Skip to content

Special tools

- Camshaft alignment tool 1 – No.EN-48383-1.

- Camshaft alignment tool 2 – No.EN-48383-2.

- Camshaft alignment tool 3 – No.EN-48383-3.

- Crankshaft alignment/turning tool – No.EN-48589.

- Crankshaft pulley holding tool – No.EN-47981.

- Crankshaft pulley holding tool handle – No.EN-956-1.

- Crankshaft pulley installer – No.EN-41998-B.

- Crankshaft pulley removal tool – No.EN-47982.

- Flywheel/drive plate locking tool – No.EN-46106.

- Tensioner locking pin – No.EN-46112.

- Tensioner plunger resetting tool – No.EN-49416.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

How to replace timing chain on Vauxhall/Opel Insignia 2.8 Turbo 4×4

How to replace timing chain on Vauxhall/Opel Insignia 2.8 Turbo 4×4

Valve timing procedures

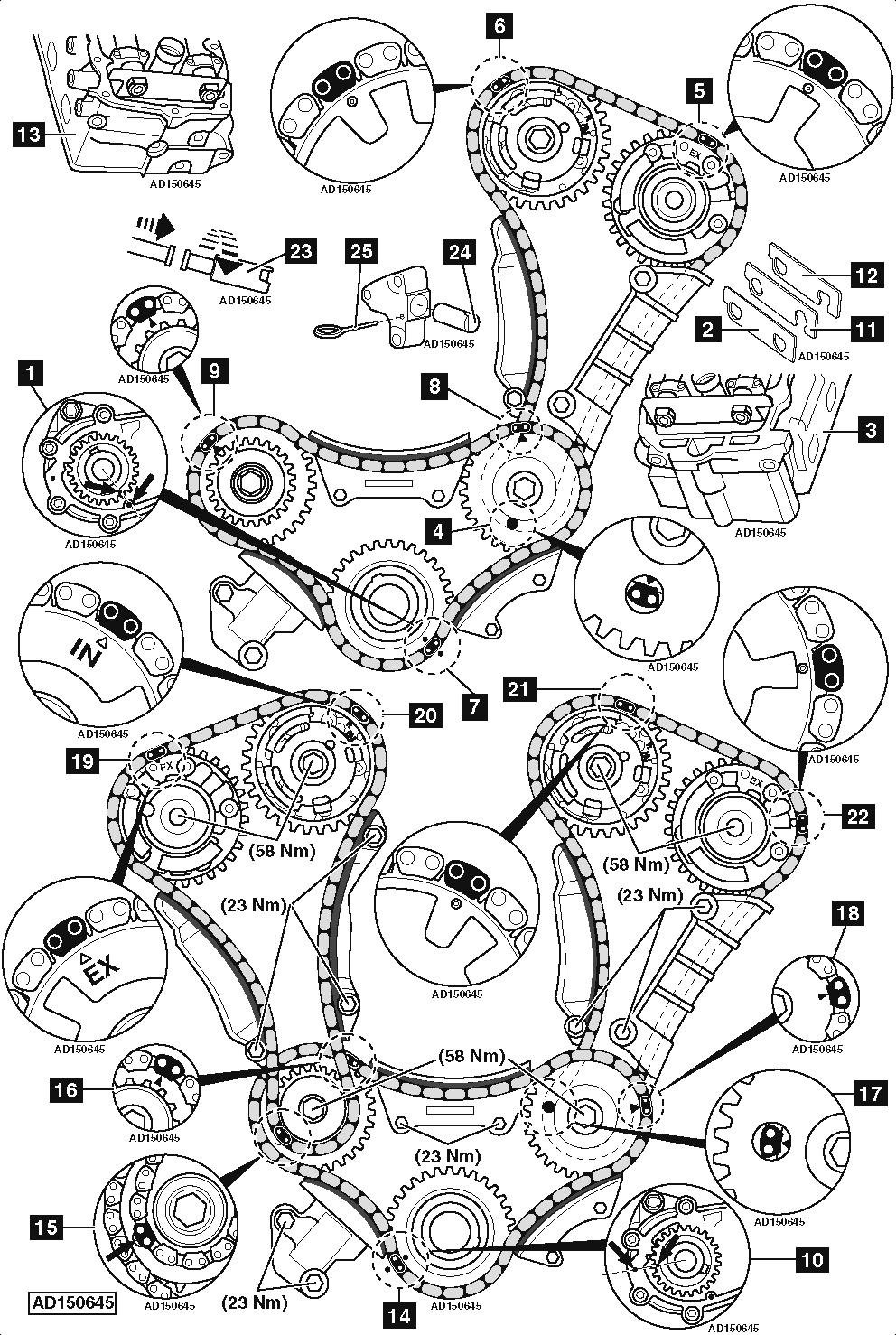

- Stage 1 alignment position (LH bank):

- Using crankshaft alignment/turning tool, rotate the crankshaft clockwise to the stage 1 alignment position [1] .

- Install camshaft alignment tool 1 to rear of LH camshafts [2] & [3] .

- Ensure LH secondary timing chain coloured chain links aligned with timing mark on each sprocket [4] , [5] & [6] .

- Ensure there are 10 chain links located between the timing marks on both camshaft sprockets [5] & [6] .

- Ensure there are 22 chain links located between the timing marks on both camshaft sprockets [4] & [5] .

