Hyundai Getz 1.6 2005 cambelt change instructions and replacement inteval. Full guide!

Special tools

- None required.

Special precautions

- Disconnect battery earth lead.

- DO NOT turn crankshaft or camshaft when timing belt removed.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- DO NOT turn engine via camshaft or other sprockets.

- Observe all tightening torques.

Repair times – hrs

| Camshaft drive belt/chain – R & I | 2,00 |

| Camshaft drive belt/chain, AC – R & I | 2,20 |

| Camshaft drive belt/chain, PAS+AC – R & I | 2,30 |

Valve timing procedures

Removal

- Support engine.

- Remove:

- Auxiliary drive belt(s).

- Water pump pulley.

- RH engine mounting and bracket.

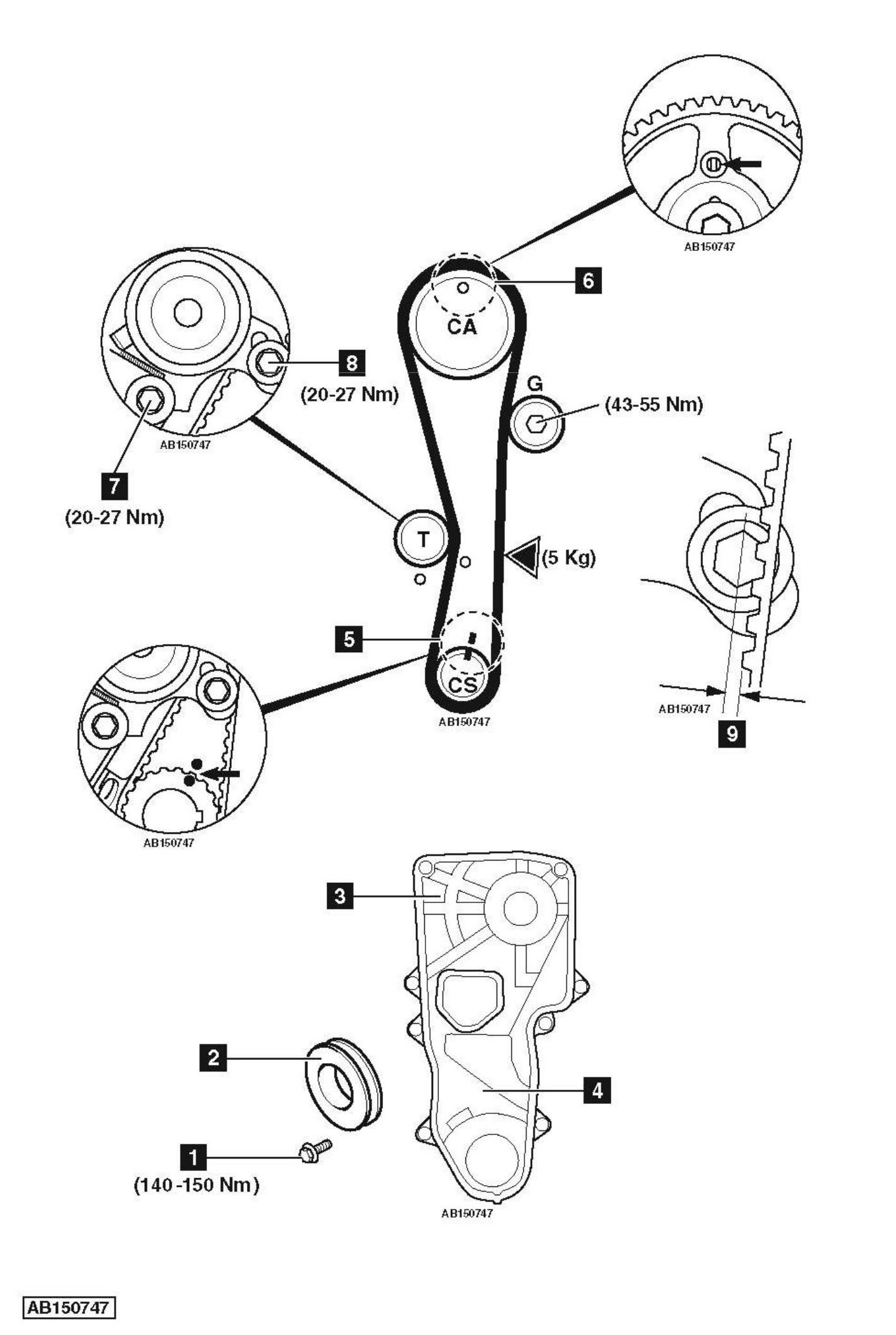

- Crankshaft bolt [1] .

- Crankshaft pulley [2] .

- Timing belt upper cover [3] .

- Timing belt lower cover [4] .

- Turn crankshaft clockwise until timing marks aligned [5] .

- Ensure hole in camshaft sprocket aligned with timing mark on cylinder head [6] .

- Slacken tensioner bolt [7] .

- Slacken tensioner bolt [8] .

- Move tensioner away from belt. Lightly tighten tensioner bolt [8] .

- Remove timing belt.

NOTE: Mark direction of rotation on belt with chalk if belt is to be reused.

Installation

- Check tensioner pulley for smooth operation.

- Ensure timing marks aligned [5] .

- Ensure hole in camshaft sprocket aligned with timing mark on cylinder head [6] .

- Fit timing belt in anti-clockwise direction, starting at crankshaft sprocket.

NOTE: Observe direction of rotation marks on belt. - Ensure belt is taut between sprockets on non-tensioned side.

- Slacken tensioner bolt [8] .

- Allow tensioner to operate.

- Tighten tensioner bolt [8] . Tightening torque: 20-27 Nm.

- Tighten tensioner bolt [7] . Tightening torque: 20-27 Nm.

- Turn crankshaft two turns clockwise.

- Ensure timing marks aligned [5] & [6] .

- Apply firm thumb pressure to belt at (5 kg).

- Belt should deflect to 1/4 of tensioner bolt head width [9] .

- Install components in reverse order of removal.

- Tighten crankshaft bolt [1] . Tightening torque: 140-150 Nm.