Mercedes-Benz E200 W212 1.8 2010 cambelt change instructions and replacement inteval. Full guide!

Special tools

- Balancer shaft chain link kit – No.602589024000.

- Balancer shaft chain link installer die kit – No.271589026300.

- Camshaft holding tool 1 – No.271589006100.

- Camshaft holding tool 2 (271.820/860 engines) – No.271589006100.

- Chain tensioner drift – No.271589001500.

- Crankshaft holding tool – No.271589004000.

- Crankshaft pulley puller – No.000589883300.

- Flywheel/drive plate holding tool – No.602589004000.

- Open-end spanner – No.271589000100.

- Tensioner rail wedge – No.271589003100.

- Timing chain link kit – No.271589096300.

- Timing chain link separator (item 1) – No.602589023300.

- Timing chain link separator (item 2) – No.602589046300.

- Timing chain link separator (item 3) – No.602589046301.

- Timing chain link installer – No.602589003900.

- Timing chain link installer die kit 1 – No.271589016300.

- Timing chain link installer die kit 2 – No.271589056300.

- Timing chain to camshaft sprocket holder – No.271589014000.

- Tool case – No.602589009800.

Special precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

NOTE: Timing chain can be changed without dismantling engine. Using the tools listed above, the new chain can be linked to the old, passed round the sprockets and then joined.

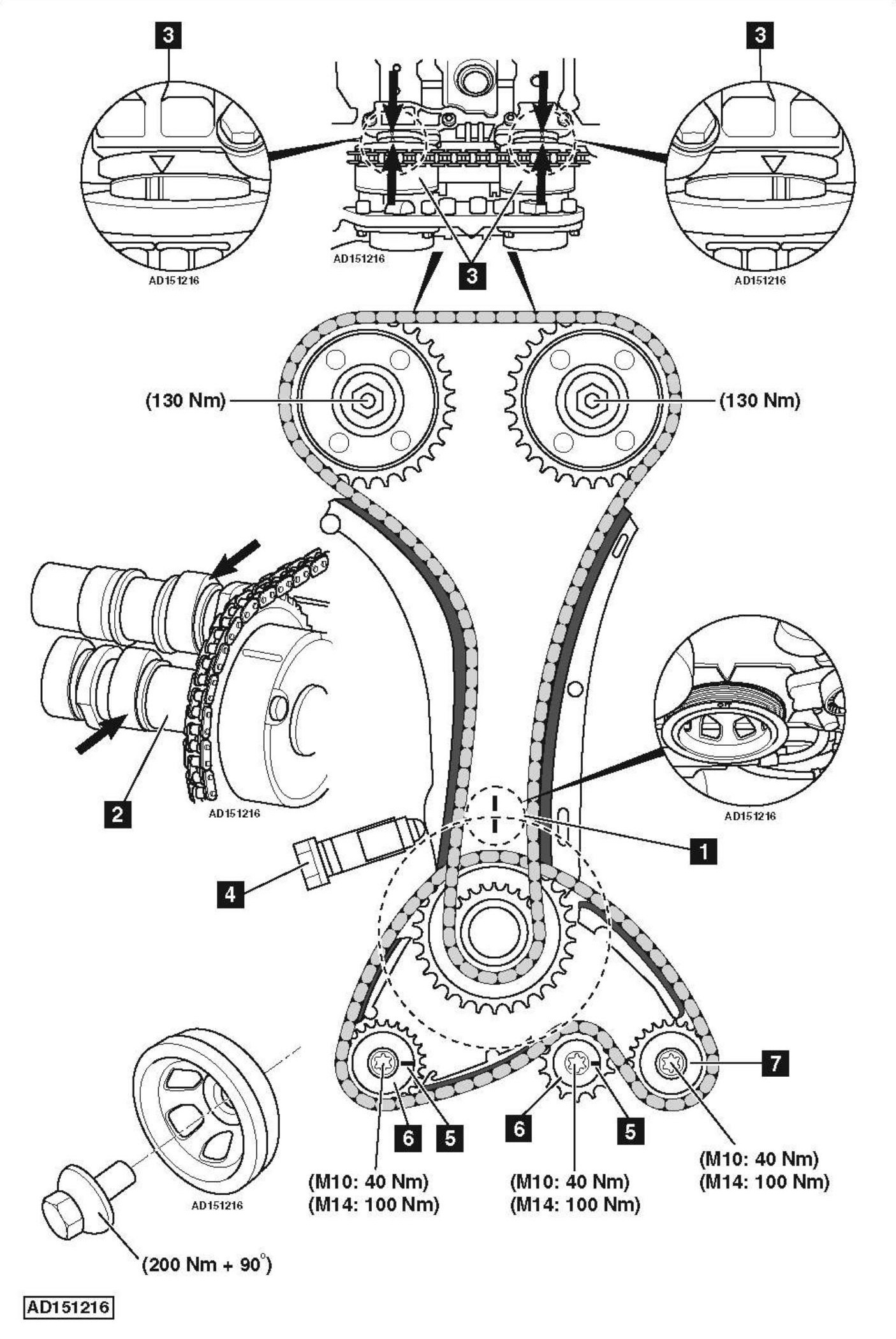

- Engine at TDC on No.1 cylinder [1] .

- Ensure No.1 cylinder camshaft lobes are facing upwards [2] .

- Ensure timing marks on both camshafts aligned [3] .

- Camshaft rotation can be prevented by using camshaft holding tool.

- Remove tensioner assembly before carrying out engine repairs [4] .

- Install tensioner after repairs. Tightening torque: 40 Nm.

- Ensure grooves [5] on sprockets of balancer shafts [6] are horizontal and pointing towards guide sprocket [7] .

-

How to Replace timing belt on Mercedes-Benz E200 W212 1.8 2010