Special tools

- Camshaft locking pin x 2 – No.T40060.

- Crankshaft alignment tool – No.T40049.

- Crankshaft locking pin – No.3242.

- Crankshaft pulley alignment tool – No.T40058

- Injection pump/balancer shaft locking pin – No.3359.

General precautions

- Disconnect battery earth lead.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

- Timing chains located at rear of engine.

- Removal/installation of timing chain(s) requires:

-

- Sump removal.

-

- Gearbox/drive plate removal.

-

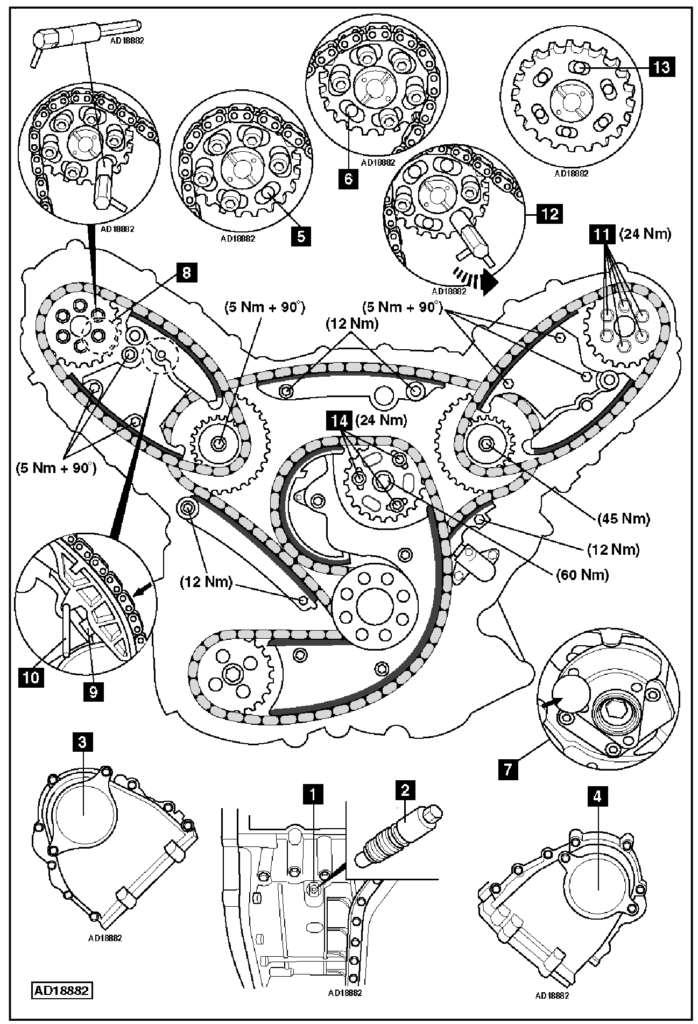

- Turn crankshaft until just before TDC on No.1 cylinder. Tool No.T40049.

- Remove blanking plug from sump [1] .

- Slowly turn crankshaft pulley clockwise until locking pin can be inserted in crankshaft [2] . Tool No.3242.

- Remove timing chain LH & RH upper covers [3] & [4] .

- Remove the camshaft sprocket bolt positioned at 5 o’clock on RH camshaft sprocket [5] .

- Remove the camshaft sprocket bolt positioned at 7 o’clock on LH camshaft sprocket [6] .

- Ensure balancer shaft can be locked in position [7] . Tool No.3359.

- Ensure both camshafts can be locked in position [8] . Tool No.T40060.

NOTE: If camshaft locking pins cannot be fitted valve timing is incorrect.

- Lock timing chain tensioners in retracted position before carrying out engine repairs:

-

- Push plunger into tensioner housing [9] .

-

- Insert 3,3 mm pin to lock tensioner plunger [10] .

-

NOTE: Upper chain tensioner bolts MUST only be used once.

- If necessary, slacken bolts of each camshaft sprocket 1 turn [11] .

- Rotate camshaft until camshaft locking pin can be fitted [8] . Tool No.T40060.

- Rotate camshaft locking pin to alignment position [12] . Tool No.T40060.

NOTE: The side pin of camshaft locking pin must be in line with centre of camshaft sprocket.

- Ensure threaded holes positioned centrally in slots of camshaft sprocket and balancer shaft sprocket [13] & [14] .

NOTE: Camshaft sprocket bolts MUST only be used once.

- Tighten camshaft sprocket bolts to 5 Nm [11] .

- Remove camshaft locking pins [8] & [12] . Tool No.T40060.

- Tighten camshaft sprocket bolts to 23 Nm [11] .

- Remove crankshaft locking pin [2] . Tool No.3242.

- Release timing chain tensioner after repairs [10] .

- Install blanking plug [1] .