Fiat Punto 1.6D 2012 cambelt change instructions and replacement inteval. Full guide!

Special tools

- Crankshaft timing tool – Fiat No.2.000.003.000.

- Flywheel locking tool – Fiat No.1.860.898.000.

- Holding tool – Fiat No.1.870.815.000.

- Holding tool pins – Fiat No.1.870.836.000.

- Inlet camshaft locking tool – Fiat No.1.870.896.900.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 1,90 |

Valve timing procedures

Removal

- Raise and support front of vehicle.

- Idea: Drain coolant.

- Remove:

- RH front wheel.

- Engine top cover.

- Idea: Front bumper assembly.

- Air filter housing and hoses.

- Idea: Mass air flow (MAF) sensor.

- Fuel filter assembly.

- Engine undershield.

- RH front inner wing panel.

- Auxiliary drive belt.

- Auxiliary drive belt guide pulley(s).

- Bravo/Idea: Auxiliary drive belt tensioner pulley.

- Idea: AC receiver/drier inlet pipe bracket.

- Idea: AC receiver/drier. DO NOT disconnect pipes.

- Idea: Radiator complete with fans.

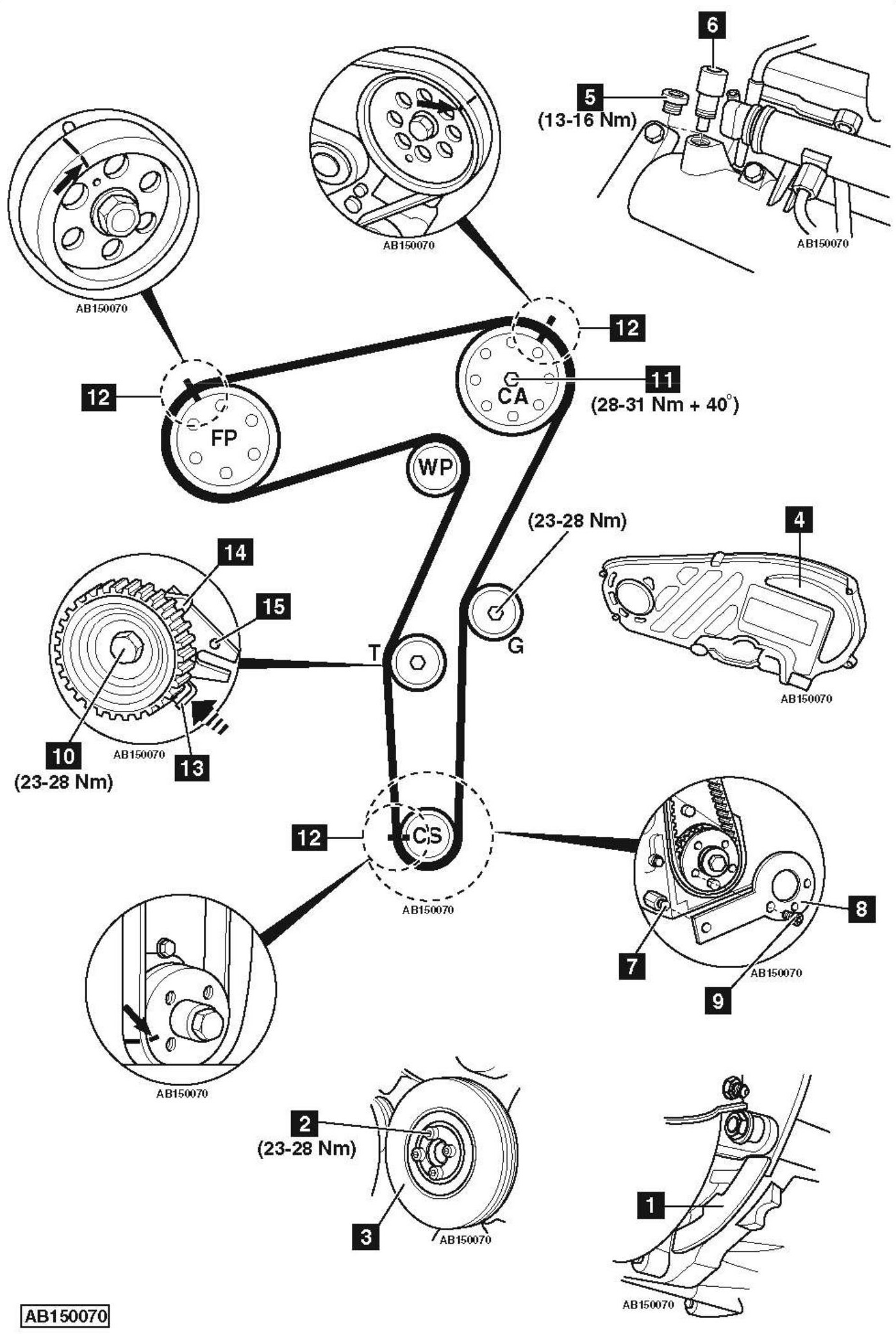

- Fit flywheel locking tool [1] . Tool No.1.860.898.000.

- Remove:

- Crankshaft pulley bolts [2] .

- Crankshaft pulley [3] .

- Support engine.

- Remove:

- Bravo/Idea: Coolant expansion tank. DO NOT disconnect hoses.

- RH engine mounting.

- Timing belt cover [4] .

- RH engine mounting bracket.

- Idea: Lower torque reaction link.

- Idea: Exhaust front pipe.

- Flywheel locking tool [1] .

- Disconnect fuel rail pressure (FRP) sensor multi-plug.

- Remove blanking plug in cylinder head for inlet camshaft locking tool [5] .

- Fit inlet camshaft locking tool [6] . Tool No.1.870.896.900.

- Turn crankshaft in direction of rotation until camshaft locking tool heard to engage [6] .

- Remove bolt from crankcase front cover. Insert stud of crankshaft timing tool [7] . Tool No.2.000.003.000.

- Temporarily fit timing tool to crankshaft sprocket [8] . Ensure pin on crankshaft sprocket located correctly in tool. Secure with bolt [9].

- Remove crankshaft timing tool [8] .

- Slacken tensioner sprocket bolt [10] .

- Move tensioner sprocket away from belt. Lightly tighten bolt.

- Remove timing belt.

Installation

