Citroen Dispatch 2.0D HDi 2011-14 cambelt change instructions and replacement inteval. Full guide!

Special tools

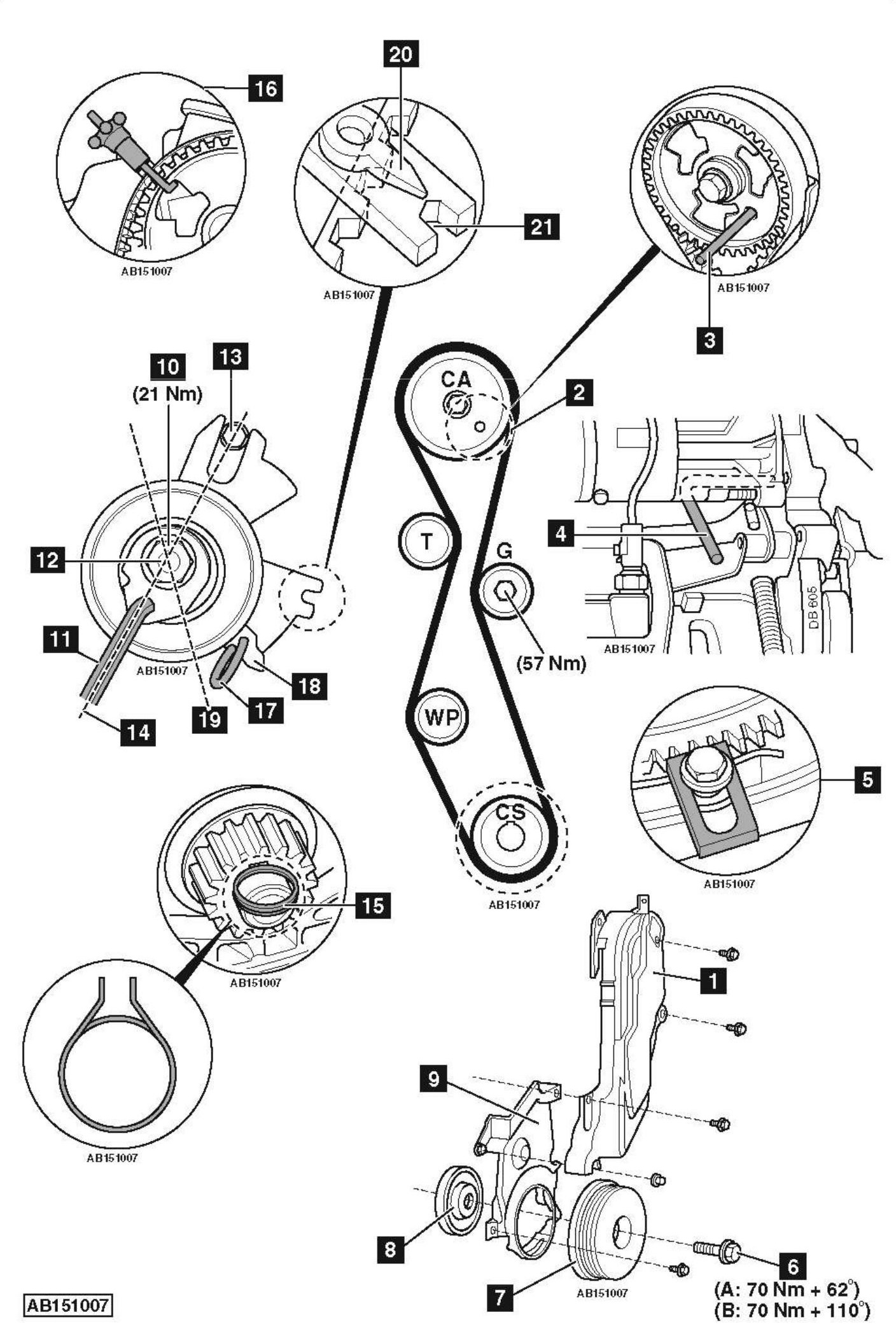

- Auxiliary drive belt tensioner tool – Citroën Nos.(-).0188.Z/Q1.

- Hybrid: Auxiliary drive belt tensioner tools – Citroën Nos.(-).1603-E/1603-F.

- Hybrid: Auxiliary drive belt tension gauge – Citroën No.(-).0107.

- Camshaft sprocket locking tool – Citroën No.(-).0188.M.

- C4 Picasso/Grand Picasso: Crankshaft reluctor puller – Citroën No.(-).0188.P.

- Crankshaft sprocket centralizing tool – Citroën No.(-).0188.AH.

- Flywheel timing pin – Citroën No.(-).0188.Y.

- Flywheel locking tool – Citroën No.(-).0188.F.

- Set of blanking plugs – Citroën No.(-).1617-J.

- Timing belt clamp – Citroën No.(-).0188.AD.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 2,60 |

Valve timing procedures

Removal

- Raise and support front of vehicle.

- Remove:

- Engine top cover.

- Engine undershield.

- Turbocharger lower air duct.

- RH front wheel.

- RH splash guard.

- Auxiliary drive belt. Use tool Nos.(-).0188.Z/Q1 or 1603-E/1603-F.

- C4 II/DS4/C4 Picasso/Grand Picasso/DS5/C8: Wiper arms.

- C4 II/DS4/C4 Picasso/Grand Picasso/DS5/C8: Scuttle panel.