- Ensure there are 22 chain links located between the timing marks on both camshaft sprockets [4] & [6] .

- Ensure primary timing chain coloured chain links aligned with timing mark on each sprocket [7] , [8] & [9] .

- Remove camshaft alignment tool 1.

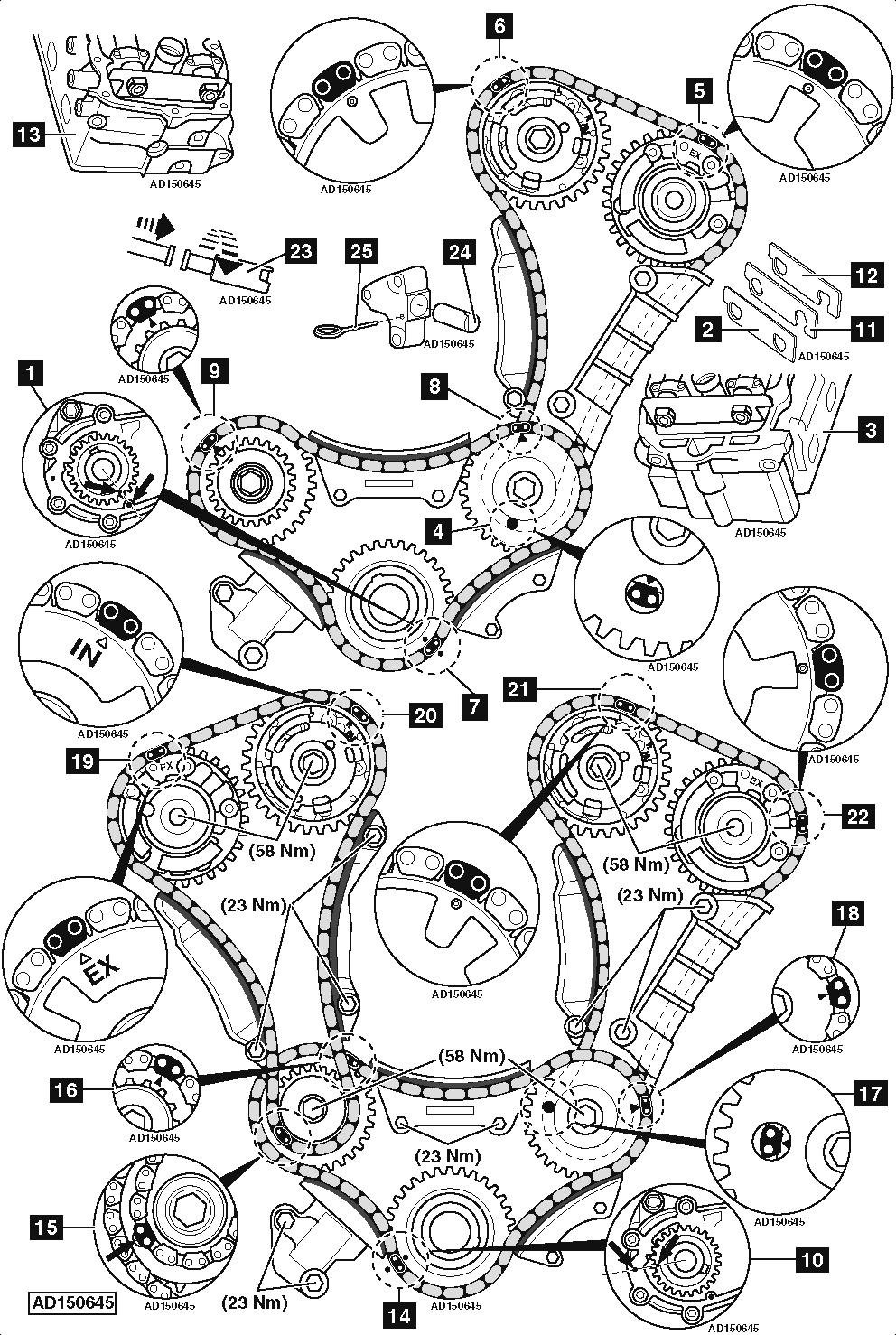

- Stage 2 alignment position (RH bank):

- Using crankshaft alignment/turning tool, rotate the crankshaft 115° clockwise to the stage 2 alignment position [10] .

- Install camshaft alignment tool 2 to rear of LH camshafts [11] & [3] .

- Install camshaft alignment tool 3 to rear of RH camshafts [12] & [13] .

- Ensure coloured chain links aligned with timing marks on sprockets [14] , [15] , [16] , [17] , [18] , [19] , [20] , [21] & [22] .

- Ensure there are 10 chain links located between the timing marks on both camshaft sprockets [19] & [20] .

- Ensure there are 22 chain links located between the timing marks on both camshaft sprockets [15] & [19] .

- Ensure there are 22 chain links located between the timing marks on both camshaft sprockets [15] & [20] .

- Remove camshaft alignment tools.

- Set the timing chain tensioners before installation:

- Using tensioner plunger resetting tool, turn tensioner plunger clockwise while pushing inward until locked in position [23] .

- Insert tensioner plunger fully into tensioner body [24] .

- Insert tensioner locking pin into tensioner body [25] .

- To release tensioner plunger after installation:

- Remove tensioner locking pin [25] .

- Press tensioner rail briefly against tensioner to unlock tensioner plunger.