Audi S3 2.0 TFSI 2008 cambelt change instructions and replacement inteval. Full guide!

Special tools

- Auxiliary drive belt tensioner locking pin – Audi No.T10060A.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 2,90 |

Valve timing procedures

Removal

- Raise and support front of vehicle.

- Remove:

- Engine undershield.

- RH front wheel.

- RH front inner wing panel.

- Engine top cover.

- S3: Engine lower torque reaction link.

- Drain cooling system.

- Disconnect fuel vapour hose from evaporative emission (EVAP) canister.

- Move evaporative emission (EVAP) canister to one side.

- Remove evaporative emission (EVAP) canister bracket.

- Disconnect coolant expansion tank multi-plugs.

- Disconnect coolant hose from timing belt upper cover.

- Unclip coolant expansion tank lower hose.

- Remove:

- S3: Windscreen washer reservoir filler neck.

- Coolant expansion tank.

- Auxiliary drive belt. Use tool No.T10060A.

- Auxiliary drive belt tensioner.

NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

- Support engine.

- Remove:

- RH engine mounting [1] .

- RH engine mounting bracket bolts [2] .

- RH engine mounting bracket [3] .

- S3: Turbocharger to intercooler pipe.

NOTE: Engine may need to be raised/lowered slightly

- Remove timing belt upper cover [4] .

- Turn crankshaft clockwise to TDC on No.1 cylinder.

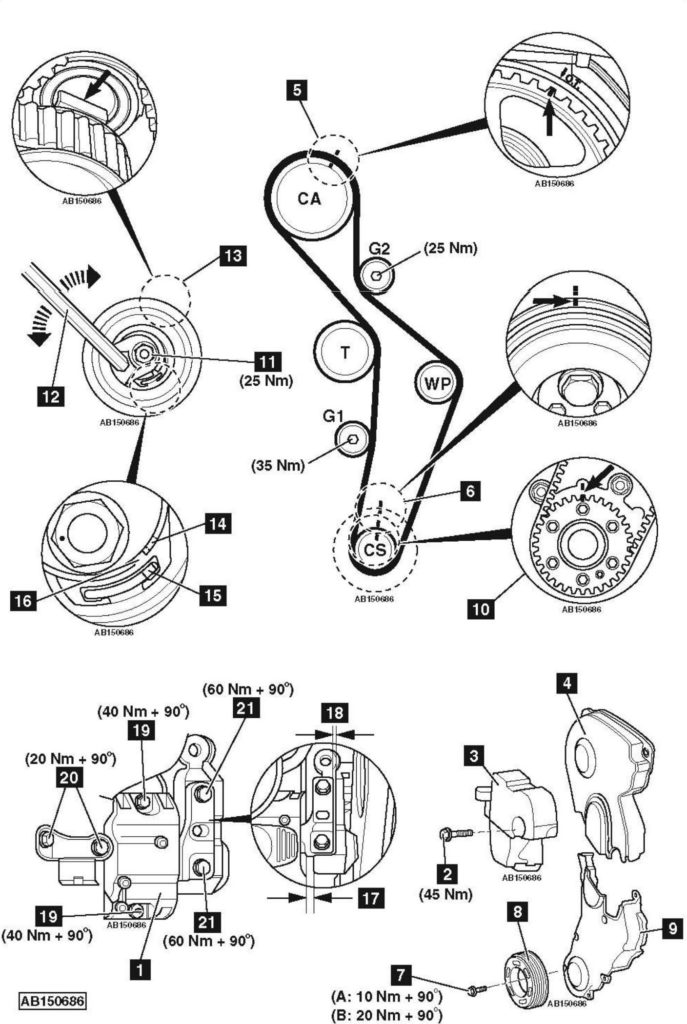

- Ensure timing marks aligned [5] & [6] .

- Remove:

- Crankshaft pulley bolts [7] .

- Crankshaft pulley [8] .

- Timing belt lower cover [9] .

- Mark crankshaft sprocket and cylinder block with paint or chalk [10] .

- Slacken tensioner pulley nut [11] .

- Turn tensioner pulley clockwise away from belt. Use Allen key [12] . Lightly tighten nut [11] .

- Remove timing belt.

NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

Installation

NOTE: Engine must be COLD.

- Check tensioner pulley and guide pulleys for smooth operation. Replace if necessary.

- Ensure camshaft sprocket timing marks aligned [5] .

- Ensure crankshaft sprocket timing marks aligned [10] .

- Fit timing belt in following order:

- Crankshaft sprocket.

- Guide pulley (G1).

- Tensioner pulley.

- Camshaft sprocket.

- Water pump sprocket.

- Guide pulley (G2).

NOTE: If reusing old belt, observe direction of rotation marks on belt. Ensure belt is taut between sprockets on non-tensioned side.

- Ensure retaining lug located in slot in cylinder head [13] .

- Slacken tensioner pulley nut [11] .

- Turn tensioner pulley clockwise until notch [14] is above lug [15] in baseplate. Use Allen key [12] .

- Turn tensioner pulley anti-clockwise to release tension on belt.

- Turn tensioner pulley clockwise until notch aligned with lug in baseplate [15] & [16] . Use Allen key [12] .

- Tighten tensioner pulley nut [11] . Tightening torque: 25 Nm.

- Turn crankshaft slowly two turns clockwise until timing marks aligned [5] & [10] .

NOTE: Turn crankshaft last 45° smoothly without stopping. - Ensure notch aligned with lug in baseplate [15] & [16] .

- If not:

- Slacken tensioner pulley nut [11] .

- Turn tensioner pulley clockwise until notch aligned with lug in baseplate [15] & [16] . Use Allen key [12] .

- Tighten tensioner pulley nut [11] . Tightening torque: 25 Nm.

- Ensure timing marks aligned [5] & [10] .

- If not: Repeat tensioning procedure.

- Install:

- Timing belt upper cover [4] .

- RH engine mounting bracket [3] .

- RH engine mounting bracket bolts [2] .

- Tighten RH engine mounting bracket bolts [2] . Tightening torque: 45 Nm.

- Lower engine slightly.

- Fit and align RH engine mounting:

- Engine mounting clearance: 16 mm [17] .

- Ensure engine mounting aligned parallel with engine mounting bracket [18] .

- Tighten:

- Engine mounting bolts [19] . Tightening torque: 40 Nm + 90°. Use new bolts.

- Engine mounting bolts [20] . Tightening torque: 20 Nm + 90°. Use new bolts.

- Engine mounting bolts [21] . Tightening torque: 60 Nm + 90°. Use new bolts.

- Install:

- Timing belt lower cover [9] .

- Crankshaft pulley [8] .

- Fit new crankshaft pulley bolts [7] . Tightening torque:

- A – TT: 10 Nm + 90°.

- B – S3: 20 Nm + 90°.

- Ensure timing marks aligned [5] & [6] .

- Install components in reverse order of removal.

- Refill cooling system.