Special tools

- Camshaft alignment tool – BMW No.11 8 760.

- Crankshaft holding tool – BMW No.11 4 320.

- Crankshaft pulley turning tool – BMW No.11 6 480.

- Flywheel/drive plate timing pin – BMW No.11 5 320.

- High-pressure fuel pump sprocket removal tool – BMW No.11 8 740.

- Tensioner locking pin – BMW No.11 3 340.

General precautions

- Disconnect battery earth lead.

- Remove glow plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

Removal

- Removal/installation of timing chain requires:

- Engine removal.

- Cylinder head removal.

- Oil pump chain removal.

- Sump removal.

NOTE: Timing chains located at rear of engine.

- Engine at TDC on No.1 cylinder.

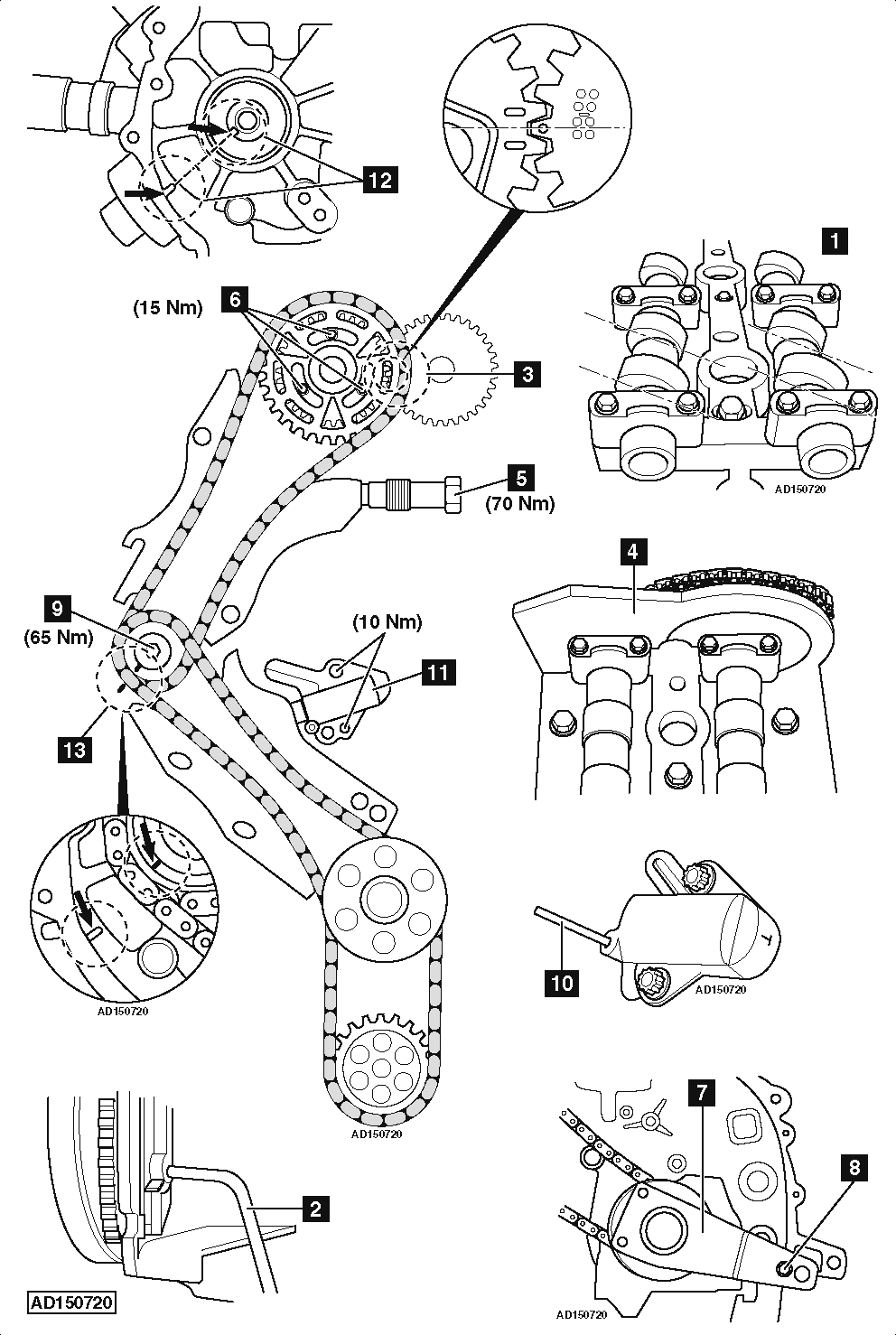

- Ensure camshaft lobes positioned as shown [1] .

- Insert flywheel/drive plate timing pin [2] .

- Ensure timing marks on rear of camshaft gears aligned [3] .

- Install camshaft alignment tool [4] .

- Ensure camshaft alignment tool abuts cylinder head.

- Remove secondary timing chain tensioner [5] .

NOTE: If chain tensioner is to be re-used it must be drained of oil. Compress plunger slowly twice.

- Slacken camshaft sprocket bolts [6] .

- Remove camshaft sprocket.

- Remove camshaft carrier assembly.

- Remove cylinder head.

- Remove secondary timing chain tensioner rail and chain.

- Install crankshaft holding tool [7] . Secure tool with bolt [8] .

- Slacken high-pressure fuel pump sprocket bolt [9] .

- Remove high-pressure fuel pump sprocket. Use high-pressure fuel pump sprocket removal tool.

- Compress primary timing chain tensioner and lock with pin [10] .

- Remove primary timing chain tensioner [11] .

- Remove primary timing chain guide and tensioner rail.

- Remove crankshaft holding tool [7] .

- Remove high-pressure fuel pump sprocket complete with primary timing chain.

Installation

- Fit primary timing chain to crankshaft sprocket.

- Install crankshaft holding tool [7] . Secure tool with bolt [8] .

- Crankshaft position set at 45° ATDC No.1 cylinder.

- Ensure groove on high-pressure fuel pump shaft aligned with lug on timing case [12] .

- Install high-pressure fuel pump sprocket.

- Ensure timing mark on high-pressure fuel pump sprocket aligned with lug on timing case [13] .

- Tighten high-pressure fuel pump sprocket bolt [9] . Tightening torque: 65 Nm.

- Install primary timing chain guide and tensioner rail.

- Install primary timing chain tensioner [11] .

- Remove tensioner locking pin [10] .

- Install secondary timing chain tensioner rail.

- Install secondary timing chain.

- Remove crankshaft holding tool [7] .

- Install oil pump chain.

- Fit timing chain cover and flywheel.

- Turn crankshaft anti-clockwise 45°.

- Insert flywheel/drive plate timing pin [2] .

- Install cylinder head.

- Ensure timing marks on rear of camshaft gears aligned [3] .

- Install camshaft carrier assembly.

- Install camshaft alignment tool [4] .

- Install camshaft sprocket.

- Temporarily tighten camshaft sprocket bolts [6] . Tightening torque: 10 Nm.

- Slacken camshaft sprocket bolts 90° [6] .

- Install secondary timing chain tensioner [5] . Tightening torque: 70 Nm.

- Tighten camshaft sprocket bolts [6] . Tightening torque: 15 Nm.

- Remove special tools [2] & [4] .

- Turn crankshaft two turns clockwise.

- Insert flywheel/drive plate timing pin [2] .

- Ensure timing marks on camshaft gears aligned [3] .

- Ensure camshaft alignment tool abuts cylinder head [4] .

- Remove special tools [2] & [4] .