Replacement Interval Guide

- Land Rover recommend replacement every 72,000 miles or 6 years.

- The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston damage in the event of a timing belt failure is MOST LIKELY to occur. A compression check of all cylinders should be performed before removing the cylinder head(s).

Repair Times – hrs

| Remove & install | 4,50 |

Special Tools

- Crankshaft pulley holding tool – Land Rover No.LRT-12-161.

- Crankshaft pulley holding tool handle – Land Rover No.LRT-12-199.

- Locking tools for camshafts – Land Rover No.LRT-12-196.

- Alignment plate for camshaft sprockets – Land Rover No.LRT-12-175.

- Camshaft sprocket holding tool – Land Rover No.LRT-12-195.

- Camshaft alignment pins – Land Rover No.LRT-12-198.

- Camshaft aligning tool – Land Rover No.LRT-12-197.

- Timing pin – Land Rover No.LRT-12-232.

Special Precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

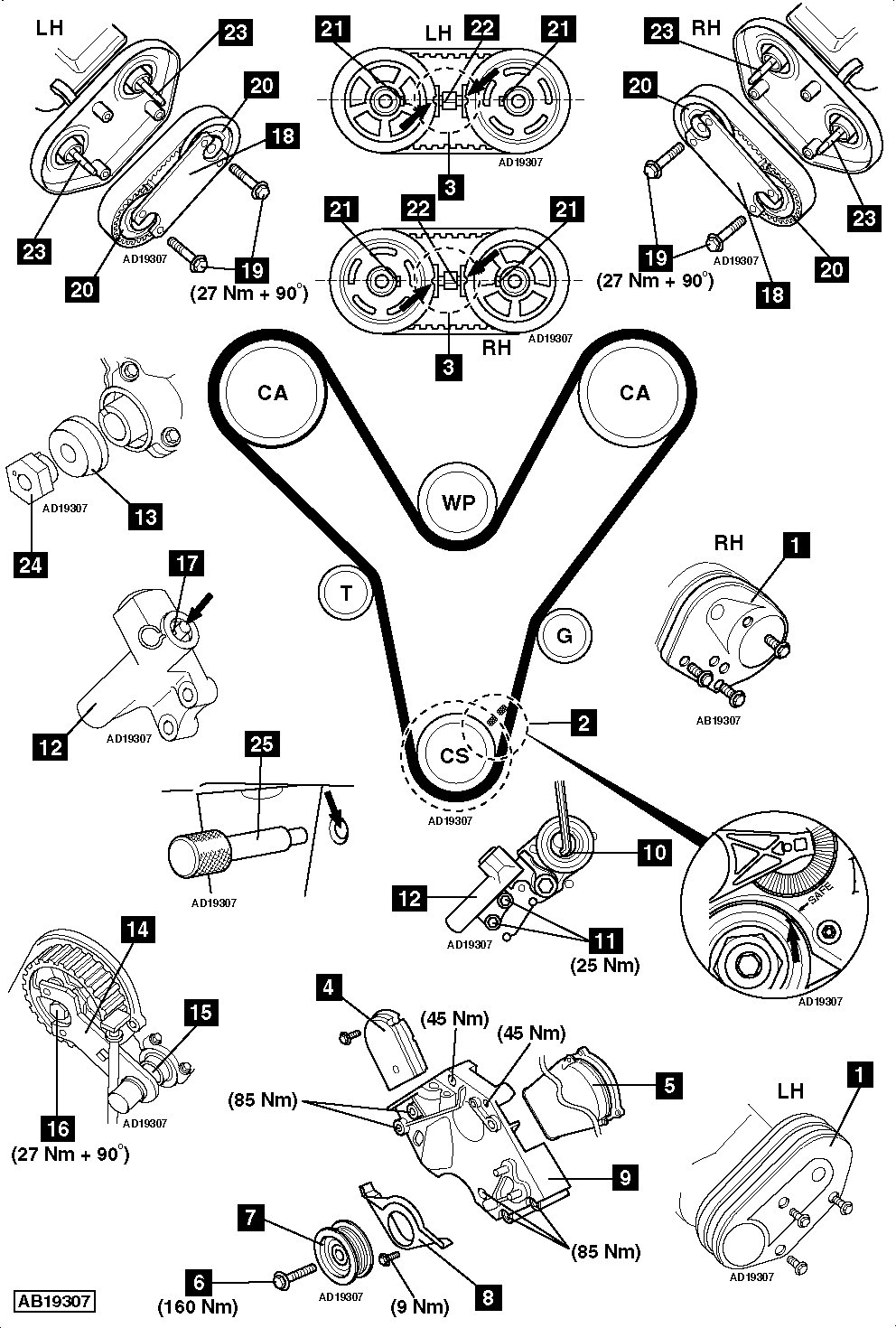

Front Timing Belt

Removal

- Raise and support front of vehicle.

