Special tools

- Camshaft alignment tool – BMW No.11 6 321.

- Camshaft locking tool – BMW No.11 6 322.

- Crankshaft alignment tool – BMW No.11 6 480.

- Crankshaft locking tool – BMW No.11 8 010 (AT version GM-5).

- Crankshaft locking tool 1 – BMW No.11 8 182 (AT version 6HP-19).

- Crankshaft locking tool 2 – BMW No.11 8 183 (AT version 6HP-19).

- Crankshaft locking tool 3 – BMW No.11 8 185 (MT version).

- Flywheel timing pin 1 – BMW No.11 5 180.

- Flywheel timing pin 2 – BMW No.11 6 080.

- Timing chain tensioner locking pins – BMW No.11 3 340.

General precautions

- Disconnect battery earth lead.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

- Removal/installation of timing chain requires:

- 6 cylinders: Engine removal.

- Cylinder head removal.

- Sump removal.

NOTE: Refer to Autodata Technical Data for tightening sequence and torques.

NOTE: Refer to Technical Data module for tightening torques.

- Engine at TDC on No.1 cylinder.

- Remove blanking plug from cylinder block.

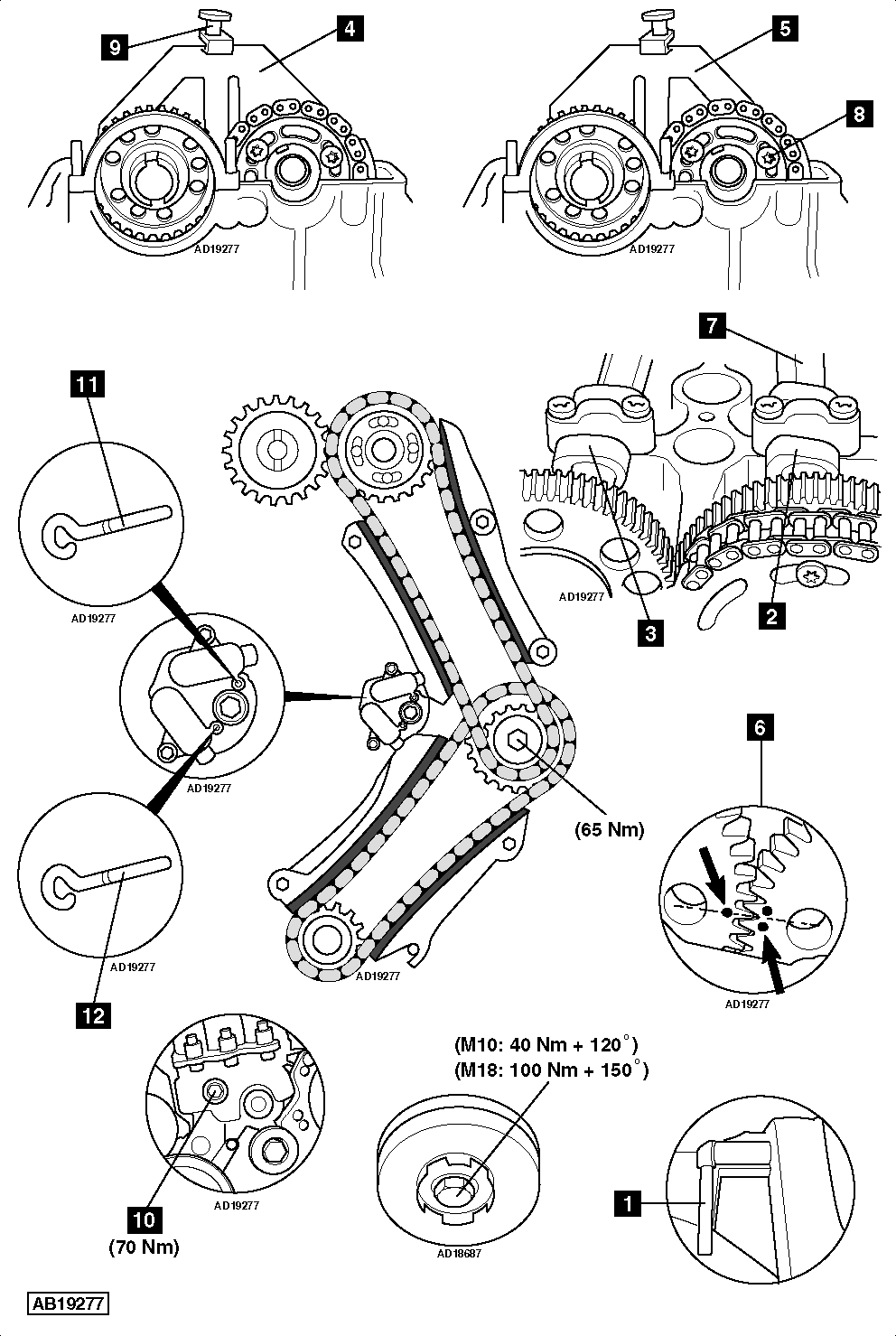

- Insert flywheel timing pin [1] .

- Ensure camshaft lobes are positioned as shown [2] & [3] .

- Install camshaft alignment/locking tool on inlet camshaft [4] .

- Ensure camshaft alignment/locking tool abuts cylinder head.

- Install camshaft alignment/locking tool on exhaust camshaft [5] .

- Ensure camshaft alignment/locking tool abuts cylinder head.

- Ensure timing marks on rear of camshaft gears aligned with upper edge of cylinder head [6] .

- If not, adjust camshafts as follows:

- Hold inlet camshaft with spanner on hexagon [7] .

- Slacken inlet camshaft sprocket bolts [8] .

- Align inlet camshaft. Use camshaft alignment tool [4] .

- Ensure camshaft alignment tool abuts cylinder head.

- Lock inlet camshaft alignment tool in position with locking tool [9] .

- Tighten camshaft sprocket bolts [8] :

- Tightening torque: 4 cylinders – 15 Nm. 6 cylinders – 14 Nm.

NOTE: Camshaft sprocket bolts MUST only be used once.

- Camshaft rotation can be prevented using spanner at position shown [7] .

- Remove flywheel timing pin.

- Remove camshaft alignment/locking tool.

- Turn crankshaft two turns clockwise. Check valve timing.

- To lock upper timing chain tensioner:

NOTE: Only upper timing chain tensioner can be reset with front timing chain cover in place.

- Remove blanking plug [10] .

- Turn inlet camshaft slowly clockwise to compress the upper timing chain tensioner.

- Camshaft rotation possible using spanner on hexagon [7] .

- Insert timing chain tensioner locking pin [11] .

- To lock lower timing chain tensioner:

- Remove timing chain cover.

- Compress tensioner plunger. Fit timing chain tensioner locking pin [12] .

- To unlock timing chain tensioners:

- Remove locking pins [11] & [12] .

- Fit new crankshaft pulley central bolt.

- Tightening torque: M10 – 40 Nm + 120°. M18 – 100 Nm + 150°.

NOTE: Camshafts can be turned without valves contacting pistons when crankshaft is set at 45° BTDC on No.1 cylinder.