Special tools

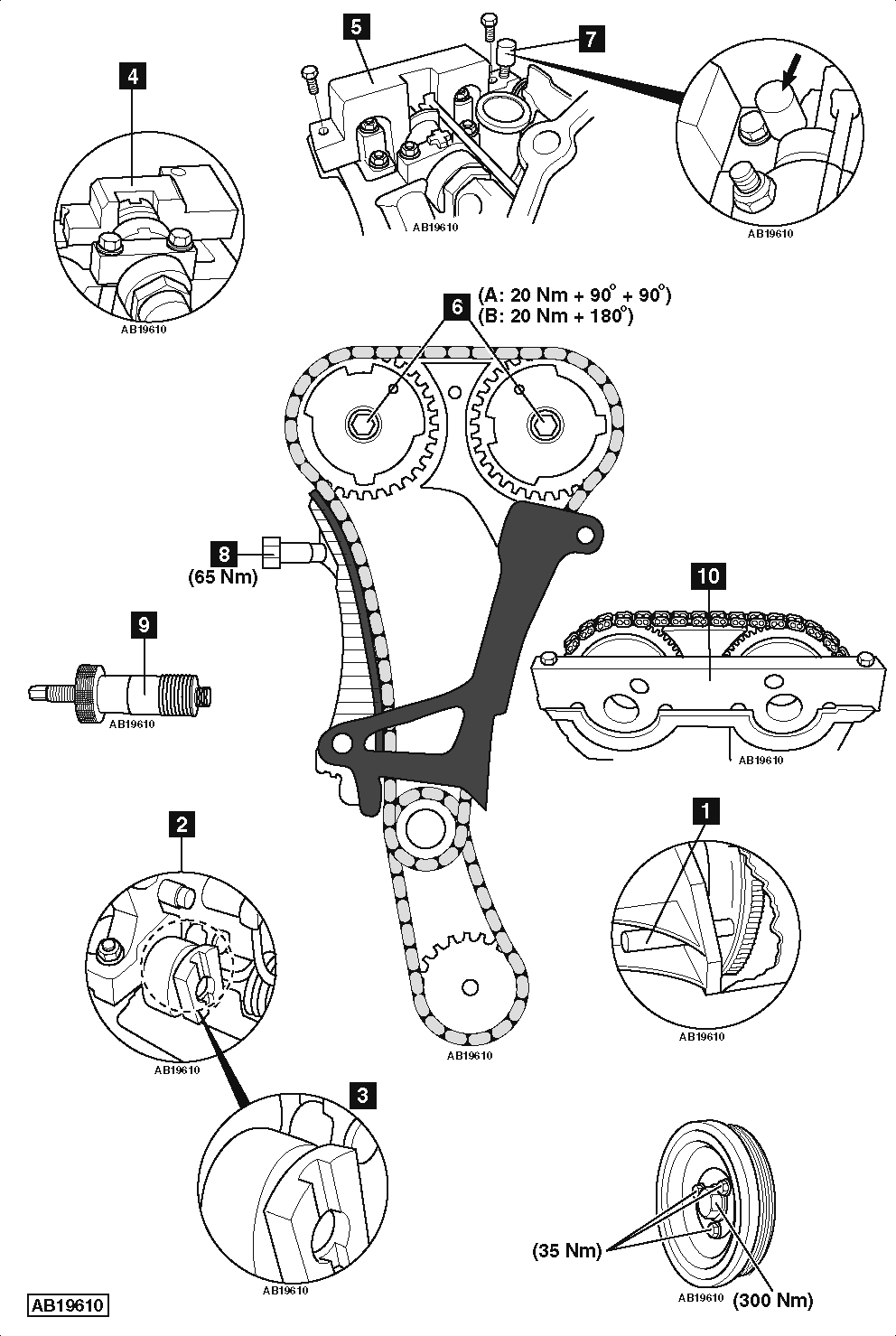

- Camshaft alignment tool 1 – BMW No.11 7 251.