- Remove:

- Engine undershield.

- RH front wheel.

- RH splash guard.

- Drain engine oil.

- Support engine.

- Remove:

- Engine top cover.

- RH engine mounting bracket.

- Auxiliary drive belt.

- Auxiliary drive belt tensioner.

- Auxiliary drive belt guide pulley.

- Alternator.

- LH rear timing belt cover [1] .

- Turn crankshaft clockwise to ‘SAFE’ position. Ensure timing marks aligned [2] .

- Ensure timing marks on camshaft rear sprockets aligned [3] .

- Insert timing pin into hole in crankcase to lock flywheel [25] . Tool No.LRT-12-232.NOTE: Hole for timing pin [25] is at front of engine closest to the cylinder block.

- Remove:

- PAS pump pulley.

- PAS pump. DO NOT disconnect hoses.

- Engine stabiliser bar.

- Timing belt covers [4] & [5] .

- Dipstick.

- Dipstick tube.

NOTE: Remove securing bolt. Depress dipstick tube locking collar and pull dipstick tube upwards.

- Hold crankshaft pulley. Use tool Nos.LRT-12-161 & LRT-12-199.

- Slacken crankshaft pulley bolt [6] .

- Remove:

- Crankshaft pulley bolt [6] .

- Crankshaft pulley [7] .

- Timing belt lower cover [8] .

- AC compressor heat shield.

- AC compressor. DO NOT disconnect hoses.

- AC compressor bracket.

- Alternator bracket.

- Engine lifting bracket.

- Engine front mounting plate [9] .

- Rubber plug from around automatic tensioner unit.

- Turn tensioner pulley away from belt. Use Allen key [10] .

- Slowly compress pushrod into tensioner body until holes aligned [17] . Retain pushrod with 1,5 mm diameter pin through hole in tensioner body.NOTE: DO NOT slacken tensioner pulley bolt.

- Remove:

- Automatic tensioner unit bolts [11] .

- Automatic tensioner unit [12] .

- Mark direction of rotation on belt with chalk if belt is to be reused.

- Remove timing belt.RH: NOTE: If cylinder heads are removed, water pump replaced, new camshaft sprockets fitted or if belt has been in use for more than 48,000 miles a new belt must be fitted.LH: NOTE: If cylinder heads are removed, water pump replaced, new camshaft sprockets fitted or if belt has been in use for more than 80.000 km a new belt must be fitted.

- Remove front oil seals from exhaust camshafts [13] .

- Lock camshaft sprockets [14] . Use tool No.LRT-12-196.

- Ensure tools located correctly on end of exhaust camshafts [15] .

- Remove bolts from camshaft sprockets [16] . DO NOT reuse bolts.WARNING: Damage to camshafts may occur if locking tools are not installed when slackening or tightening camshaft sprocket bolts.

- Remove:

- Locking tools [14] .

- Camshaft sprockets with hubs.

Installation

NOTE: If using a new automatic tensioner unit and tensioner pulley, the installation procedure is different. Refer to main dealer.

- Thoroughly clean camshaft sprockets and hubs.

- Install hubs to camshaft sprockets. Then install both assemblies to camshafts.

- Fit new bolts [16] . Tighten finger tight.

- Ensure camshaft sprockets can turn freely without tilting.

- Temporarily fit timing belt to camshaft sprockets.

- Install locking tools to camshaft sprockets [14] . Tool No.LRT-12-196.

- Ensure tools located correctly on end of exhaust camshafts [15] .

- Turn camshaft sprockets fully clockwise as viewed from front of engine.

- Ensure timing pin located correctly [25] .

