Special tools

- Balancer shaft alignment tool – No.651589026300.

- Camshaft alignment tools – No.651589014000.

- Crankshaft pulley holding tool – No.651589004000 or 651589084000.

- Timing chain link separator (item 1) – No.602589023300.

- Timing chain link separator (item 2) – No.602589046300.

- Timing chain link separator (item 3) – No.602589046301.

- Timing chain link installer – No.642589003300.

- Timing chain link installer die kit – No.651589046300.

- Timing chain to camshaft sprocket holder – No.651589034000.

- Tool case – No.602589009800.

General precautions

- Disconnect battery earth lead.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

NOTE: Timing chain can be changed without dismantling engine. Using the tools listed above, the new chain can be linked to the old, passed round the sprockets and then joined.

- Removal/installation of timing chain and gears requires:

- Engine removal.

- Flywheel removal.

- Sump removal.

NOTE: Timing chain and gears located at rear of engine.

- Check camshaft timing:

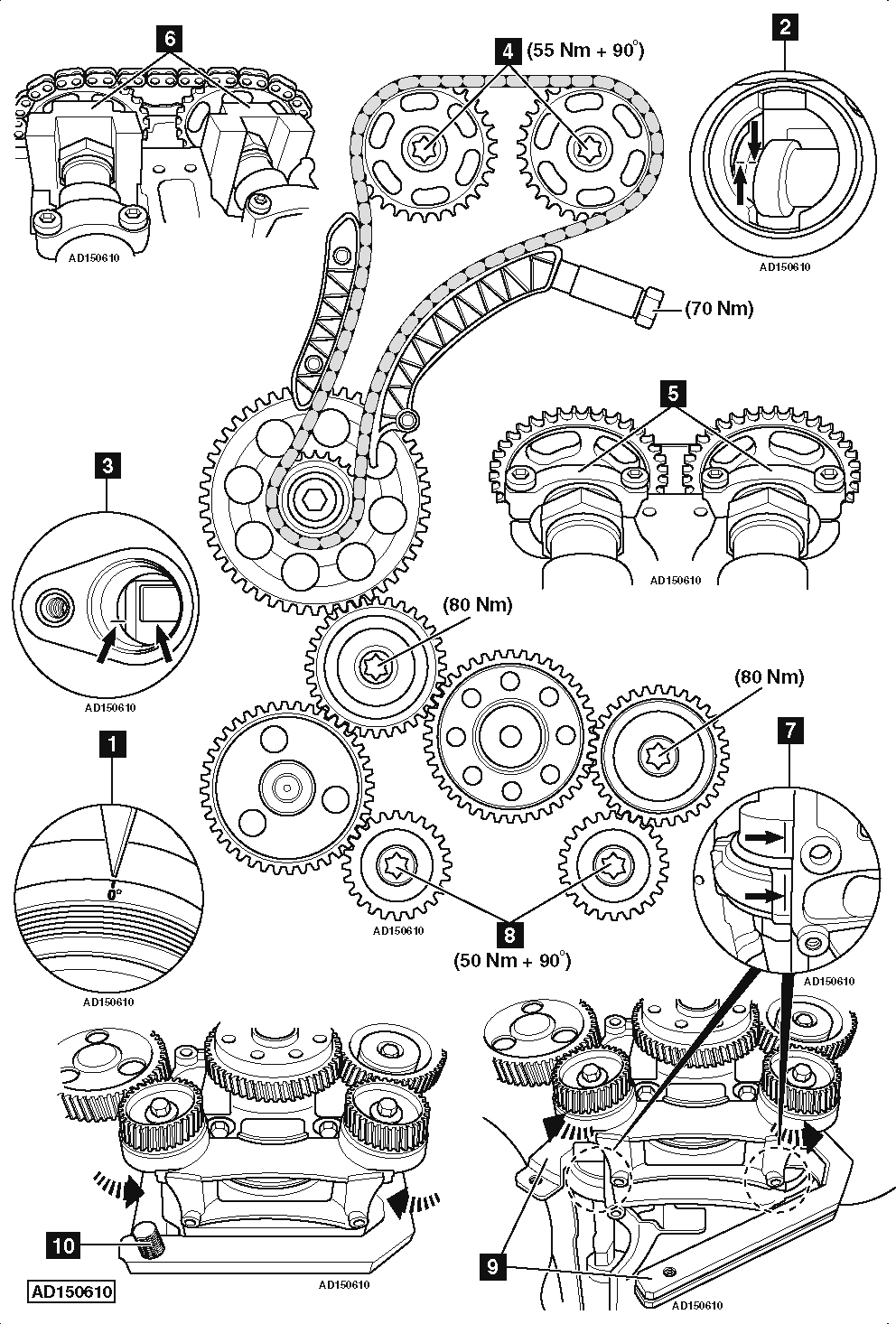

- Engine at TDC on No.1 cylinder [1] .

- Remove exhaust camshaft position (CMP) sensor.

- Ensure timing marks on camshafts aligned as shown [2] & [3] . If not, turn crankshaft 360°.

- Adjust camshafts as follows:

- Ensure crankshaft at TDC on No.1 cylinder [1] .

- Slacken bolt of each camshaft sprocket [4] .

NOTE: Camshaft sprocket bolts have LH thread.

- Remove camshaft bearing caps [5] .

- Align camshafts with camshaft alignment tools [6] .

- Tighten bolt of each camshaft sprocket [4] . Tightening torque: 55 Nm + 90°.

- Remove camshaft alignment tools [6] .

- Install camshaft bearing caps [5] .

- Check balancer shaft timing:

- Ensure crankshaft at TDC on No.1 cylinder [1] .

- Ensure balancer shaft timing mark aligned with balancer shaft housing timing mark [7] .

- Adjust balancer shafts as follows:

- Ensure crankshaft at TDC on No.1 cylinder [1] .

- Slacken bolt of each balancer shaft gear [8] .

- Rotate balancer shafts until balancer shaft alignment tool can be fitted [9] .

- Rotate balancer shafts until balancer shaft alignment tool pin can be installed [10] .

- Tighten bolt of each balancer shaft gear [8] . Tightening torque: 50 Nm + 90°.

- Remove balancer shaft alignment tool pin [10] .

- Turn crankshaft in direction of engine rotation to 30° ATDC on No.1 cylinder.

- Remove balancer shaft alignment tool [9] .