Special tools

- Camshaft alignment tools – BMW No.11 9 970.

- Crankshaft pulley holding tool – BMW No.11 0 280.

- Crankshaft timing pin – BMW No.11 0 480 or 11 5 320.

- Flywheel locking tool – BMW No.11 9 260.

- Flywheel locking tool adaptor – BMW No.11 9 263.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

- Removal/installation of timing chain requires:

- Sump removal.

- Oil pump removal.

- Checking LH bank valve timing:

- Engine at TDC on No.1 cylinder compression stroke.

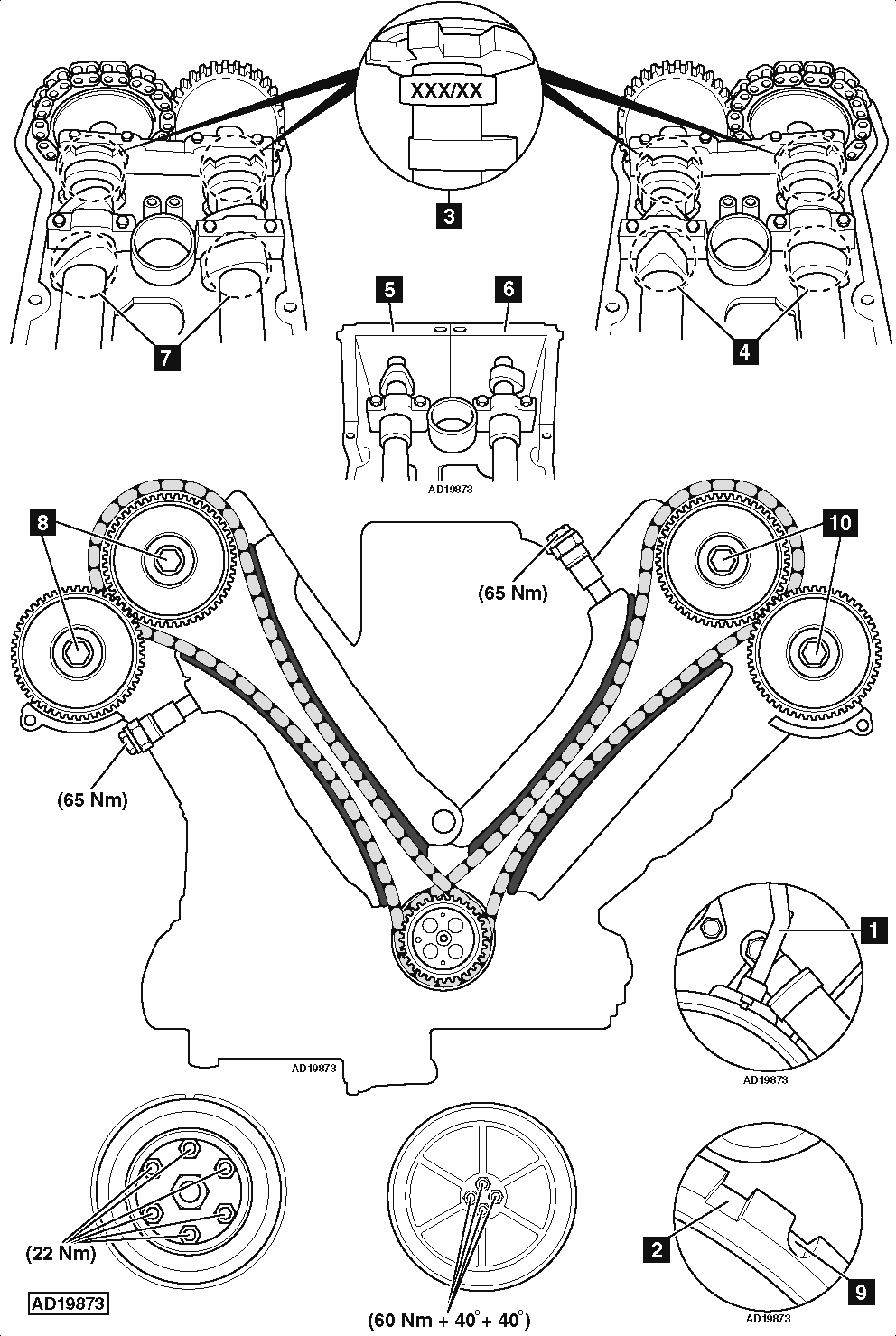

- Insert crankshaft timing pin [1] .

- Ensure crankshaft timing pin engages with TDC slot in crankshaft pulley [2] .

- Ensure part number on each camshaft is facing upwards [3] .

