] . - Hold tensioner pulley. Use tool No.T10264 [15] .

- Tighten tensioner pulley nut [13] . Tightening torque: 20 Nm + 45°.

- Remove:

- Camshaft sprocket locking tool [7] .

- High-pressure fuel pump sprocket locking tool [18] .

- Crankshaft sprocket locking tool [8] .

- Turn crankshaft slowly two turns clockwise until just before TDC on No.1 cylinder.

- Fit crankshaft sprocket locking tool while slowly turning crankshaft to TDC [8] .

- Ensure lug of crankshaft sprocket locking tool located in oil seal housing [10] .

- Ensure timing marks aligned [9] .

- Ensure camshaft sprocket locking tool can be inserted easily [7] .

NOTE: DO NOT insert high-pressure fuel pump sprocket locking tool as alignment hole may be slightly misaligned. No adjustment required. - Ensure tensioner pulley pointer aligned with notch or 5 mm maximum to the right of notch [20] . If not: Repeat installation procedure.

- If camshaft sprocket locking tool cannot be inserted easily [7] :

- Remove lug of crankshaft sprocket locking tool from hole in oil seal housing.

- Turn crankshaft anti-clockwise until lug of locking tool just passes hole in oil seal housing [21] .

- Turn crankshaft clockwise until camshaft locking tool can be inserted [7] .

- Slacken camshaft sprocket bolts [11] .

NOTE: Lug of crankshaft sprocket locking tool will be positioned to the left or right of hole in oil seal housing.

- If lug of crankshaft sprocket locking tool is positioned to the left of hole in oil seal housing:

- Turn crankshaft clockwise until lug and hole aligned [10] .

- Lock crankshaft sprocket [8] .

- Ensure timing marks aligned [9] .

- Hold camshaft sprocket. Use tool Nos.T10172/4.

- Tighten camshaft sprocket bolts [11] . Tightening torque: 20 Nm.

- If lug of crankshaft sprocket locking tool is positioned to the right of hole in oil seal housing:

- Turn crankshaft anti-clockwise until lug of locking tool just passes hole in oil seal housing [21] .

- Turn crankshaft clockwise until lug and hole aligned [10] .

- Lock crankshaft sprocket [8] .

- Ensure timing marks aligned [9] .

- Hold camshaft sprocket. Use tool Nos.T10172/4.

- Tighten camshaft sprocket bolts [11] . Tightening torque: 20 Nm.

- Remove:

- Camshaft sprocket locking tool [7] .

- Crankshaft sprocket locking tool [8] .

- Turn crankshaft slowly two turns clockwise until just before TDC on No.1 cylinder.

- Ensure locking tools can be inserted [8] & [7] .

- Ensure timing marks aligned [9] .

- Hold camshaft sprocket. Use tool Nos.T10172/4.

- Tighten camshaft sprocket bolts [11] . Tightening torque: 25 Nm.

- Turn crankshaft slowly two turns clockwise until just before TDC on No.1 cylinder.

- Ensure locking tools can be inserted [8] & [7] .

- Ensure timing marks aligned [9] .

- Remove locking tools [8] & [7] .

- Install components in reverse order of removal.

- Tighten crankshaft pulley bolts [2] . Tightening torque: 10 Nm + 90°. Use new bolts.