- Hold camshaft sprocket. Use tool Nos.1.870.815.000/1.870.836.000.

- Slacken camshaft sprocket bolt [11] .

- Ensure camshaft sprocket can turn freely without tilting.

- Ensure inlet camshaft locking tool fitted correctly [6] .

- Ensure crankshaft timing tool can be fitted correctly [8] .

- Fit timing belt in clockwise direction, starting at crankshaft sprocket. Ensure belt is taut between sprockets on non-tensioned side.

- Ensure timing belt marks aligned [12] .

NOTE: Direction of rotation arrows on belt are between crankshaft sprocket and tensioner sprocket. - Fit crankshaft timing tool [8] . Ensure pin on crankshaft sprocket located correctly in tool. Secure with bolt [9] .

- Slacken tensioner sprocket bolt [10] .

- Lever tensioner sprocket bracket at position [13] until pointer [14] at position shown.

- Tighten tensioner sprocket bolt [10] . Tightening torque: 23-28 Nm.

- Hold camshaft sprocket. Use tool Nos.1.870.815.000/1.870.836.000.

- Tighten camshaft sprocket bolt [11] . Tightening torque: 28-31 Nm + 40°.

- Remove:

- Crankshaft timing tool [8] .

- Inlet camshaft locking tool [6] .

- Turn crankshaft two turns clockwise to setting position.

- Slacken tensioner sprocket bolt [10] .

- Lever tensioner sprocket bracket at position [13] until pointer [14] and mark [15] aligned.

- Tighten tensioner sprocket bolt [10] . Tightening torque: 23-28 Nm.

- Turn crankshaft two turns clockwise to setting position.

- Ensure inlet camshaft locking tool can be fitted correctly [6] .

- Ensure crankshaft timing tool can be fitted correctly [8] .

- If not: Repeat tensioning procedure.

- Remove:

- Inlet camshaft locking tool [6] .

- Crankshaft timing tool [8] .

- Fit bolt to crankcase front cover. Use new bolt. Tightening torque: 8-10 Nm.

- Install:

- Flywheel locking tool [1] .

- Engine mounting bracket.

- Timing belt cover [4] .

- Crankshaft pulley [3] .

- Crankshaft pulley bolts [2] .

- Refit blanking plug [5] . Renew seal. Tightening torque: 13-16 Nm.

- Tighten crankshaft pulley bolts [2] . Tightening torque: 23-28 Nm.

- Remove flywheel locking tool [1] .

- Install components in reverse order of removal.

- Idea: Refill coolant.