- C8/Dispatch/Jumpy: Coolant expansion tank. DO NOT disconnect hoses.

- C4 Picasso/Grand Picasso: Brake fluid reservoir. DO NOT disconnect hoses.

- C4 II/DS4/C4 Picasso/Grand Picasso/DS5/C8: Scuttle panel support.

- C4 II/DS4/C4 Picasso/Grand Picasso/DS5/C8: Sound insulating pad.

- C4 II/DS4/C4 Picasso/Grand Picasso/DS5: Engine bay fuse box cover.

- Disconnect and seal off fuel pipes. Use tool No.(-).1617-J.

- Reposition priming pump.

- Remove priming pump mounting bracket.

- C8/Dispatch/Jumpy: Disconnect exhaust downpipe to centre section.

- Support engine.

- Remove RH engine mounting.

- Move aside engine wiring harness (on timing belt cover).

- Remove:

- Timing belt upper cover [1] .

- Crankshaft pulley centre cap.

- Turn crankshaft clockwise to setting position. Ensure camshaft sprocket timing hole at 4 o’clock position [2] .

- Insert:

- Camshaft sprocket locking tool [3] . Tool No.(-).0188.M.

- Flywheel timing pin [4] . Tool No.(-).0188.Y.

- Fit flywheel locking tool [5] . Tool No.(-).0188.F.

- Remove:

- Crankshaft pulley bolt [6] .

NOTE: DO NOT use an impact wrench to slacken crankshaft pulley bolt.

- Crankshaft pulley [7] .

- Disconnect crankshaft position (CKP) sensor multi-plug.

- Remove:

- Reluctor [8] . Use tool No.(-).0188.P.

- Timing belt lower cover [9] .

NOTE: Ensure reluctor is not damaged.

- Slacken tensioner pulley nut [10] .

- Turn tensioner pulley away from belt. Use Allen key [11] .

- Remove timing belt.

Installation

NOTE: DO NOT refit used belt.

- Clean crankshaft pulley bolt and crankshaft threads.

- Check guide pulley and water pump sprocket for smooth operation.

- Check crankshaft sprocket has free movement on keyway.

- Ensure flywheel timing pin located correctly [4] .

- Ensure camshaft sprocket locking tool located correctly [3] .

- If fitting new tensioner pulley:

- Remove tensioner pulley nut and stud [10] & [12] .

- Remove tensioner pulley.

- Fit new tensioner pulley.

- Ensure tensioner pulley located correctly on dowel pin [13] .

- Refit tensioner pulley nut and stud [10] & [12] .

- Ensure tensioner pulley at position shown [14] .

- Finger tighten tensioner pulley nut [10] .

- Centralise crankshaft sprocket [15] . Use tool No.(-).0188-AH.

- Secure timing belt to camshaft sprocket with clamp [16] . Use tool No.(-).0188-AD.

- Fit timing belt in clockwise direction.

- Ensure timing belt is taut between sprockets on non-tensioned side.

- Remove tensioner pulley locking pin [17] .

- If reusing tensioner pulley:

- Ensure tensioner pulley located correctly on dowel pin [13] .

- Ensure tensioner pulley at position shown [14] .

- Finger tighten tensioner pulley nut [10] .

- Centralise crankshaft sprocket [15] . Use tool No.(-).0188-AH.

- Secure timing belt to camshaft sprocket with clamp [16] . Use tool No.(-).0188-AD.

- Fit timing belt in clockwise direction.

- Ensure timing belt is taut between sprockets on non-tensioned side.

- Turn tensioner pulley anti-clockwise until pointer [18] at position shown [19] . Use Allen key [11] .

NOTE: Tensioner pulley pointer to left of notch in baseplate. - Tighten tensioner pulley nut [10] . Tightening torque: 21 Nm.

- Remove tools [15] & [16] .

- Install:

- Crankshaft pulley [7] .

- New crankshaft pulley bolt [6] .

- Tighten crankshaft pulley bolt [6] . Tightening torque: 50 Nm.

NOTE: Ensure there are less than 5 minutes between pre-tightening and final tightening of bolt. - Remove tools [3] , [4] & [5] .

- Turn crankshaft six turns clockwise.

- Install:

- Flywheel timing pin [4] .

- Camshaft sprocket locking tool [3] .

- Flywheel locking tool [5] .

- Slacken:

- Crankshaft pulley bolt [6] .

- Tensioner pulley nut [10] .

- Turn tensioner pulley clockwise until pointer aligned with notch [20] & [21] . Use Allen key [11] .

NOTE: If tensioner pulley turned too far: Turn fully anti-clockwise and repeat tensioning procedure. - Tighten tensioner pulley nut [10] . Tightening torque: 21 Nm.

- Remove tools [3] & [4] .

- Remove:

- Crankshaft pulley bolt [6] .

- Crankshaft pulley [7] .

- Install:

- Timing belt lower cover [9] .

- Reluctor [8] .

- Coat crankshaft pulley bolt with suitable thread locking compound.

- Install:

- Crankshaft pulley [7] .

- Crankshaft pulley bolt [6] .

- Tighten crankshaft pulley bolt [6] . Tightening torque:

- A – Except HYbrid4: 70 Nm + 62°.

- B – HYbrid4: 70 Nm + 110°.

NOTE: DO NOT use an impact wrench to tighten crankshaft pulley bolt.

- Remove flywheel locking tool [5] .

- Install components in reverse order of removal.