Replacement Interval Guide

- Renault recommend:

- Logan/Logan MCV:

- →2008:

- Replacement every 72,000 miles or 60 months under normal conditions.

- Replacement every 54,000 miles or 60 months under adverse conditions.

- 2009:

- Replacement every 72,000 miles or 72 months under normal conditions.

- 2010→:

- Replacement every 90,000 miles or 96 months under normal conditions.

- Mégane III/Kangoo II/Kangoo Be Bop:

- Replacement every 72,000 miles or 72 months under normal conditions.

- Kangoo:

- Replacement every 72,000 miles or 60 months under normal conditions.

- Trekka 4×4:

- Replacement every 72,000 miles or 60 months under normal conditions.

- →2004: Replacement every 36,000 miles or 48 months under adverse conditions.

- All models 07/2003→:

- Tensioner pulley and guide pulley must be replaced.

- The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston damage in the event of a timing belt failure is MOST LIKELY to occur. A compression check of all cylinders should be performed before removing the cylinder head(s).

Repair Times – hrs

| Remove & install: | |

|---|---|

| Logan/Logan MCV | 2,10 |

| AC & PAS | +0,20 |

| Mégane III | 3,70 |

| Kangoo/Kangoo Trekka | 3,60 |

| Kangoo II/Be Bop | 3,90 |

| AC | -0,40 |

Special Tools

- Camshaft setting bar – Renault No.Mot.1496/1750.

- Camshaft sprocket locking tool – Renault No.Mot.1490-01.

- Crankshaft timing pin – Renault No.Mot.1489.

- Engine support tool – Renault No.Mot.1453.

- Exhaust camshaft blanking plug tool – Renault No.Mot.1488.

- Guide pulley wrench – Renault No.Mot.1368.

- Inlet camshaft blanking plug tool – Renault No.Mot.1487.

Special Precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Removal

- Raise and support front of vehicle.

- Remove:

- Engine top cover (if fitted).

- Mégane III: Throttle body assembly.

- Air resonator and air intake pipe.

- Engine undershield (if fitted).

- RH front wheel.

- RH splash guard.

- Engine lower tie-bar.

- Auxiliary drive belt.

NOTE: Auxiliary drive belt(s), tensioner pulley and guide pulley(s) MUST be replaced.

- Support engine. Use tool No.Mot.1453.

- Unclip fuel pipes and wiring harness from timing belt upper cover.

- Remove:

- Engine tie-bar and RH engine mounting assembly.

- Engine lifting eye.

- Blanking plugs from rear of camshafts.