- Ensure camshaft lobes for No.5 cylinder are positioned as shown [4] .

- Install camshaft alignment tools [5] & [6] .

- Timing correct when camshaft alignment tools abut cylinder head or are raised up to a maximum of 1 mm on one side of each alignment tool.

- If not, adjust valve timing.

- Checking RH bank valve timing:

- Remove special tools.

- Turn crankshaft one turn clockwise.

- Engine at TDC on No.1 cylinder exhaust stroke.

- Insert crankshaft timing pin [1] .

- Ensure crankshaft timing pin engages with TDC slot in crankshaft pulley [2] .

- Ensure part number on each camshaft is facing downwards.

- Ensure camshaft lobes for No.1 cylinder are positioned as shown [7] .

- Install camshaft alignment tools [5] & [6] .

- Timing correct when camshaft alignment tools abut cylinder head or are raised up to a maximum of 1 mm on one side of each alignment tool.

- If not, adjust valve timing.

- Remove special tools.

- Adjust LH bank valve timing as follows:

- Engine at TDC on No.1 cylinder compression stroke.

- Ensure part number on each camshaft is facing upwards [3] .

- Install camshaft alignment tool to inlet camshaft [5] .

- Secure tool with bolts. Tightening torque: 10 Nm.

- Install camshaft alignment tool to exhaust camshaft [6] .

- Secure tool with bolts. Tightening torque: 10 Nm.

- Slacken bolt of each camshaft adjuster (LH thread) [10] .

- Replace bolt on each camshaft adjuster and re-tighten by hand (LH thread) [10] .

- Turn crankshaft anti-clockwise to 10° BTDC on No.1 cylinder.

- Insert crankshaft timing pin [1] .

- Ensure crankshaft timing pin engages with 10° BTDC slot in crankshaft pulley [9] .

- Tighten bolt of each camshaft adjuster in four stages [10] .

- Stage 1: Tighten bolt to 20 Nm.

- Stage 2: Tighten bolt to 80 Nm + 200°.

- Stage 3: Slacken 360°.

- Stage 4: Tighten bolt to 10 Nm.

- Tighten bolt of inlet camshaft adjuster first.

- Remove crankshaft timing pin [1] .

- Turn crankshaft clockwise to TDC on No.1 cylinder.

- Insert crankshaft timing pin [1] .

- Ensure crankshaft timing pin engages with TDC slot in crankshaft pulley [2] .

- Tighten bolt of each camshaft adjuster in two stages:

- Stage 1: Tighten bolt to 20 Nm.

- Stage 2: Tighten bolt to 80 Nm + 200°.

NOTE: Tighten bolt of inlet camshaft adjuster first.

- Adjust RH bank valve timing as follows:

- Engine at TDC on No.1 cylinder compression stroke.

- Ensure part number on each camshaft is facing upwards [3] .

- Install camshaft alignment tool to inlet camshaft [6] .

- Turn inlet camshaft slowly anti-clockwise using spanner on hexagon, until camshaft alignment tool abuts cylinder head.

- Secure tool with bolts. Tightening torque: 10 Nm.

- Install camshaft alignment tool to exhaust camshaft [5] .

- Turn exhaust camshaft slowly clockwise using spanner on hexagon, until camshaft alignment tool abuts cylinder head.

- Secure tool with bolts. Tightening torque: 10 Nm.

- Slacken bolt of each camshaft adjuster (LH thread) [8] .

- Replace bolt on each camshaft adjuster and re-tighten by hand (LH thread) [8] .

- Turn crankshaft anti-clockwise to 10° BTDC on No.1 cylinder.

- Insert crankshaft timing pin [1] .

- Ensure crankshaft timing pin engages with 10° BTDC slot in crankshaft pulley [9] .

- Tighten bolt of each camshaft adjuster in four stages [8] .

- Stage 1: Tighten bolt to 20 Nm.

- Stage 2: Tighten bolt to 80 Nm + 200°.

- Stage 3: Slacken 360°.

- Stage 4: Tighten bolt to 10 Nm.

- Tighten bolt of inlet camshaft adjuster first.

- Remove crankshaft timing pin [1] .

- Turn crankshaft clockwise to TDC on No.1 cylinder.

- Insert crankshaft timing pin [1] .

- Ensure crankshaft timing pin engages with TDC slot in crankshaft pulley [2] .

- Tighten bolt of each camshaft adjuster in two stages:

- Stage 1: Tighten bolt to 20 Nm.

- Stage 2: Tighten bolt to 80 Nm + 200°.

NOTE: Tighten bolt of inlet camshaft adjuster first.