Special tools

- Camshaft locking tool – No.T10068A.

- AXZ/BHK/BHL: Crankshaft pulley holding tool – No.T10069.

- BWS: Crankshaft pulley holding tool – No.T10172.

- High-pressure fuel pump sprocket locking tool (with mechanical vacuum pump) – No.T10362.

- High-pressure fuel pump sprocket locking tool (without mechanical vacuum pump) – No.T10332.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

NOTE: If reusing timing chains: Mark direction of rotation on chains.

- Removal/installation of timing chain requires:

- Engine removal.

- Transmission removal.

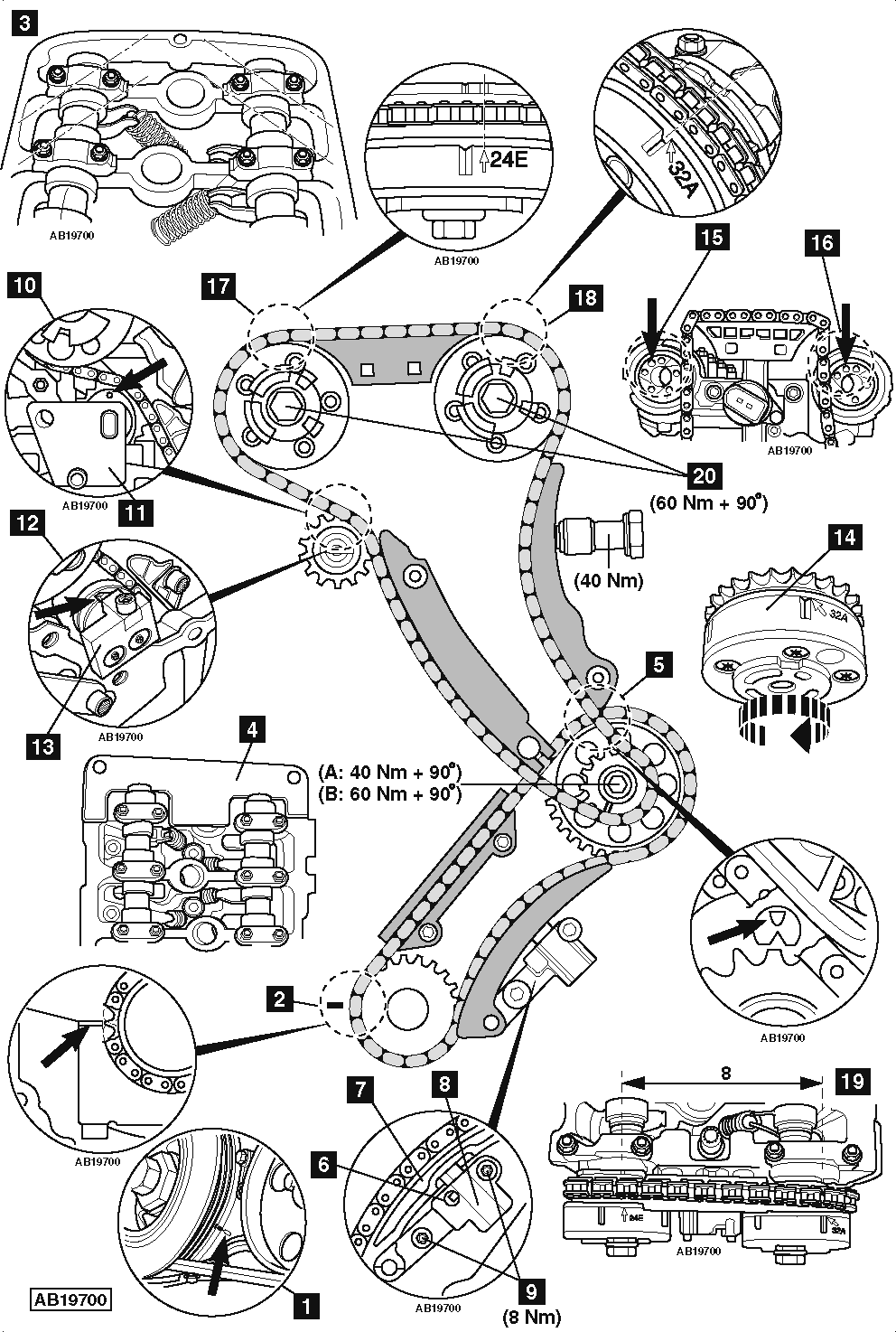

- Engine at TDC on No.1 cylinder [1] .

NOTE: Ground tooth on crankshaft sprocket aligned with rear main bearing joint [2] .

- Ensure camshaft lobes for No.1 cylinder are positioned as shown [3] . If not, turn crankshaft 360°.

- Fit camshaft locking tool [4] .

- Ensure intermediate shaft sprocket timing marks aligned [5] .

- Remove tensioner(s) to ease timing chain removal/installation.

NOTE: If replaced, ensure correct tensioner fitted.

- Reset lower timing chain tensioner:

- Release locking mechanism [6] . Use screwdriver.

- Push tensioner rail [7] against chain tensioner [8] .

NOTE: Lower timing chain tensioner bolts [9] MUST only be used once.

- Tighten tensioner bolts [9] . Tightening torque: 8 Nm.

NOTE: Renew intermediate shaft sprocket bolt.

- Tighten intermediate shaft sprocket bolt:

- A-AXZ: 40 Nm + 90°

- B-BHK/BHL/BWS: 60 Nm + 90°

- Models with mechanical vacuum pump:

- Ensure high-pressure fuel pump sprocket timing mark at 12 o’clock position [10] .

- Fit high-pressure fuel pump sprocket locking tool [11] .

- Models without mechanical vacuum pump:

- Ensure notch on high-pressure fuel pump sprocket at 12 o’clock position [12] .

- Fit high-pressure fuel pump sprocket locking tool [13] .

- Set inlet camshaft position actuator as follows:

- Turn inlet camshaft position (CMP) sensor reluctor fully clockwise as far as stop [14] .

- Fit inlet camshaft sprocket with chain. Align sprocket with hole in camshaft [15] .

- Tighten inlet camshaft position actuator bolt finger tight.

NOTE: Inlet camshaft position actuator marked 24E.

- Set exhaust camshaft position actuator as follows:

- Turn exhaust camshaft position (CMP) sensor reluctor in both directions until locked [14] .

- Fit exhaust camshaft sprocket with chain. Align sprocket with hole in camshaft [16] .

- Tighten exhaust camshaft sprocket bolt finger tight.

NOTE: Exhaust camshaft sprocket marked 32A.

- Ensure timing marks on both camshaft adjusters and on camshaft carrier aligned [17] & [18] .

- Ensure 8 links between timing marks on camshaft sprockets [19] .

NOTE: Fit new camshaft sprocket bolts.

- Install tensioner after timing chain installation.

- Remove high-pressure fuel pump sprocket locking tool [11] or [13] .

- Remove camshaft locking tool [4] .

- Turn the crankshaft two turns clockwise to No.1 cylinder at TDC [1] .

- Fit locking tool to camshafts [4] .

- Ensure timing marks aligned [17] & [18] .

- If not: Repeat timing chain installation.

- Camshaft rotation can be prevented using 27 mm spanner on hexagon.

- Tighten bolt of each camshaft sprocket to 60 Nm + 90° [20] .

NOTE: DO NOT use camshaft locking tool to prevent camshaft rotation [4] .