Skip to content

Special tools

- Crankshaft vibration damper holder/wrench strap – Jaguar No.303-D055.

- Crankshaft vibration damper remover – Jaguar No.303-D121.

- Crankshaft vibration damper installer – Jaguar No.303-102.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

How to replace timing chains on Jaguar S-Type 3.0 24V 1998-2008

How to replace timing chains on Jaguar S-Type 3.0 24V 1998-2008

Removal

- Removal/installation of timing chain(s) requires:

- Front crossmember removal.

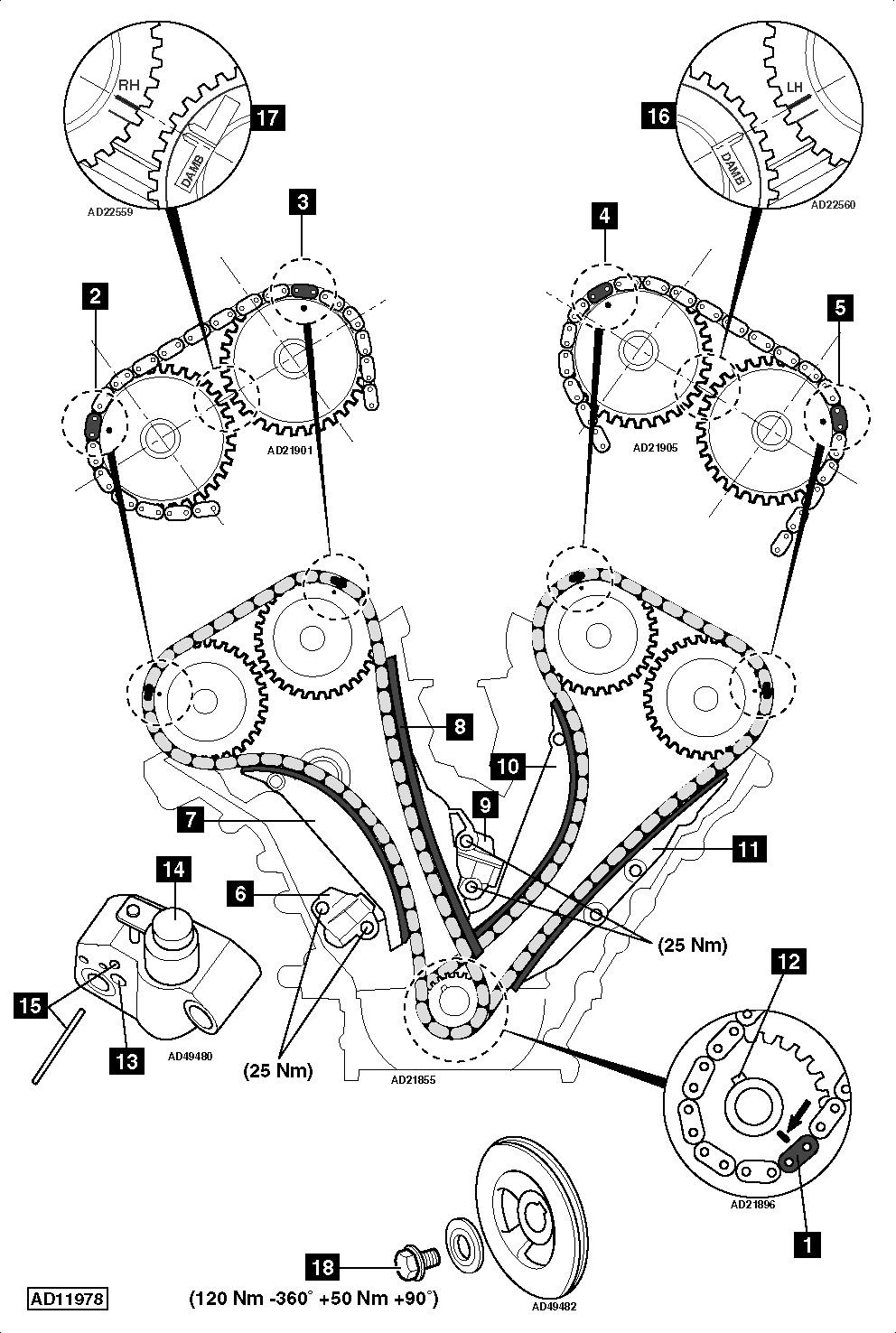

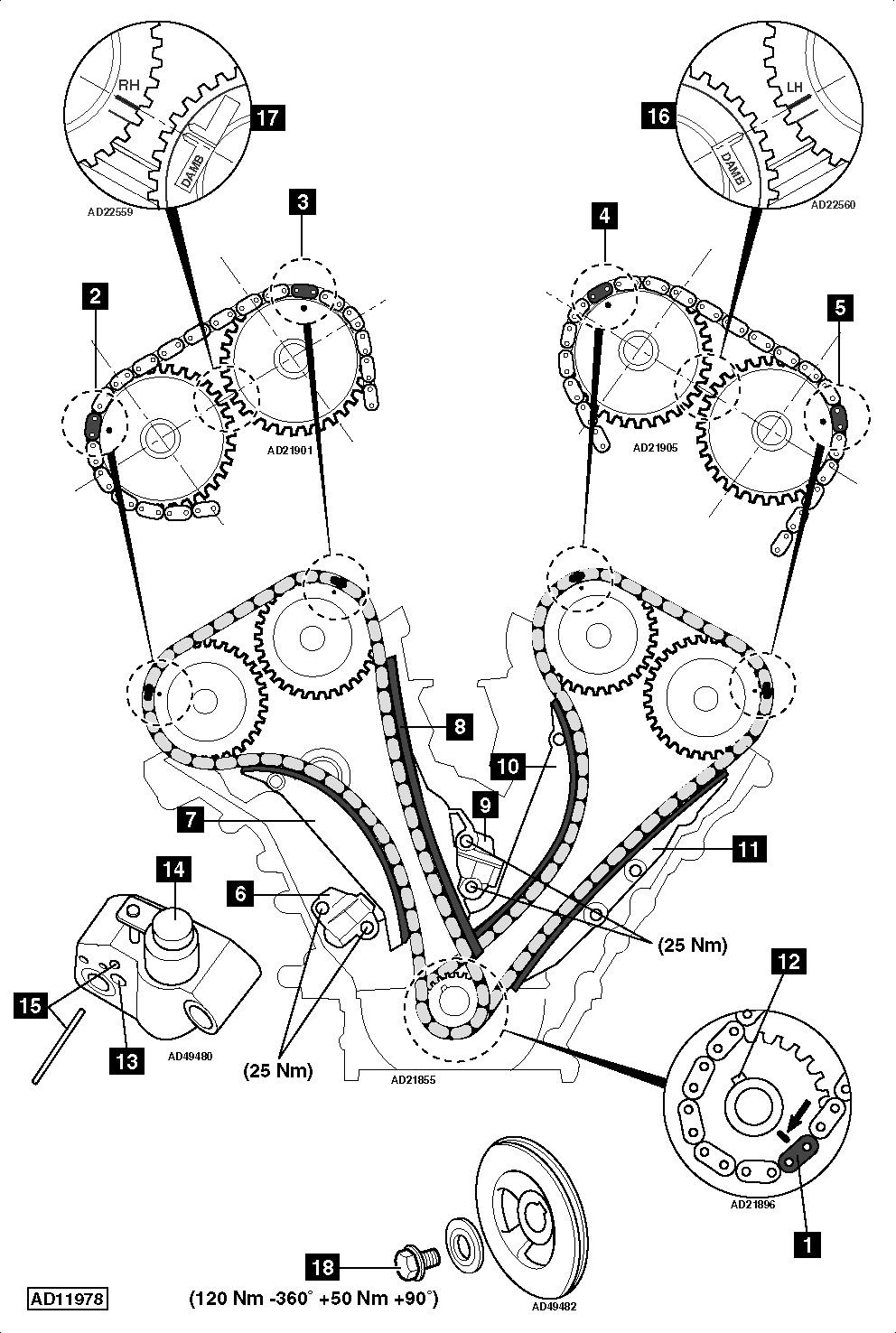

- Engine at TDC on No.1 cylinder with marked links and timing marks aligned [1] , [2] , [3] , [4] & [5] .

- Remove RH tensioner [6] , RH tensioner blade and RH chain guide [7] & [8] and RH chain.

- Remove LH tensioner [9] , LH tensioner blade and LH chain guide [10] & [11] and LH chain.

- Remove crankshaft sprockets.

Installation

- Engine at TDC on No.1 cylinder.

- Ensure crankshaft sprocket keyway at 11 o’clock position [12] .

- Set timing chain tensioners:

- Release tensioner ratchet [13] .

- Compress tensioner plunger [14] .

- Retain in position with wire clip [15] .

- Install crankshaft sprockets.

- Ensure timing marks of both LH camshaft sprockets aligned [16] .

- Install LH chain guide [11] .

- Install LH chain ensuring marked links aligned [1] , [4] & [5] .

- Install LH tensioner blade [10] .

- Install LH tensioner [9] .

- Ensure timing marks of both RH camshaft sprockets aligned [17] .

- Install RH chain guide [8] .

- Install RH chain ensuring marked links aligned [1] , [2] & [3] .

- Install RH tensioner blade [7] .

- Install RH tensioner [6] .

- Seal crankshaft pulley keyway with a proprietary sealant.

- Tighten crankshaft pulley bolt to 120 Nm slacken 360°. Tighten to 50 Nm + 90° [18] .