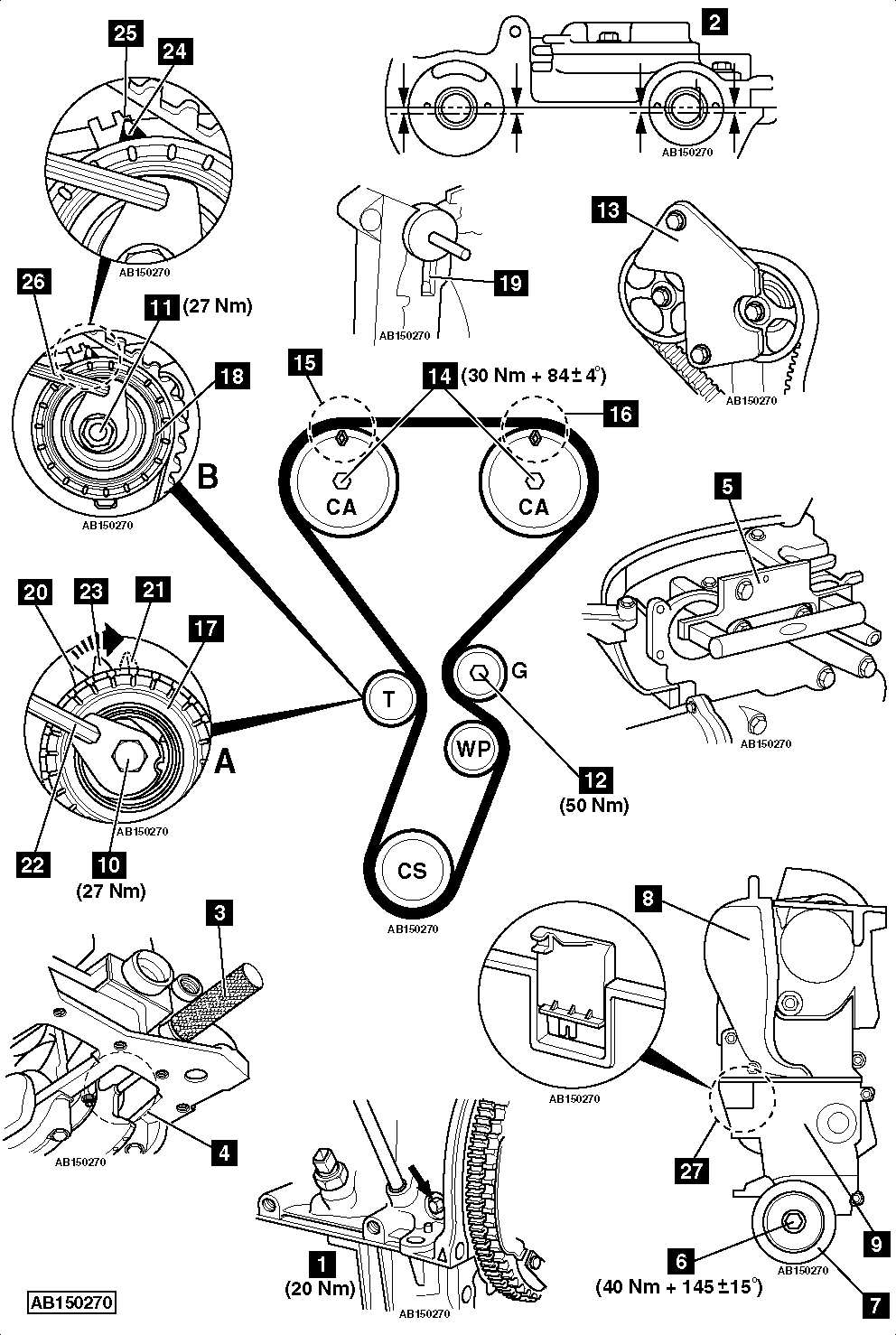

- Blanking plug from cylinder block [1] .

- Turn crankshaft clockwise to setting position. Ensure grooves in camshafts aligned [2] .NOTE: Grooves located below cylinder head upper face.

- Insert crankshaft timing pin in cylinder block [3] . Tool No.Mot.1489.

- Ensure crankshaft web against timing pin [4] .

- Remove crankshaft timing pin [3] .

- Fit setting bar to rear of camshafts [5] . Tool No.Mot.1496/1750.

- Lock flywheel with large screwdriver. Slacken crankshaft pulley bolt [6] .

- Remove:

- Crankshaft pulley bolt [6] .

- Crankshaft pulley [7] .

- Timing belt covers [8] & [9] .

- Insert crankshaft timing pin in cylinder block [3] .

- Ensure crankshaft web against timing pin [4] .NOTE: There are two types of tensioner.

- Tensioner – type A:

- Slacken tensioner pulley bolt [10] .

- Tensioner – type B:

- Slacken tensioner pulley nut [11] .

- Allow tensioner pulley to move away from belt.

- Remove:

- Guide pulley bolt [12] . Use tool No.Mot.1368.

- Guide pulley.

- Timing belt.

- Tensioner pulley.

NOTE: DO NOT allow crankshaft sprocket to fall off crankshaft.

Installation

NOTE: Timing belt, tensioner pulley and guide pulley MUST be replaced.

- Ensure crankshaft timing pin inserted [3] . Ensure crankshaft web against timing pin [4] .

- Ensure grooves in camshafts aligned [2] .

- Ensure camshaft setting bar fitted correctly [5] .

- Remove crankshaft sprocket. Degrease sprocket. Degrease end of crankshaft. Refit crankshaft sprocket.NOTE: Crankshaft keyway at 12 o’clock position.

- Fit camshaft sprocket locking tool [13] . Use tool No.Mot.1490-01.

- Remove nut of each camshaft sprocket [14] .NOTE: Replace camshaft stud if loosened when removing nut.

