Special tools

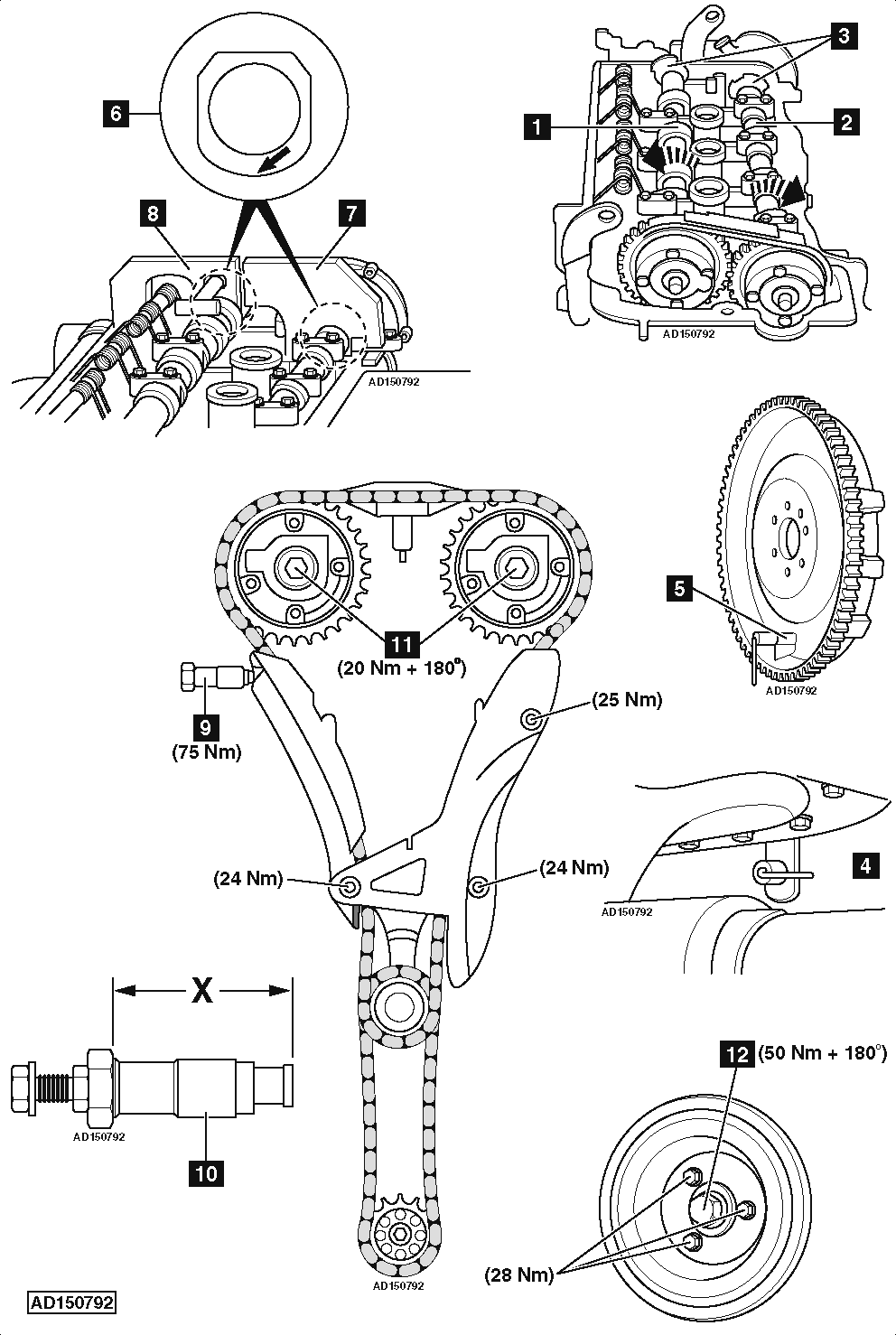

- Exhaust camshaft alignment tool – No.0197-A1.

- Flywheel timing pin – No.0197-B.

- Inlet camshaft alignment tool – No.0197-A3.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

NOTE: Engine No. →198567: This engine may suffer from premature failure of the timing chain, tensioner and guides.

- Ensure camshaft adjusters set in the installation position as follows:

- Turn crankshaft two turns clockwise.

- Turn inlet camshaft slowly anti-clockwise as far as stop [1] .

- Turn exhaust camshaft slowly clockwise as far as stop [2] .

- Camshaft rotation possible using spanner at positions shown [3] .

- Ensure camshafts locked in position.

- Replace camshaft adjuster, if not locked in installation position.

- Fit flywheel timing pin [4] .

- Turn crankshaft clockwise until flywheel timing pin engages [5] .

NOTE: Ensure round section of alignment lobe is facing downwards [6] .

- Install exhaust camshaft alignment tool [7] .

- Install inlet camshaft alignment tool [8] .

- Remove timing chain tensioner [9] .

- Modify old timing chain tensioner to use as timing chain pre-tensioning tool:

- Drill a 10,75 mm diameter hole into hexagon end of tensioner body.

- Insert M10 x 1,5 helicoil and fit M10 x 100 mm bolt with locknut.

- Install timing chain pre-tensioning tool [10] .

- Tighten adjusting screw until in contact with guide rail. DO NOT overtighten screw.

- Pre-load timing chain with pre-tensioning tool to 0,6 Nm.

- Remove camshaft alignment tools [7] & [8] .

- Remove flywheel timing pin [4] .

- Turn crankshaft two turns clockwise.

- Ensure camshaft adjusters in the installation position.

- Fit flywheel timing pin [4] .

- Ensure flywheel timing pin located correctly [5] .

NOTE: Ensure round section of alignment lobe is facing downwards [6] .

- Install exhaust camshaft alignment tool [7] .

- Install inlet camshaft alignment tool [8] .

- Timing correct when camshaft alignment tools abut cylinder head.

- If not, adjust camshafts as follows:

- Remove timing chain pre-tensioning tool [10] .

NOTE: Replace chain, tensioner and guides if ‘X’ more than 73,5 mm.

- Refit timing chain pre-tensioning tool [10] .

- Pre-load timing chain with pre-tensioning tool to 0,6 Nm.

- Remove camshaft alignment tools [7] & [8] .

- Remove central bolt from each camshaft adjuster [11] .

- Camshaft rotation can be prevented using 27 mm spanner at positions shown [3] .NOTE: Degrease ends of camshafts and camshaft sprockets.

- Fit new bolts [11] . Finger tighten bolts.

- Remove crankshaft pulley centre bolt [12] .

- Fit new crankshaft pulley central bolt [12] . Finger tighten bolt.

- Install exhaust camshaft alignment tool [7] . If necessary, adjust position of exhaust camshaft.

- Install inlet camshaft alignment tool [8] . If necessary, adjust position of inlet camshaft.

- Ensure camshaft alignment tools abut cylinder head. Secure tools with bolts.

- Tighten crankshaft pulley central bolt [12] . Tightening torque: 50 Nm + 180°.

- Tighten inlet camshaft adjuster bolt. Tightening torque: 20 Nm + 180°.

- Tighten exhaust camshaft adjuster bolt. Tightening torque: 20 Nm + 180°.

- Remove timing chain pre-tensioning tool [10] .

- Fit new timing chain tensioner. Tightening torque: 75 Nm.

- Remove camshaft alignment tools [7] & [8] .

- Remove flywheel timing pin [4] .