- Ensure timing marks on camshaft rear sprockets aligned [3] .

- Fit timing belt in anti-clockwise direction, starting at crankshaft sprocket. Ensure belt is taut between sprockets.

- Use suitable wedge to hold belt in position at crankshaft sprocket.NOTE: Turn each camshaft sprocket anti-clockwise just enough to allow belt teeth to engage in sprocket.

- Turn tensioner pulley against belt. Use Allen key [10] .

- Install automatic tensioner unit [12] . Tighten bolts [11] . Tightening torque: 25 Nm. Use new bolts.

- Remove Allen key from tensioner pulley [10] .

- Remove pin from tensioner body to release pushrod [17] .

- Fit rubber plug to automatic tensioner unit.

- Tighten camshaft sprocket bolts [16] . Tightening torque: 27 Nm + 90°.

- Remove locking tools from camshaft sprockets [14] .

- Remove any wedges used to hold belt in position.

- Remove timing pin [25] .

- Install new oil seals on exhaust camshafts [13] .

- Turn crankshaft slowly two turns clockwise. Ensure timing marks aligned [3] .

- Ensure timing pin can be inserted easily [25] .

- Remove timing pin [25] .

- Install components in reverse order of removal.

- Tighten crankshaft pulley bolt [6] . Tightening torque: 160 Nm.

- Tighten sump plug. Tightening torque: 25 Nm.

- Refill engine oil. Capacity: 5,2 litres (includes filter).

- Tighten wheel nuts. Tightening torque: 115 Nm.

Rear Timing Belts

Removal

NOTE: The following instructions apply to both RH and LH rear timing belts. Removal and installation should only be carried out on ONE timing belt at a time.

- Raise and support front of vehicle.

- Remove:

- Engine upper cover.

- Engine undershield.

- RH front wheel.

- RH splash guard.

- Timing belt rear cover [1] .

- Inlet manifold.

- Turn crankshaft clockwise to ‘SAFE’ position. Ensure timing marks aligned [2] .

- Ensure timing marks on camshaft rear sprockets aligned [3] .

- Remove and discard front oil seal from exhaust camshaft of cylinder bank being worked on (i.e. RH or LH bank) [13] .

- Fit alignment plate to camshaft rear sprockets [18] . Tool No.LRT-12-175.

- Remove bolts [19] .

- Remove camshaft sprockets, timing belt and alignment plate as an assembly [20] .

- Remove:

- Alignment plate [18] .

- Timing belt.

RH: NOTE: Mark direction of rotation on belt with chalk if belt is to be reused. If belt has been in use for more than 48,000 miles: Fit new belt.

LH: NOTE: Mark direction of rotation on belt with chalk if belt is to be reused. If belt has been in use for more than 80.000 km: Fit new belt.

Installation

- Thoroughly clean camshaft sprockets.

- Place sprockets on a flat surface.

- Ensure timing marks on camshaft sprockets aligned [3] . Ensure lugs pointing towards each other [21] .

- Fit timing belt to sprockets. Ensure timing marks aligned [3] .

- Fit special tool between sprockets [22] . Tool No.LRT-12-195.

- Turn centre screw to separate sprockets until alignment plate can be fitted to camshaft sprockets [18] . Tool No.LRT-12-175.

- Remove special tool [22] . Tool No.LRT-12-195.

- Install alignment pins to camshafts [23] . Tool No.LRT-12-198.

- Ensure timing marks aligned [2] .

- Install camshaft sprockets, timing belt and alignment plate as an assembly [20] .

- Fit aligning tool to exhaust camshaft [24] . Tool No.LRT-12-197.

- Turn exhaust camshaft and align locating slots to sprockets. Use 30 mm socket and tool No.LRT-12-197.

- Remove alignment pins [23] . Tool No.LRT-12-198.

- Tighten camshaft sprocket bolts [19] . Tightening torque: 27 Nm + 90°. Use new bolts.

- Remove alignment plate [18] . Tool No.LRT-12-175.

- Remove aligning tool [24] . Tool No.LRT-12-197.

- Fit new oil seal [13] .

- Turn crankshaft two turns clockwise. Ensure timing marks aligned [2] & [3] .

- Install components in reverse order of removal.

- Tighten wheel nuts. Tightening torque: 115 Nm.