- Remove camshaft sprocket locking tool [13] .

- Remove camshaft sprockets. Degrease sprockets. Degrease ends of camshafts. Refit camshaft sprockets.WARNING: Failure to degrease components may lead to sprockets slipping on crankshaft and camshafts, resulting in severe engine damage.

- Lightly tighten nut of each camshaft sprocket [14] . Use new nuts.

- Ensure camshaft sprockets can turn freely without tilting.

- Ensure Renault logo on exhaust camshaft sprocket positioned as shown [15] .

- Ensure Renault logo on inlet camshaft sprocket positioned as shown [16] .NOTE: There are two types of tensioner.

- Tensioner – type A:

- Fit new tensioner pulley [17] . Lightly tighten bolt [10] . Use new bolt.

- Tensioner – type B:

- Fit new tensioner pulley [18] . Lightly tighten nut [11] . Use new nut.

NOTE: Ensure lug on rear of tensioner pulley located in groove in water pump housing [19] .

- Fit timing belt to camshaft sprockets. Ensure camshaft sprockets do not move.

- Fit camshaft sprocket locking tool [13] .

- Fit timing belt to tensioner pulley, crankshaft sprocket and water pump sprocket.

- Fit new guide pulley. Tighten guide pulley bolt [12] . Tightening torque: 50 Nm. Use tool No.Mot.1368.

- Tensioner – type A:

- Slacken tensioner pulley bolt [10] . Turn tensioner pulley clockwise until movable pointer [20] at right hand stop [21] . Use 6 mm Allen key [22] .

- Temporarily tighten bolt [10] .

NOTE: Movable pointer [20] should be 7-8 mm past fixed pointer [23] .

- Tensioner – type B:

- Slacken tensioner pulley nut [11] . Turn tensioner pulley clockwise until movable pointer [24] aligned with notch [25] . Use 6 mm Allen key [26] .

- Temporarily tighten nut [11] .

- Fit timing belt lower cover [9] .

- Remove timing belt lower cover access panel [27] .

- Ensure crankshaft web against timing pin [4] .

- Ensure setting bar fitted correctly [5] .

- Fit crankshaft pulley [7] .

- Fit new crankshaft pulley bolt [6] .

- Lock flywheel with large screwdriver. Tighten crankshaft pulley bolt [6] . Tightening torque: 40 Nm + 145±15°.

- Tighten nut of each camshaft sprocket [14] . Tightening torque: 30 Nm + 84±4°.

- Remove:

- Camshaft setting bar [5] .

- Camshaft sprocket locking tool [13] .

- Crankshaft timing pin [3] .

- Turn crankshaft two turns clockwise to setting position.

- Insert timing pin in cylinder block [3] .

- Ensure crankshaft web against timing pin [4] .

- Remove crankshaft timing pin [3] .

- Tensioner – type A:

- Ensure tensioner pointer aligned with notch [20] & [23] . Tighten tensioner pulley bolt [11] . Tightening torque: 27 Nm.

- If not: Slacken tensioner pulley bolt [10] . Turn tensioner pulley until pointer aligned with notch [20] & [23] . Use 6 mm Allen key [22] . Tighten tensioner pulley bolt [10] . Tightening torque: 27 Nm.

- Tensioner – type B:

- Ensure tensioner pointer aligned with notch [24] & [25] . Tighten tensioner pulley nut [11] . Tightening torque: 27 Nm.

- If not: Slacken tensioner pulley nut [11] . Turn tensioner pulley until pointer aligned with notch [24] & [25] . Use 6 mm Allen key [26] . Tighten tensioner pulley nut [11] . Tightening torque: 27 Nm.

- Insert timing pin in cylinder block [3] .

- Ensure crankshaft web against timing pin [4] .

- Ensure grooves in camshafts aligned [2] .

- Ensure setting bar can be easily fitted [5] . If not: Repeat installation procedure.

- Remove:

- Setting bar [5] .

- Timing pin [3] .

- Refit blanking plug [1] . Tightening torque: 20 Nm.

- Refit timing belt lower cover access panel [27] .

- Fit new blanking plugs to rear of camshafts. Use tool No.Mot.1487/1488.

- Install components in reverse order of removal.