Skip to content

Special tools

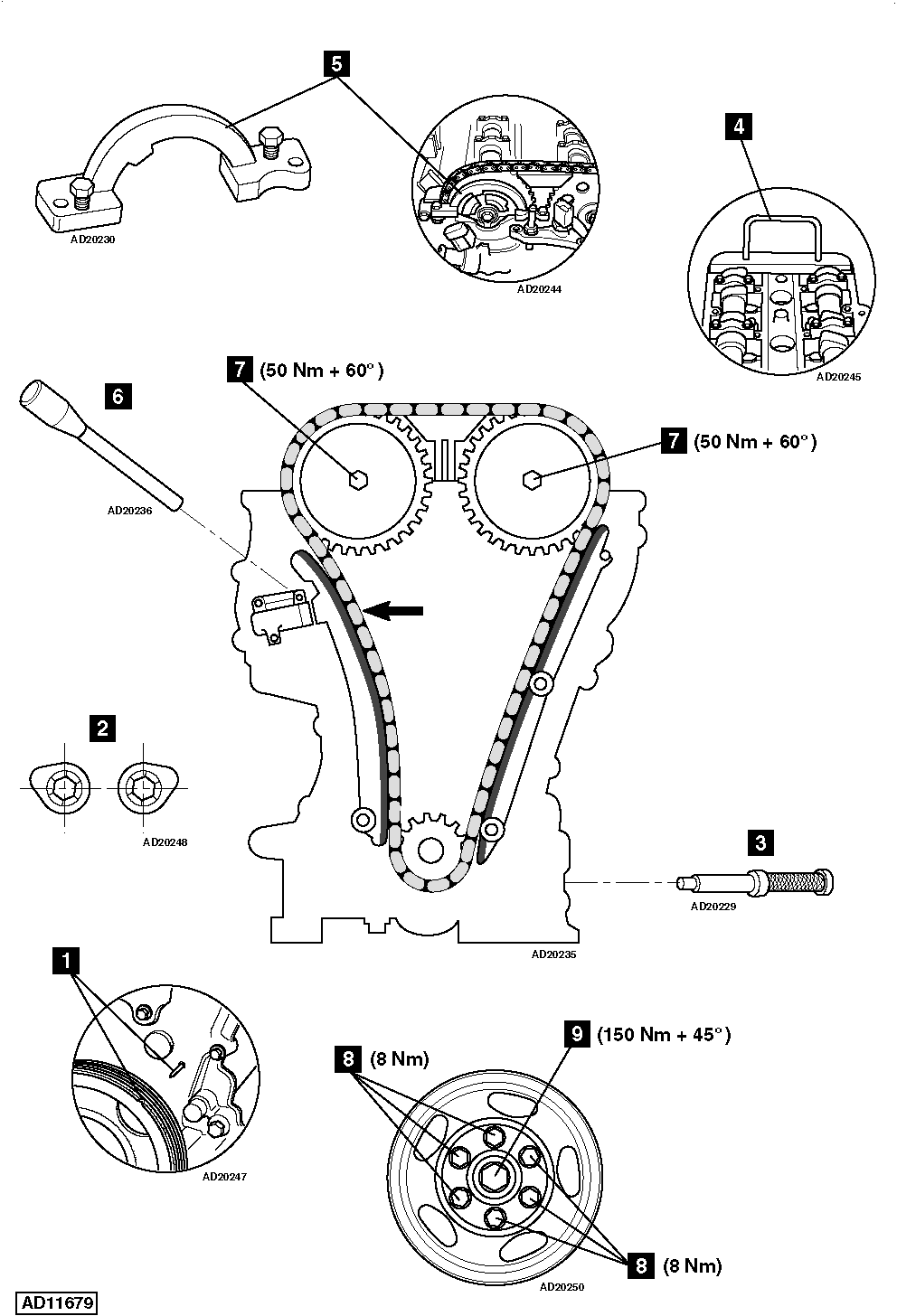

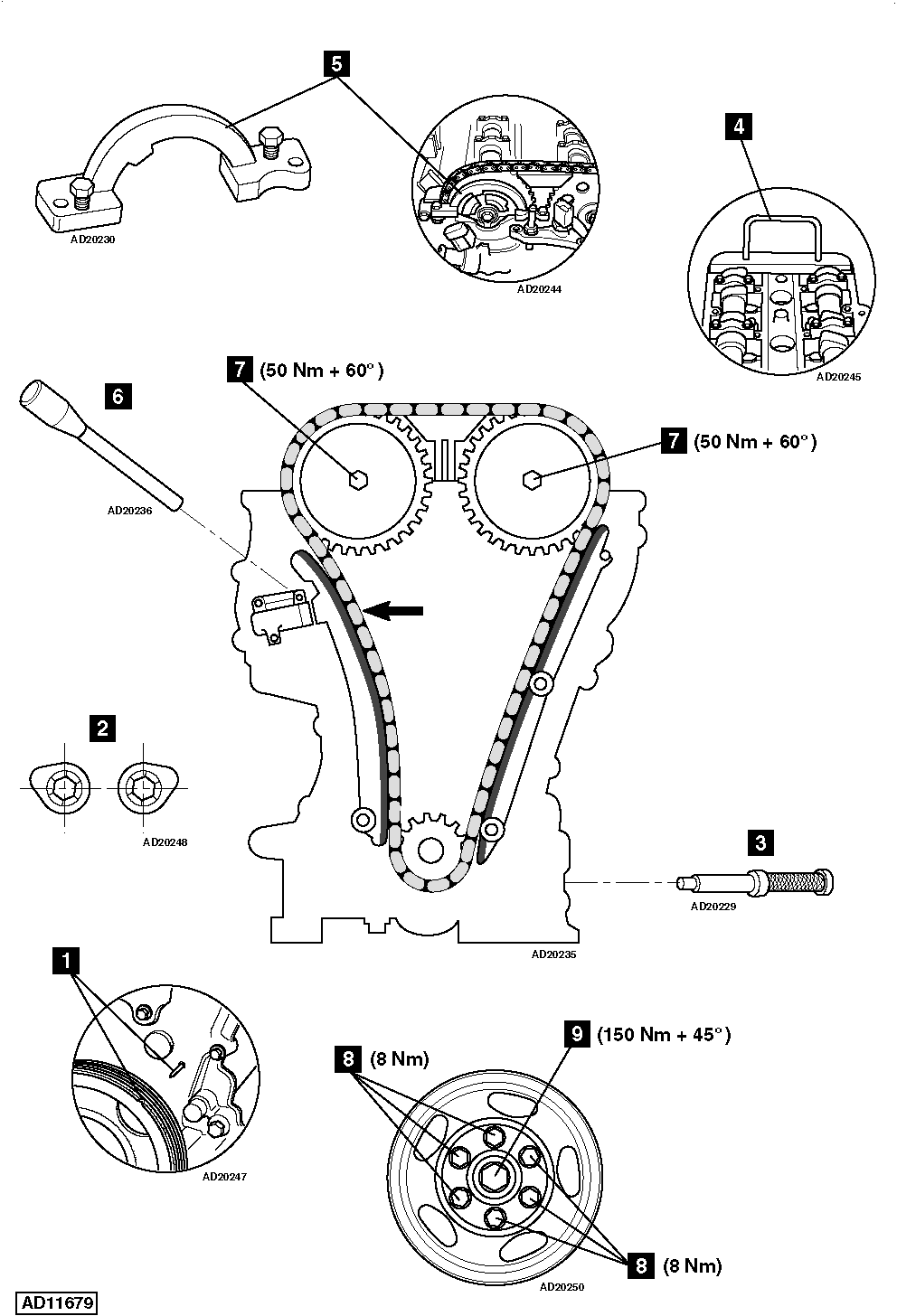

- Camshaft locking tool – No.KM-953.

- Camshaft position (CMP) sensor disc setting tool – No.KM-954.

- Crankshaft locking pin – No.KM-952.

- Timing chain tensioner locking pin – No.KM-955.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT use special tools listed above to lock engine when slackening sprocket or pulley bolts.

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

How to replace timing chain on Vauxhall/Opel Astra G 1.2i

How to replace timing chain on Vauxhall/Opel Astra G 1.2i

- Turn crankshaft until just before TDC mark on No.1 cylinder [1] .

- Ensure No.1 cylinder camshaft lobes are facing outwards [2] .

- Remove blanking plug from cylinder block.

- Slowly turn crankshaft clockwise until locking pin can be inserted in crankshaft [3] . Tool No.KM-952.

- Insert locking tool in rear of camshafts [4] . Tool No.KM-953.

- Install camshaft position (CMP) sensor disc setting tool [5] . Tool No.KM-954.

- Compress timing chain tensioner and lock with tool [6] . Tool No.KM-955.

-

If necessary, slacken bolt of each camshaft sprocket to adjust valve timing position [7] .

- Fit new bolts to camshaft sprockets [7] .

- Tighten bolt of each camshaft sprocket to 50 Nm + 60° [7] .

- Tighten crankshaft pulley bolts to 8 Nm [8] .

- Fit new crankshaft pulley centre bolt.

- Tighten crankshaft pulley centre bolt to 150 Nm + 45° [9] .