- Camshaft alignment tool 2 – BMW No.11 7 252.

- Camshaft alignment tool 3 – BMW No.11 7 253.

- Flywheel timing pin 1 – BMW No.11 5 120.

- Flywheel timing pin 2 – BMW No.11 9 190.

- Sensor gear alignment tool – BMW No.11 7 260.

- Timing chain pre-tensioning tool – BMW No.11 9 340.

- Torque wrench – BMW No.00 9 250.

- Vibration damper hub holding tool – BMW No.11 9 280.

General precautions

- Disconnect battery earth lead.

- Remove spark plugs to ease turning engine.

- Turn engine in normal direction of rotation (unless otherwise stated).

- Observe tightening torques.

- If fitted: Mark position of crankshaft position (CKP) sensor before removal.

- Do NOT turn crankshaft via camshaft or other sprockets.

- Do NOT turn crankshaft or camshaft with timing chain removed.

Valve timing procedures

- Removal/installation of timing chain requires:

- Sump removal.

NOTE: Refer to Autodata Technical Data for tightening torques.

NOTE: Refer to Technical Data module for tightening torques.

- Engine at TDC on No.1 cylinder.

- Insert flywheel timing pin [1] .

- Ensure rear of camshafts correctly aligned [2] .

NOTE: Curved profile at rear of camshaft points upwards [3] .

- Install inlet camshaft alignment tool [4] .

- Install exhaust camshaft alignment tool [5] .

- Timing correct when inlet camshaft alignment tool abuts cylinder head or is raised up to a maximum of 0,5 mm on exhaust side. Timing correct when exhaust camshaft alignment tool abuts cylinder head or is raised up to a maximum of 1 mm on exhaust side.

- If not, adjust camshafts as follows:

- Slacken bolt on each camshaft adjuster and then re-tighten by hand [6] .

- Install inlet camshaft alignment tool [4] .

- Align inlet camshaft. Ensure inlet camshaft alignment tool abuts cylinder head.

- Install exhaust camshaft alignment tool [5] .

- Tighten exhaust camshaft alignment tool to cylinder head.

- Tighten bolt on exhaust camshaft alignment tool until it rests on inlet camshaft alignment tool [7] .

- Tighten inlet camshaft alignment tool to cylinder head [4] .

NOTE: Tensioner plunger is spring loaded.

- Remove tensioner [8] .

NOTE: If chain tensioner is to be reused it must be drained of oil. Compress plunger slowly twice.

- Install timing chain pre-tensioning tool [9] .

- Tighten adjusting screw until in contact with guide rail. DO NOT overtighten screw.

- Replace bolt on each camshaft adjuster and re-tighten by hand [6] .

- Install sensor gear alignment tool and secure to cylinder head [10] .

- Slacken bolt of each camshaft adjuster by half a turn [6] .

- Pre-load timing chain with tensioning tool to 0,6 Nm [9] .

NOTE: Bolt for camshaft adjusters MUST only be used once.

- Tighten bolt of each camshaft adjuster [6] .

- A – N40/N45. Tightening sequence:

- First stage – 20 Nm.

- Second stage – 90°.

- Third stage – 90°.

- B – N45T. Tightening sequence:

- First stage – 20 Nm.

- Second stage – 180°.

- Remove flywheel timing pin [1] .

- Remove sensor gear alignment tool [10] .

- Remove camshaft alignment tools [4] & [5] .

- Remove timing chain pre-tensioning tool [9] .

- Install tensioner assembly [8] . Tightening torque: 65 Nm.

- Turn crankshaft two turns clockwise.

- Ensure flywheel timing pin and camshaft alignment tools can be refitted [1] , [4] , [5] & [10] .

- Timing correct when camshaft alignment tools abut cylinder head [4] & [5] .

NOTE: Crankshaft pulley central bolt MUST only be used once.